Assembly type floor facing integrated plate convenient for paving floor heating

A prefabricated floor panel technology, which is applied to floors, heating methods, lighting and heating equipment, etc., can solve the problems that floor panels are easily damaged by collision, cumbersome laying work, and affect the efficiency of floor heating construction, so as to improve the construction efficiency of floor heating, Effect of avoiding collision damage and simplifying laying work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

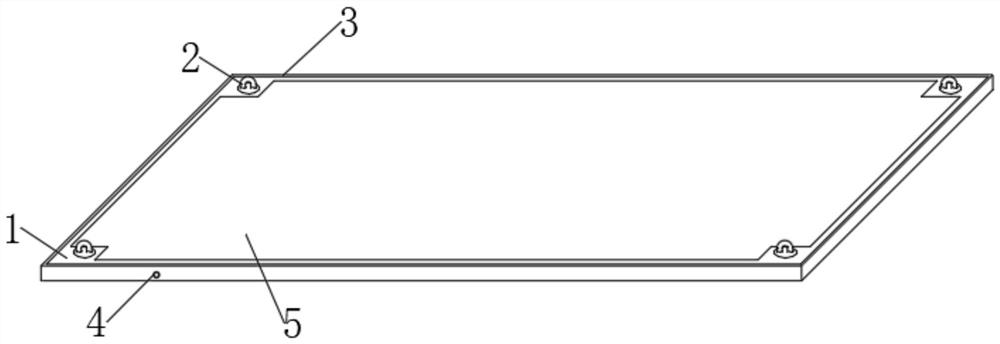

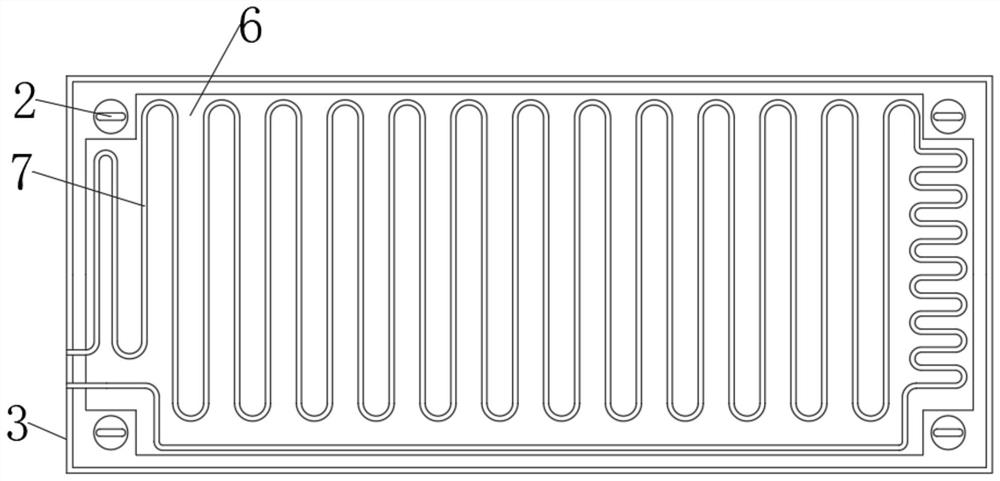

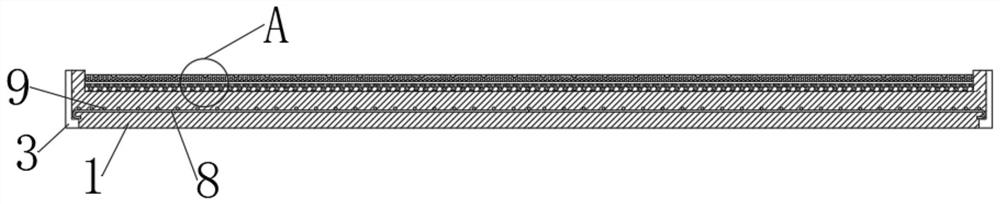

[0030] Such as Figure 1-Figure 5 As shown in the figure, a prefabricated floor facing integrated panel that is convenient for laying floor heating includes a floor panel 1, a protective frame 3 and a protective adhesive tape 5, the four sides of the floor panel 1 are provided with a protective frame 3, and the upper side of the floor panel 1 is glued. There is a protective tape 5, the uppermost side of the floor board 1 is provided with a thermal insulation layer 6, the upper side of the thermal insulation layer 6 is integrally formed with a pipe groove 7, and the lower side of the thermal insulation layer 6 is provided with an aluminum foil thermal insulation layer 11, and the aluminum foil thermal insulation layer 11 The lower side is provided with leveling layer 10, thermal insulation layer 6, aluminum foil insulation layer 11, leveling layer 10 and protective adhesive tape 5, so that when the assembled floor board is in use, the floor heating laying work does not need to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com