Solid waste crushing treatment processing system

A solid waste and processing system technology, applied in grain processing, solid separation, magnetic separation, etc., can solve the problems of waste of resources, inability to effectively recycle useful waste resources, reduce the utilization rate of solid waste, etc., and improve the utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

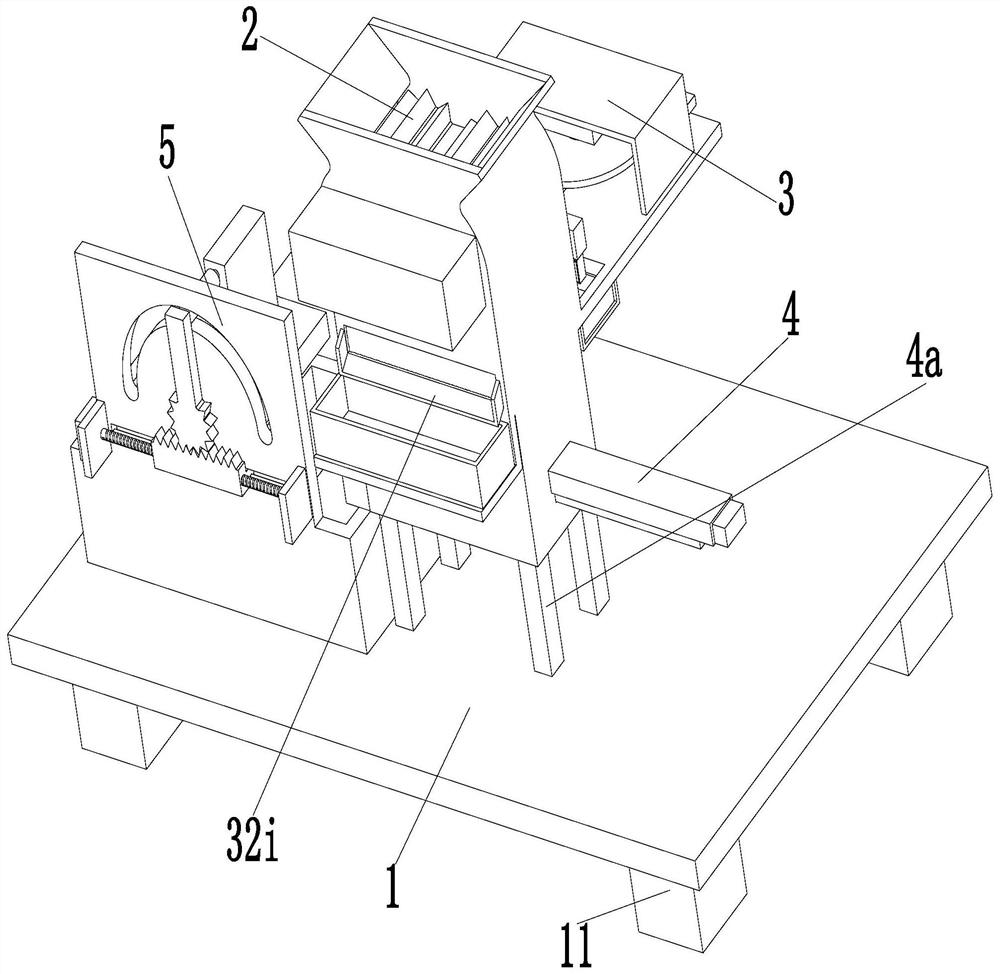

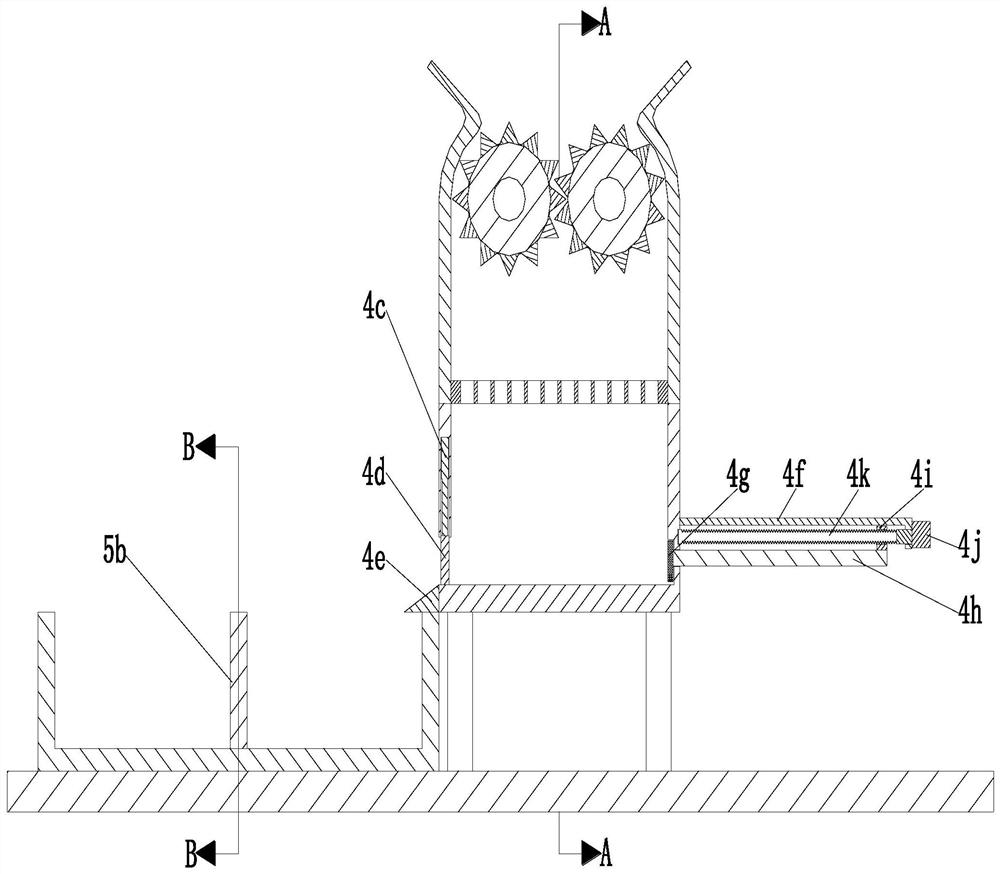

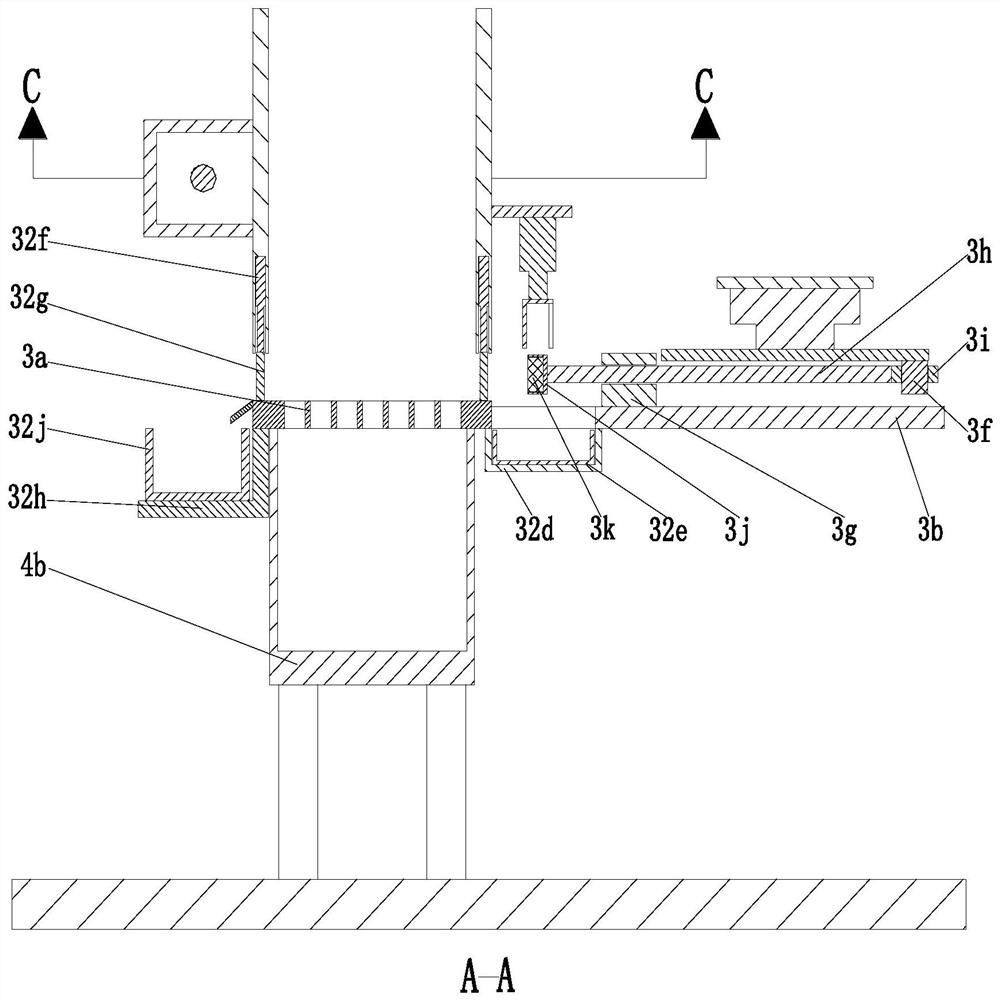

[0028] Such as Figure 1 to Figure 7 As shown, a solid waste crushing and processing system includes a base plate 1, a crushing device 2, a discharge device 3, a propulsion device 4 and a classification device 5. The middle part of the base plate 1 is equipped with a propulsion device 4, and the propulsion device 4 A crushing device 2 is installed on the top, a discharge device 3 is installed on the crushing device 2, and a classification device 5 is installed on the right end of the bottom plate 1.

[0029]The crushing device 2 includes a crushing box 21, a power box 22, a No. 3 motor 23, a connecting rod 24, a power bevel gear 25, a driven bevel gear 26, a rotating rod 27, a crushing roller 28 and a crushing knife 29, A crushing box 21 is install...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap