High-strength delayed fracture-resistant hot-rolled steel rail and manufacturing method thereof

A delayed fracture and rail technology, applied in the direction of metal rolling, etc., to achieve the effect of improving impact toughness at room temperature, widely used, and improving the delayed fracture resistance of rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

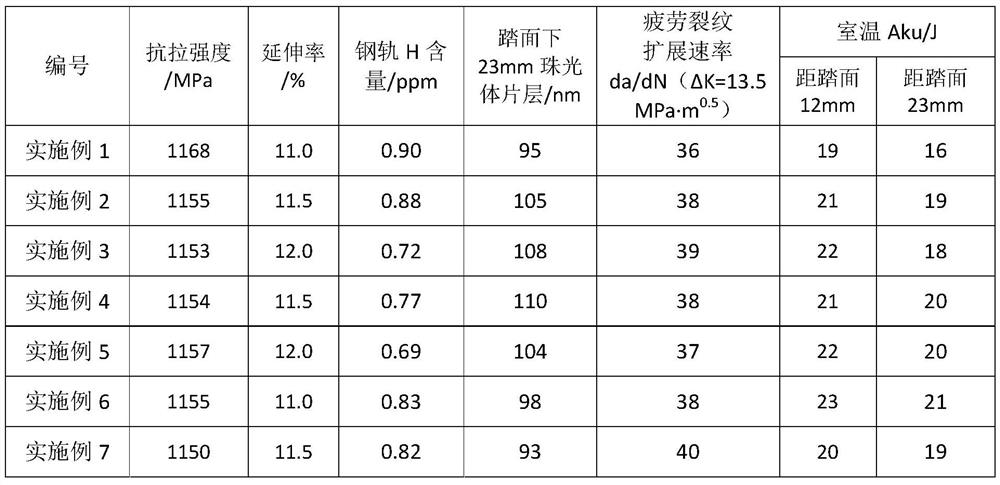

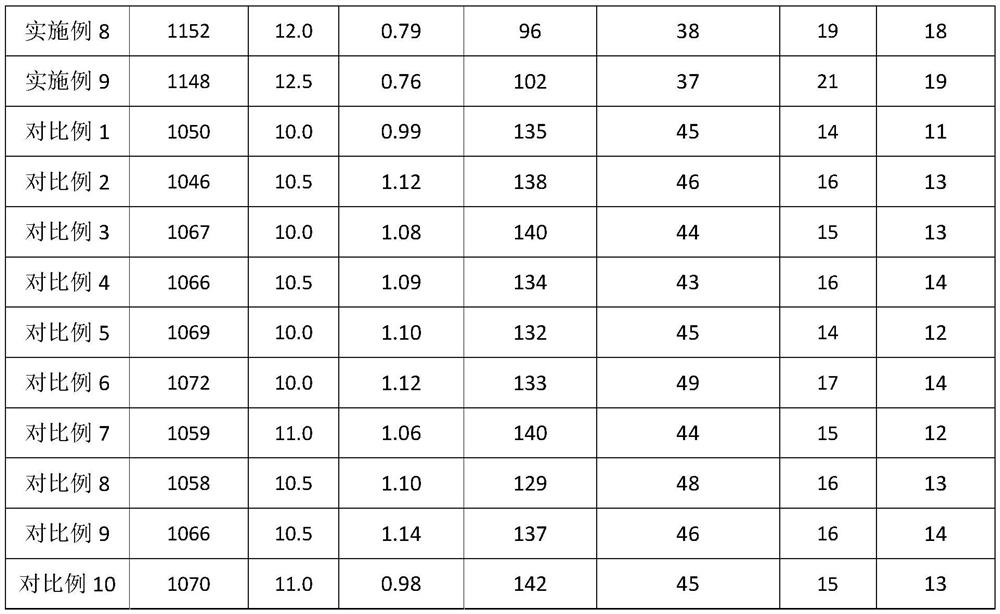

Examples

Embodiment 1

[0068] This example is used to illustrate the specific preparation process of the hot-rolled rail.

[0069]Furnace material is smelted into molten steel through converter smelting or electric furnace smelting, aluminum-free deoxidation, LF refining, RH vacuum treatment or VD vacuum treatment, continuous casting of molten steel into billet, continuous cooling of billet, heating of billet in heating furnace, online rolling into rail, straightening Straightening, flaw detection and processing;

[0070] Wherein, the billet continuous cooling process includes the following steps:

[0071] (1) The first stage of cooling: the steel billet with a surface temperature of 870°C is cooled in the first stage, and the billet is cooled to a surface temperature of 470°C at a cooling rate of 0.6°C / s;

[0072] (2) Second-stage cooling: the steel billet with a surface temperature of 470°C is cooled in the second stage, and the billet is cooled to a surface temperature of 220°C at a cooling rate...

Embodiment 2

[0078] This example is used to illustrate the specific preparation process of the hot-rolled rail.

[0079] Furnace material is smelted into molten steel through converter smelting or electric furnace smelting, aluminum-free deoxidation, LF refining, RH vacuum treatment or VD vacuum treatment, continuous casting of molten steel into billet, continuous cooling of billet, heating of billet in heating furnace, online rolling into rail, straightening Straightening, flaw detection and processing;

[0080] Wherein, the billet continuous cooling process includes the following steps:

[0081] (1) The first stage of cooling: the steel billet with a surface temperature of 850°C is cooled in the first stage, and the billet is cooled to a surface temperature of 450°C at a cooling rate of 0.7°C / s;

[0082] (2) Second-stage cooling: the steel billet with a surface temperature of 450°C is cooled in the second stage, and the billet is cooled to a surface temperature of 200°C at a cooling rat...

Embodiment 3

[0088] This example is used to illustrate the specific preparation process of the hot-rolled rail.

[0089] Furnace material is smelted into molten steel through converter smelting or electric furnace smelting, aluminum-free deoxidation, LF refining, RH vacuum treatment or VD vacuum treatment, continuous casting of molten steel into billet, continuous cooling of billet, heating of billet in heating furnace, online rolling into rail, straightening Straightening, flaw detection and processing;

[0090] Wherein, the billet continuous cooling process includes the following steps:

[0091] (1) The first stage of cooling: the steel billet with a surface temperature of 830°C is cooled in the first stage, and the billet is cooled to a surface temperature of 420°C at a cooling rate of 0.8°C / s;

[0092] (2) Second-stage cooling: the steel billet with a surface temperature of 420°C is cooled in the second stage, and the billet is cooled to a surface temperature of 180°C at a cooling rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com