Handheld seeder for simulating manual seeding of vegetable seeds

A hand-held, seeder technology, applied in manual sowing tools, spaced quantitative sowing machinery, sowing, etc., can solve the problems of reducing the survival rate of vegetable seeds, unfavorable batch picking, and uneven planting, so as to achieve easy picking and convenient planting. The effect of planting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

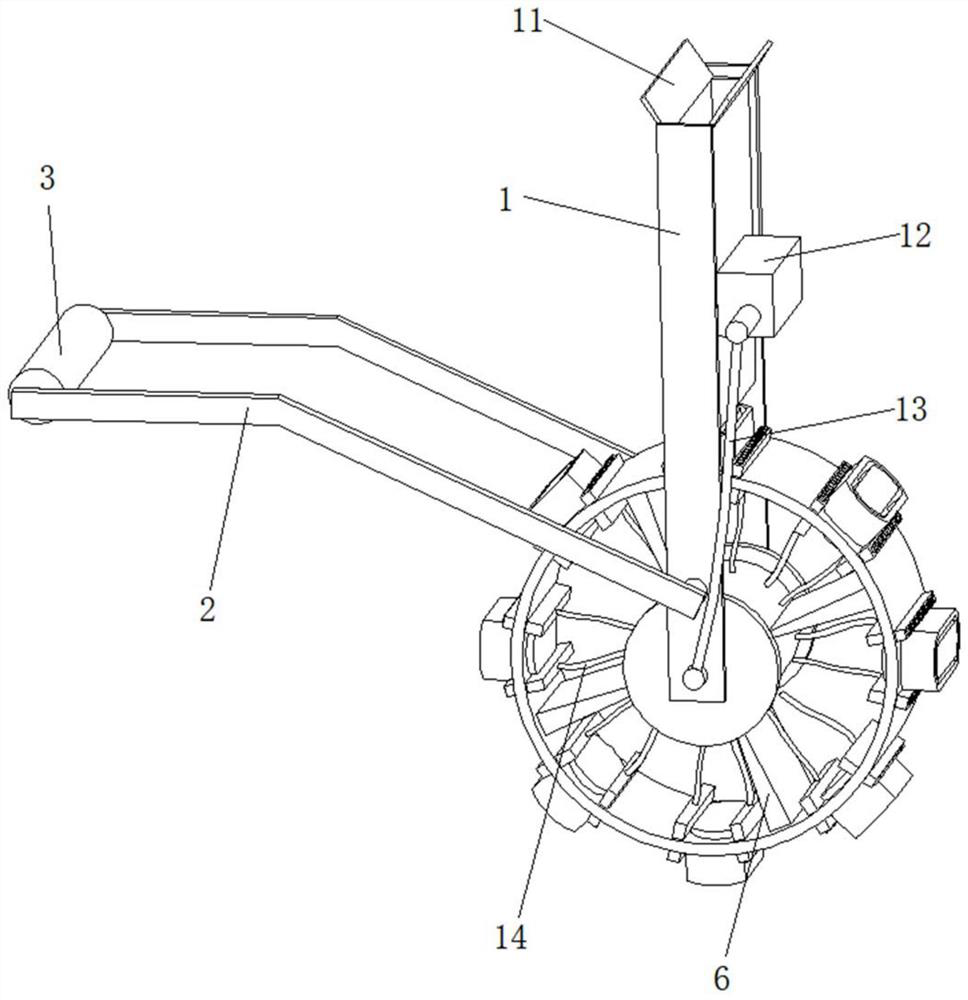

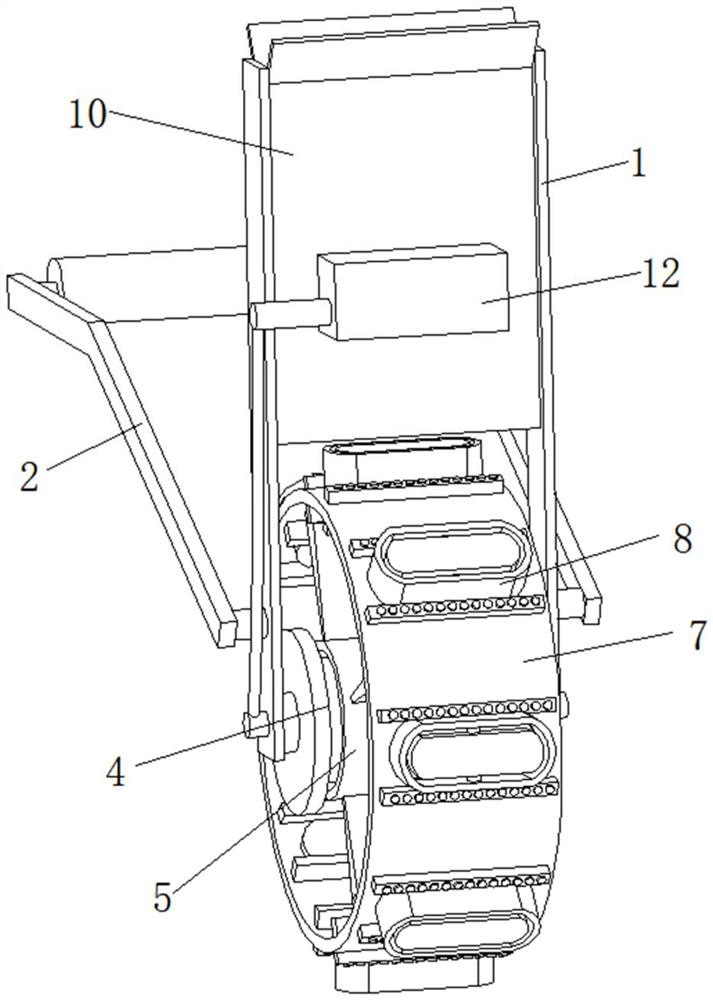

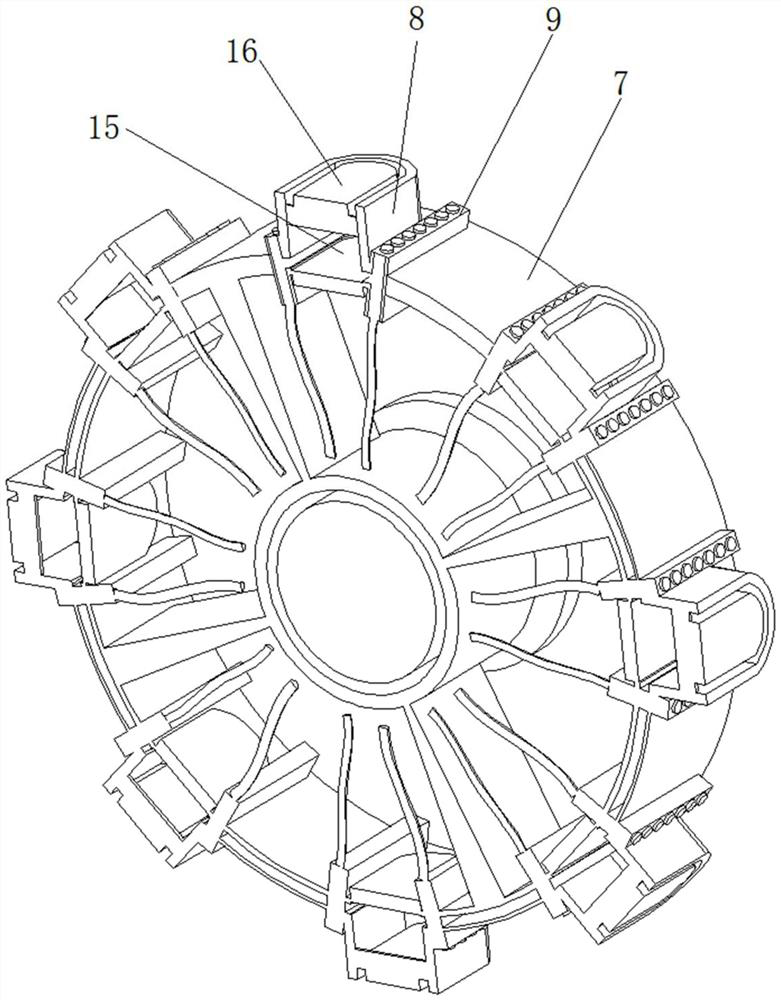

[0033] Such as Figure 1-3As shown, the present invention provides a technical solution: a hand-held seeder for simulating manual sowing of vegetables, including a supporting side frame 1, and a transmission pull rod 2 is rotatably connected to the outside of the support side frame 1 and a position close to the bottom, and the transmission pull rod 2 The end far away from the supporting side frame 1 is fixedly connected with the hand lever 3, the inner side of the supporting side frame 1 and the position close to the bottom is fixedly connected with the counterweight shaft 4, and the middle position outside the counterweight shaft 4 is sheathed and rotatably connected There is a support bearing 5, the outer surface of the support bearing 5 is uniformly fixedly connected with a limiting strut 6, the outer end of the limiting strut 6 is fixedly connected with an outer support roller 7, and the outer surface of the outer support roller 7 is uniformly and fixedly connected at equal...

Embodiment 2

[0037] Such as Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a hand-held seeder for simulating manual sowing of vegetable seeds, and a quantitative storage bin 15 is provided at the middle position of the internal measurement of the sowing pressure groove frame 8, and quantitatively The intermediate position inside the storage bin 15 is rotatably connected with a spring baffle 16 . The range of seed growth is limited, and workers are simulated to manually sow quantitatively, which is convenient for the care work in the process of vegetable seed production.

[0038] The position near the bottom of the support side frame 1 is rotatably connected with a spring shaft 17, and the left side of the spring shaft 17 is fixedly connected with a quantitative material retaining plate 18, and the quantitative material retaining plate 18 is correspondingly arranged with the quantitative storage bin 15.

[0039] The right side of sp...

Embodiment 3

[0041] Such as Figure 5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a hand-held seeder for simulating manual sowing of vegetable seeds, and the feeding spray mechanism 9 includes a supporting frame 91, and the supporting frame The top of the inside of 91 is penetrated and slidably connected with an outer delivery nozzle 92, and the inside of the support frame 91 is fixedly connected with a sealing limiter 93 at a position close to the bottom, and the bottom input end of the support frame 91 communicates with the liquid supply nozzle 14. The left input end of the support frame 91 communicates with the quantitative storage bin 15 . The surface of the land is dug by water pressure to provide power for planting and filling the seeds. At the same time, the viscosity of the water can make the seeds float on the land stably, preventing the seeds from moving with the wind after sowing.

[0042] The middle position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com