Mechanical and automatic granular material discharging equipment and discharging method

An automatic discharging, granular technology, applied in chemical instruments and methods, solid separation, sieves, etc., can solve the problems of high labor intensity, low degree of automation, cumbersome operation, etc., and achieve the effect of reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

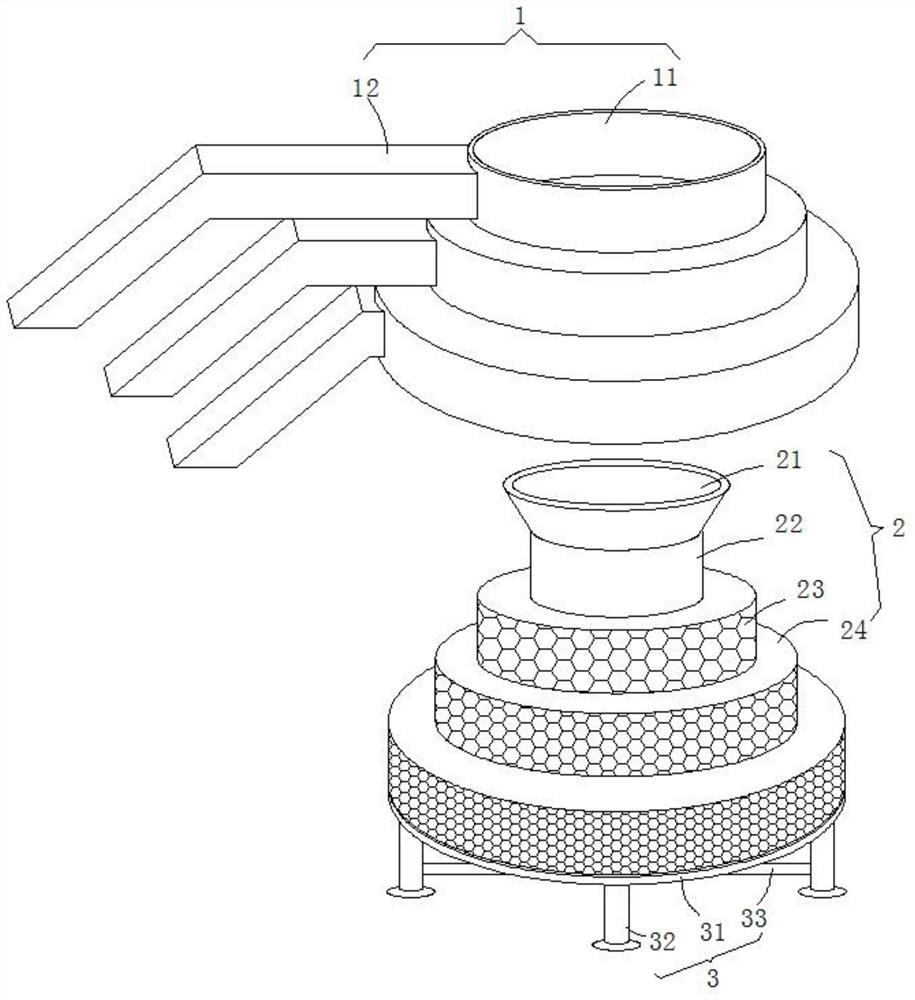

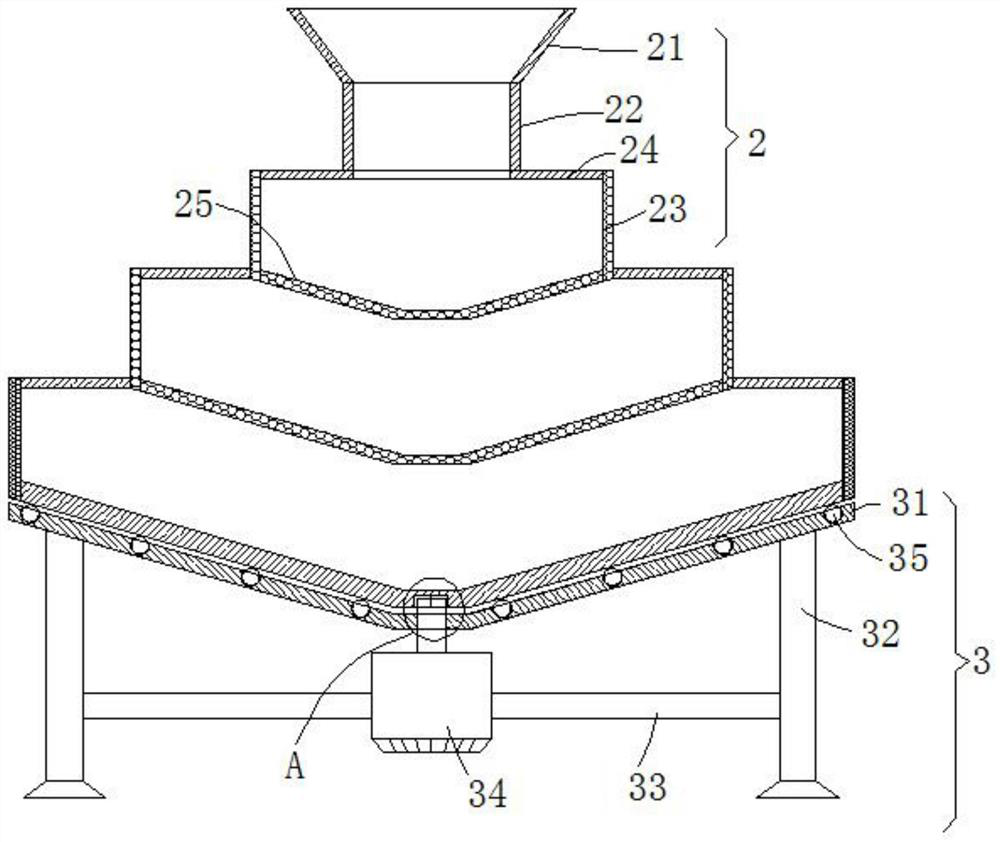

[0025] see Figure 1-3 , the present embodiment provides a mechanical automatic granular material automatic discharge equipment and a discharge method, including a material guide mechanism 1, a screening mechanism 2 and a support mechanism 3, and the support mechanism 3 includes a support plate 31 and a drive motor 34 , the screening material mechanism 2 includes several sieve cylinders 24, and several sieve cylinders 24 are distributed sequentially up and down, and the diameters of several sieve cylinders 24 are increased by 100 mm from top to bottom, and the inner cavity bottom of each sieve cylinder 24 is A loading tray 25 is provided, and the material guide mechanism 1 includes several material guide cylinders 11 and several material guide tubes 12, and several material guide cylinders 11 are distributed up and down in sequence, and the diameters of several material guide cylinders 11 are from top to bottom Increased by 100mm in turn, two adjacent material guide cylinders ...

Embodiment 2

[0034] see Figure 1-3 , further improvements have been made on the basis of Example 1:

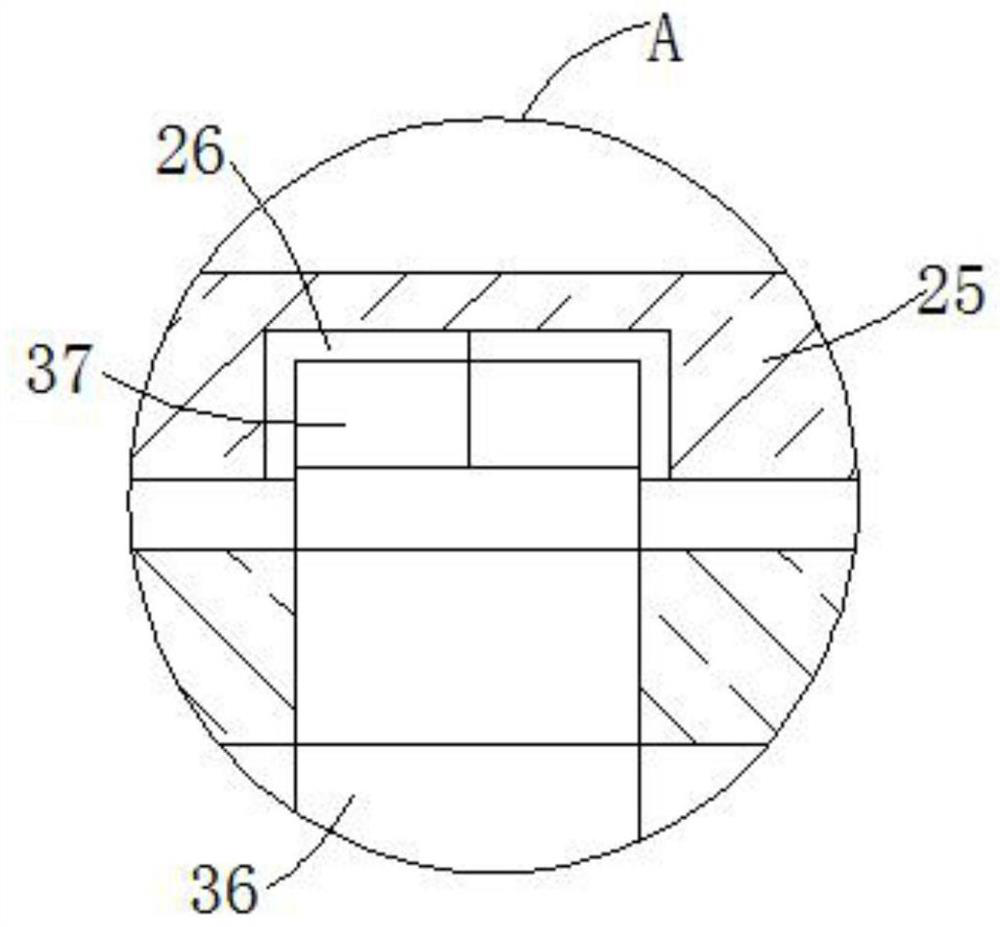

[0035] The top surface of the support plate 31 is embedded with several steel balls 35 that are evenly distributed in a ring and can rotate freely. A plurality of steel balls 35 attached to the bottom surface of the bottom loading tray 25 are rotated to reduce the friction between the support tray 31 and the bottom surface of the bottom loading tray 25 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap