Valve casting molding and cooling technology

A casting molding and process technology, which is applied in casting molding equipment, casting molds, cores, etc., can solve the problems of low valve casting and molding processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0024] Embodiments of the invention are:

[0025] A valve casting molding cooling process, comprising the following steps:

[0026] 1) After the molding sand is dried, it is divided into two parts, namely the first molding sand and the second molding sand;

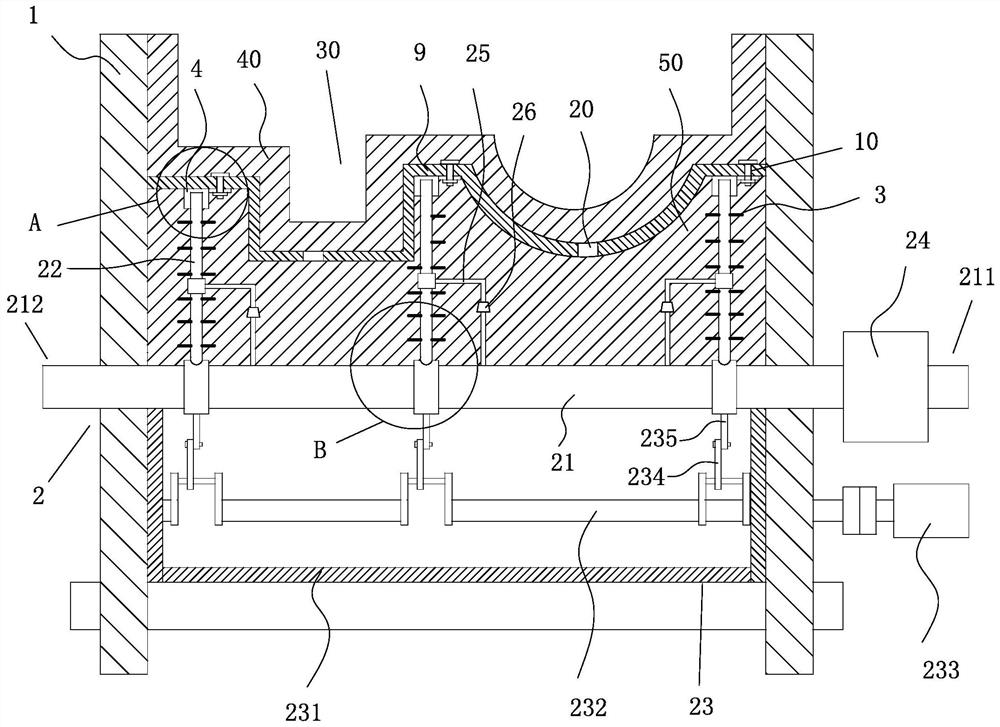

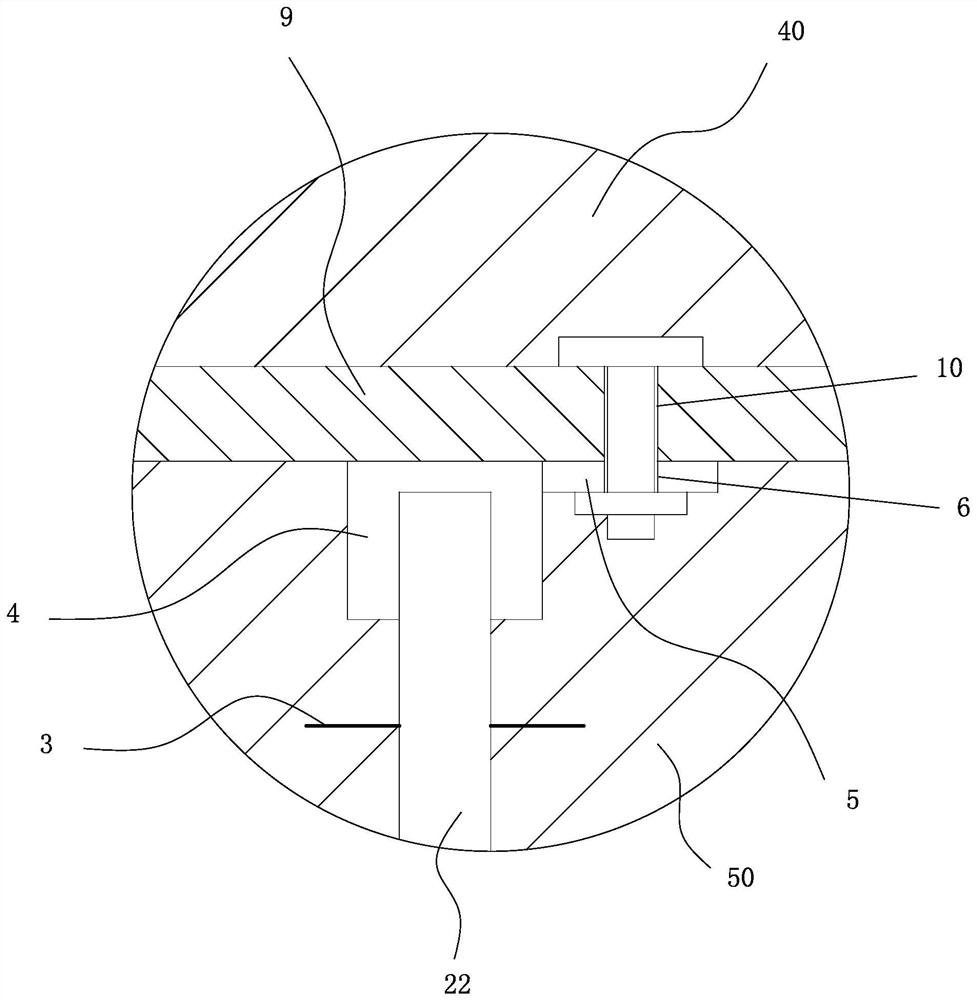

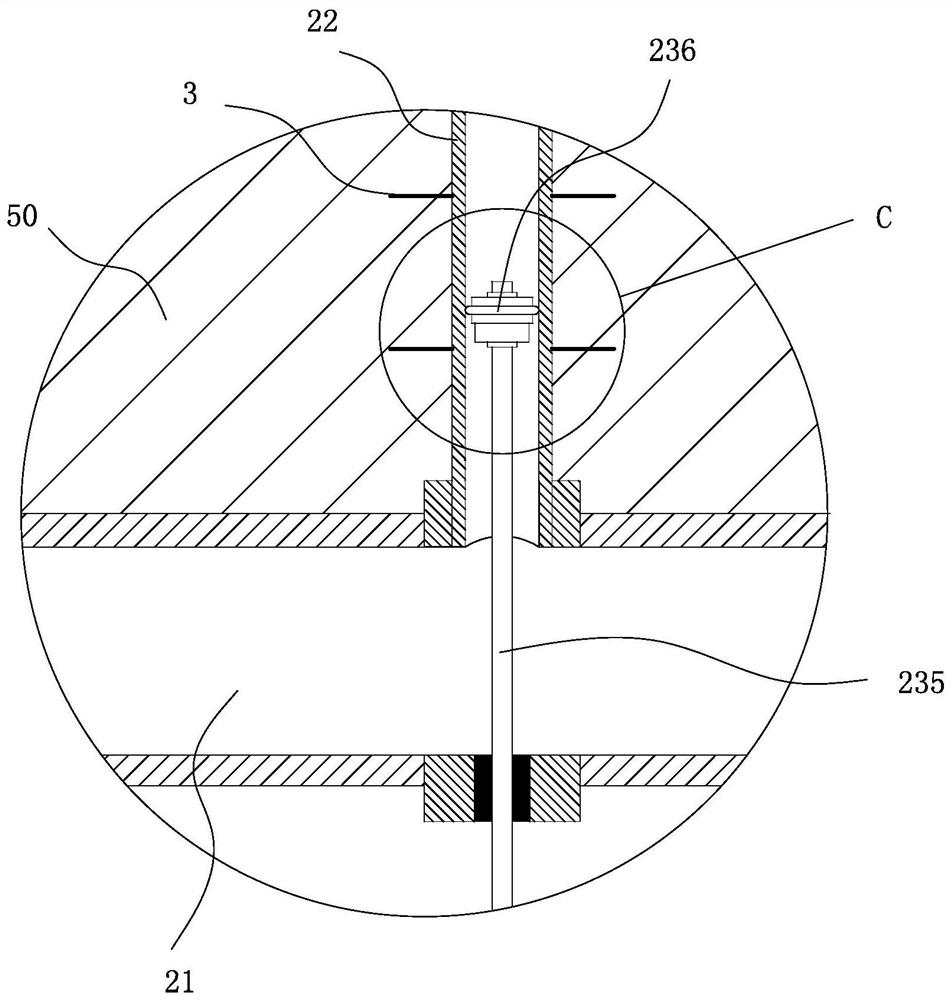

[0027] 2) Fill the first molding sand in the sand mold 1, and embed the cooling device 2 in the sand mold 1, refer to figure 1 , figure 2 , image 3 and Figure 4 As shown, the cooling device 2 includes water guide pipes 21 arranged horizontally, three heat dissipation pipes 22 arranged vertically, and a pumping device 23 that accelerates the flow of cooling water in the heat dissipation pipes 22. Radiating fins 3 are arranged on the outer surface, so as to speed up the heat exchange efficiency of the heat dissipation pipe 22. The heat dissipation pipe 22 is a straight-through pipe fitting,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com