Electric welding device for building construction

A technology for construction and electric welding machines, which is applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of inconvenient crossing of obstacles by moving seats, lack of shock absorption mechanism of electric welding machines, and shortening the service life of electric welding machines, etc. Obstacles, good shock absorption, prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

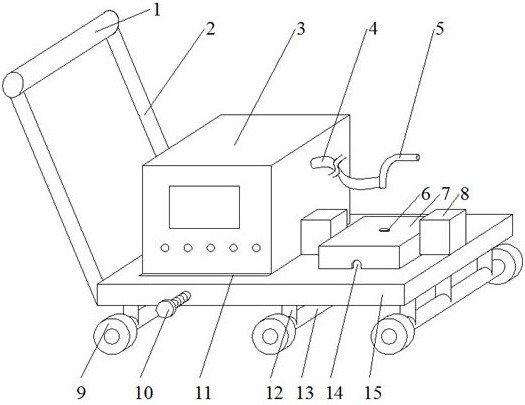

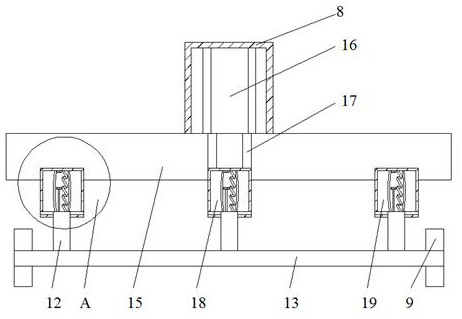

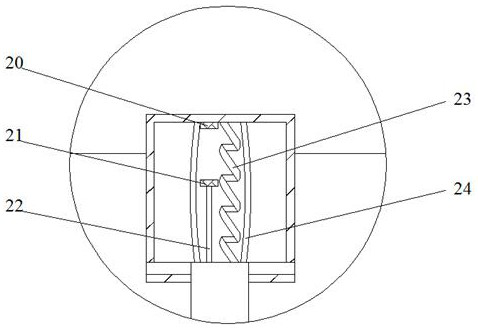

[0027] refer to Figure 1-4 , an electric welding device for building construction, comprising a moving seat 15 and an electric welding machine 3, the centers of both sides of the center line of the top of the moving seat 15 are equipped with a motor box 8, and the electric box 8 protects the hydraulic telescopic rod 16, and the moving seat 15 The top is located in the middle of two of the motor boxes 8, and a limiting groove 25 is provided, and a fixing mechanism for fixing the electric welding machine 3 is arranged in the limiting groove 25. The top of the moving seat 15 is located in the middle of the other two motor boxes 8, and a filter glass cover 7 is installed. The top center of the filter glass cover 7 is provided with a welding hole 6, and the bottoms of opposite sides of the filter glass cover 7 are provided with fixing holes 14, and the bottom of the moving seat 15 is located at the bottom of each motor box 8 and is provided with a cross bar. 13. The motor box 8 is...

Embodiment 2

[0031] refer to Figure 5 The only difference between this embodiment and Embodiment 1 is that the fixing mechanism includes a moving rod 26, and the fixed plate 11 is slidably connected to one side inside the limiting groove 25, and the moving rod 26 runs through the side of the moving seat 15 and extends into the limiting groove 25. , the moving rod 26 is slidably connected to the moving seat 15, and the moving rod 26 and the moving seat 15 are fixed by locking bolts 27.

[0032] The working principle of this embodiment: place the electric welding machine 3 inside the limit slot 15, push the moving rod 26 to drive the fixed plate 11 to move forward and tightly against the electric welding machine 3, and then tighten the locking bolt 27 to fix the position of the moving rod 26 , so that the electric welding machine 3 is fixed above the mobile seat 15, and electric welding machines 3 of different sizes can be fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com