Subway vehicle built-in top plate and air duct integrated module structure

An integrated module, in-vehicle technology, used in railway roofs, railway vehicle heating/cooling, railway car body components, etc., can solve problems such as the inability of sealing to meet the requirements, the difficulty of further reducing the weight of the interior roof and air ducts, and the lack of assembly accuracy. , to solve the problem of insufficient fresh air volume, achieve lightweight design, and reduce installation procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

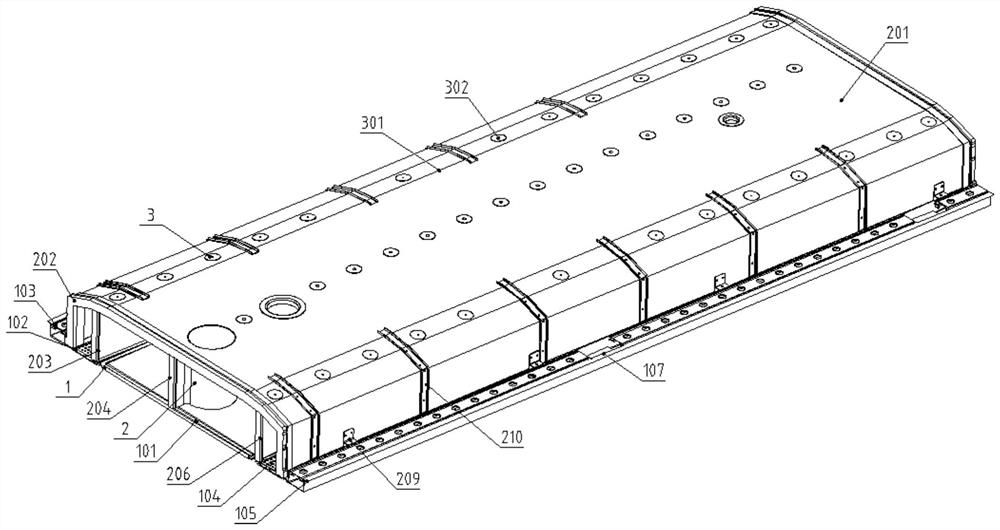

[0029] refer to figure 1 , the specific embodiment of the present invention is a subway vehicle interior roof and air duct integrated module structure, including the interior roof structure 1, air duct structure 2, thermal insulation layer 3, the upper side of the interior roof structure 1 and the air duct structure The lower side of 2 is bonded and connected by angle iron bolts, and the thermal insulation layer 3 is fixed on the upper surface of the air duct structure 2 by bonding.

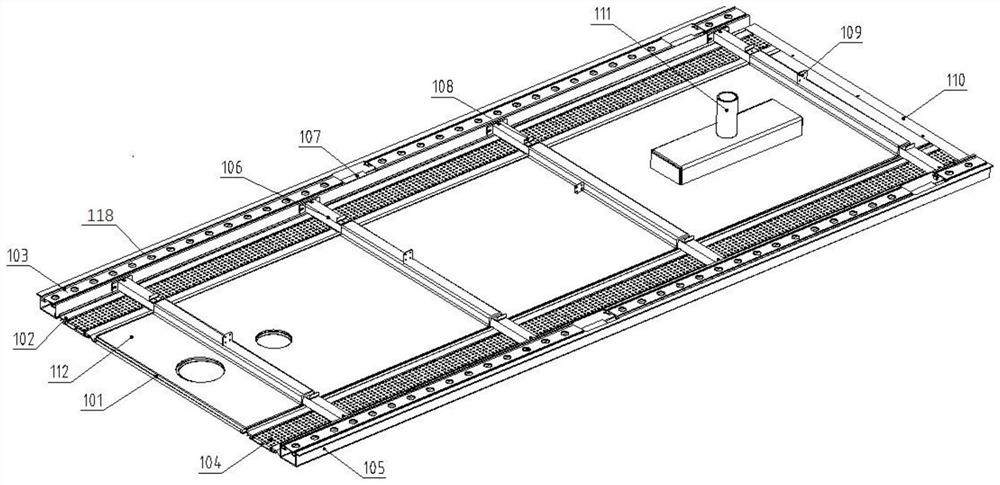

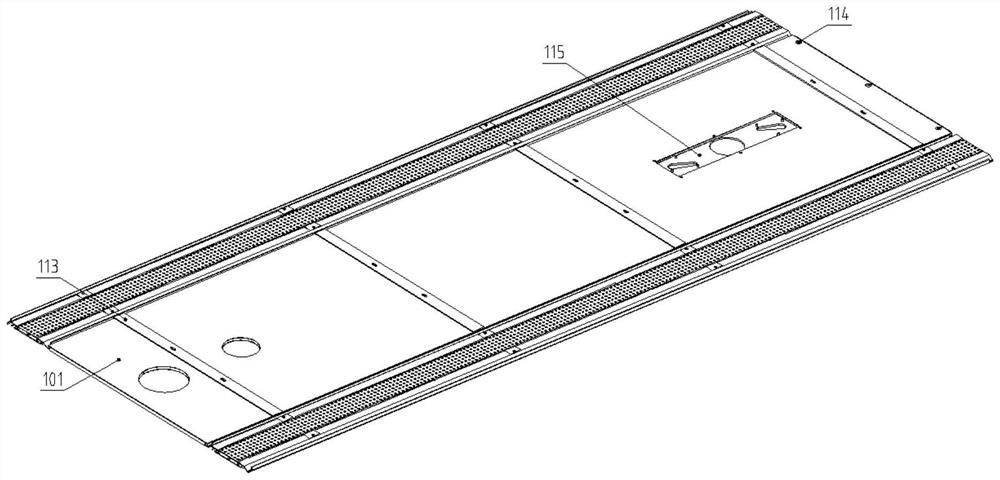

[0030] according to Figures 2 to 4 As shown, the built-in roof structure includes paper honeycomb roof 101, roof grid 102, roof profile 1 103, ventilation plate 104, roof profile 2 105, roof main beam 106, handrail installation chute 107, and air duct partition plate angle iron 1 108 , Angle iron 2 of air duct partition plate 109, seam retaining strip 110, smoke probe and camera integrated module shell 111, air duct bottom plate 112, shock absorbing pad 113, glue filling screw sleeve 114, smoke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com