Elephant trunk type vertical paying-off device

A wire pay-off and elephant trunk technology, applied in the field of the trunk-type vertical wire pay-off, can solve the problems of knotting, slow pay-off, easy strain and deformation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

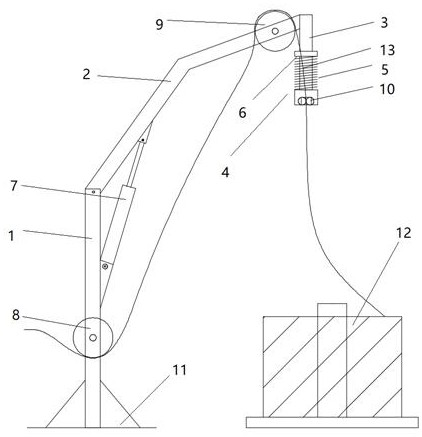

[0018] Embodiment: an elephant trunk type vertical wire payoff, comprising a base, the base is provided with a first support rod; the first support rod is provided with a second support rod; the second support rod is connected with the first The support rod is movably connected; the first support rod is provided with a telescopic rod, and the piston rod of the telescopic rod is movably connected with the second support rod; the end of the second support rod is provided with a third support rod downward; the The end of the third support rod is provided with a wire pulley; the second support rod is provided with a second fixed wire pulley; the first support rod is provided with a first fixed wire pulley; Firstly, it enters the incoming wire wheel, then bypasses above the second fixed wire wheel, then goes down and bypasses under the first fixed wire wheel, and finally enters the processing equipment.

[0019] The elephant trunk type vertical wire payoff in this embodiment is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com