A Method for Determining the Optimum Microstructure State of Armor-piercing Resistance of Metallic Materials

A microstructure and metal material technology, applied in the analysis of materials, using stable tension/pressure to test the strength of materials, testing the hardness of materials, etc., can solve the problems of complex armor-piercing performance testing and lack of effective material selection criteria, etc., to achieve The effect of saving experimental time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

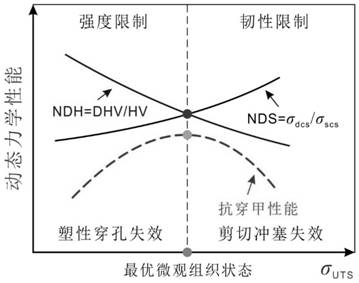

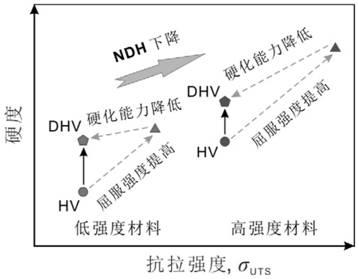

Problems solved by technology

Method used

Image

Examples

Embodiment 1

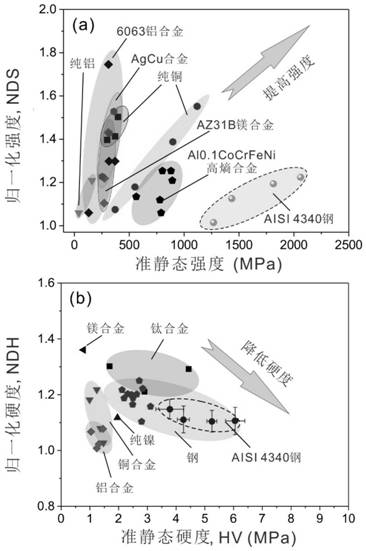

[0033] In this example, AISI 4340 steel is used as an example to determine the best microstructure method for its armor-piercing resistance. The specific steps are as follows:

[0034] Step 1: Perform different heat treatments on the original AISI 4340 steel to obtain 4 4340 steels with the same chemical composition but different microstructures (that is, different strength and toughness matching), numbered SAQ, S240, S420 and S500;

[0035] Step 2: Conduct quasi-static compression, tension and Vickers indentation experiments at room temperature with a tension and compression strain rate of 5 × 10 -4 the s -1 , the measured quasi-static compressive yield strength σ scs , tensile yield strength σ sts , tensile strength σ UTS and hardness HV (as shown in Table 1);

[0036] Step 3: Carry out room temperature high-speed compression and Vickers indentation experiments, and the strain rate of dynamic indentation experiments is 10 3 the s -1 , since the strain rate 10 was not m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com