Capacitive vibration sensor and power plant fan diagnosis system and method

A vibration sensor and capacitive technology, applied in the direction of engines, wind turbines, machines/engines, etc., can solve the problems of reduced fan performance, hazards to human health and working environment, damage to blades and air ducts, etc., to achieve strong computing power, monitoring The effect of good effect and great application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

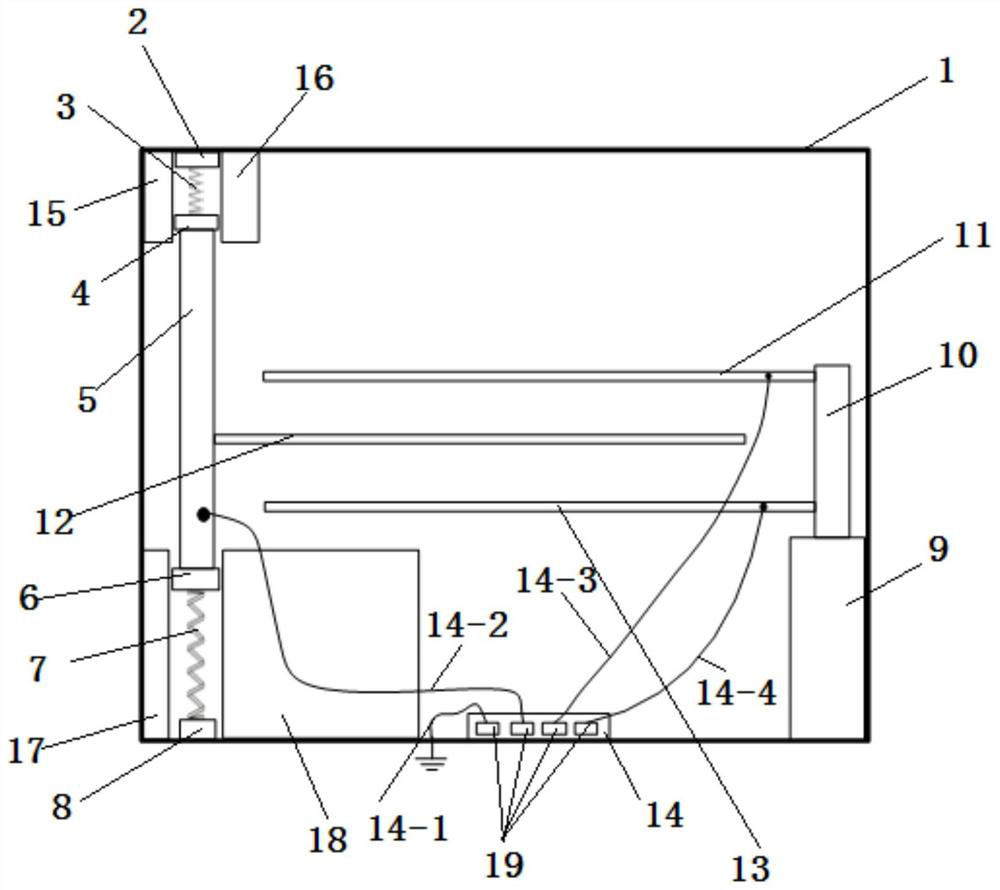

[0054] A kind of capacitive vibration sensor of the present invention, as figure 1 As shown, a housing 1 is included, and a first insulating gasket 2, an upper spring 3, a second insulating gasket 4, and a first conductive rod 5 are sequentially connected between the top plate and the bottom plate of the housing 1 from top to bottom. , the third insulating spacer 6, the lower spring 7 and the fourth insulating spacer 8, the bottom plate in the housing 1 is also provided with a resin pillar 9, the top of the resin pillar 9 is provided with a second conductive rod 10, the first conductive rod 5 Parallel to the second conductive rod 10, there are three capacitor plates parallel to each other between the first conductive rod 5 and the second conductive rod 10, which are: capacitor plate A11, capacitor plate B12 from top to bottom and the capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com