Plasma melting furnace device based on molten salt heating

A plasma and plasma torch technology, which is applied in the field of plasma melting furnace devices, can solve the problems such as the huge difference between the temperature and the temperature of the upper part of the furnace, and the uneven temperature distribution in the furnace, so as to achieve the effects of improving fluidity and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

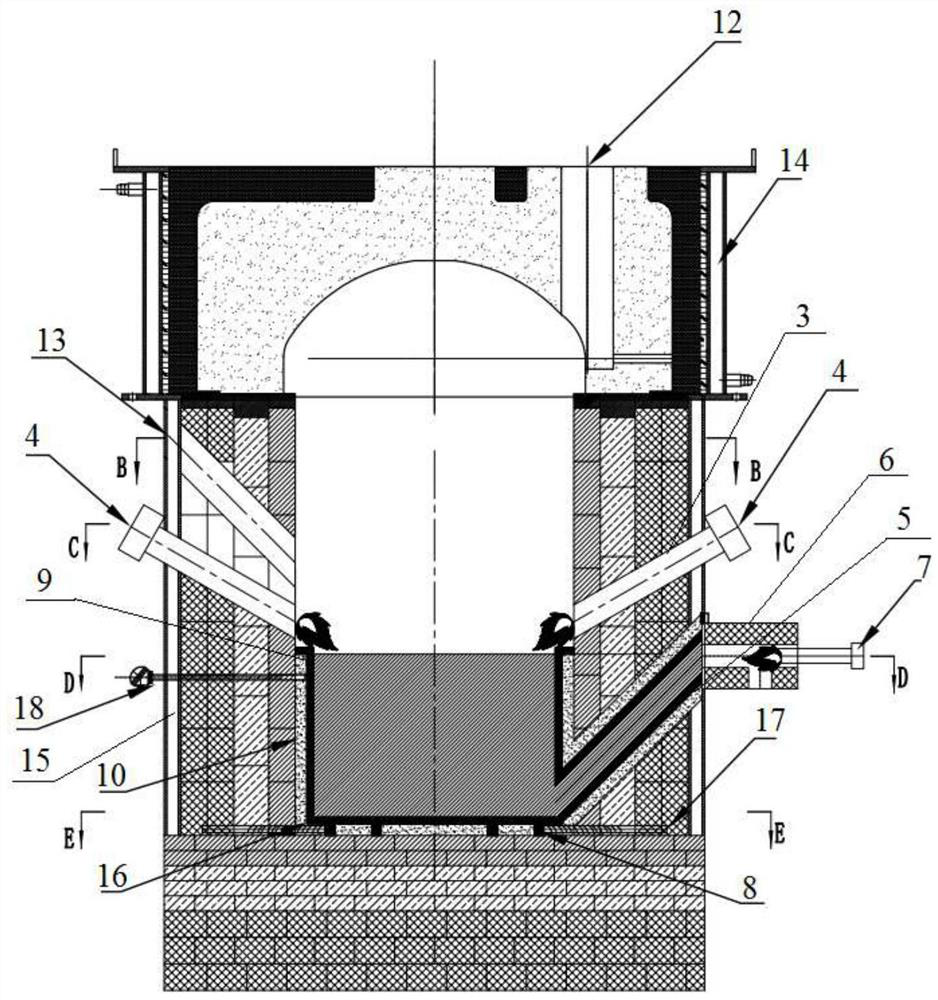

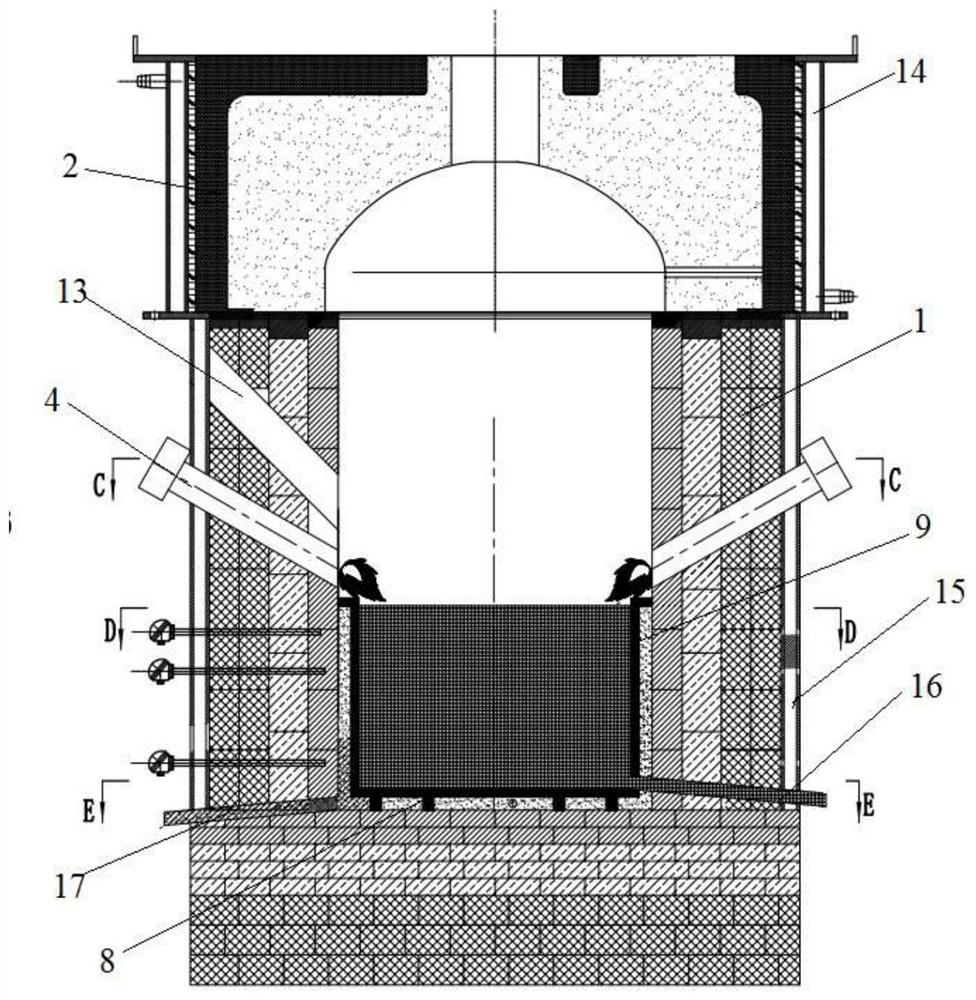

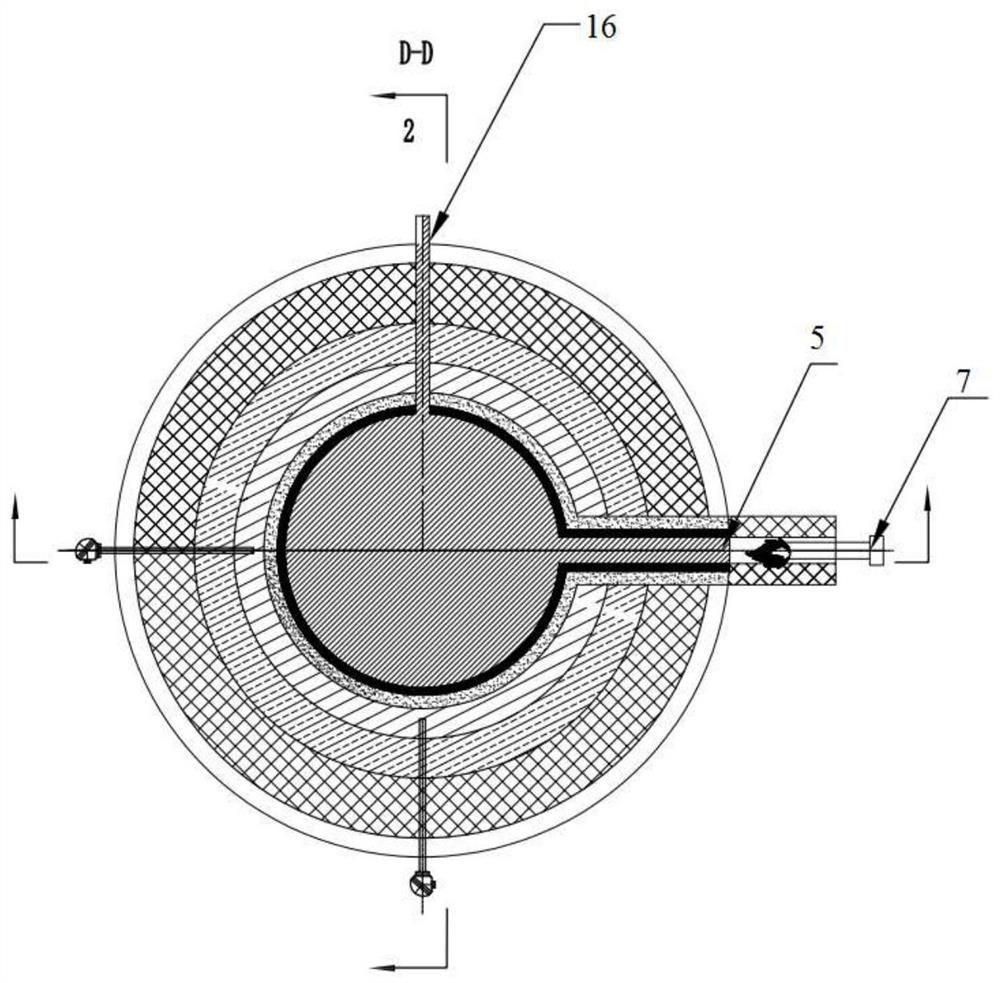

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] A kind of plasma melting furnace device based on molten salt heating of the present invention, such as figure 1 and figure 2 As shown, it includes a furnace body 1, the furnace body 1 is sealed and connected to the furnace cover 2, and the side wall of the furnace body 1 is provided with a plurality of plasma torch channels 3 inclined downward from the outside to the inside, and each plasma torch channel 3 is connected with a plasma torch a4, the side wall of the furnace body 1 is provided with an inclined downward discharge channel 5 from the outside to the inside, and the inner wall of the furnace body 1 and the inner wall of the discharge channel 5 are sealed and connected to the heat conduction layer 9, and the heat conduction layer 9 is connected to the furnace body 1 and the discharge channel 5 The inner wall forms a sealed cav...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap