Highway engineering supervision quality inspection equipment

A quality inspection and engineering technology, applied in the field of road engineering supervision quality inspection equipment, can solve the problems of not having the ability to check the friction coefficient level of roads, and the inability to measure road slopes, etc., to achieve reliable connection, convenient inspection and maintenance, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

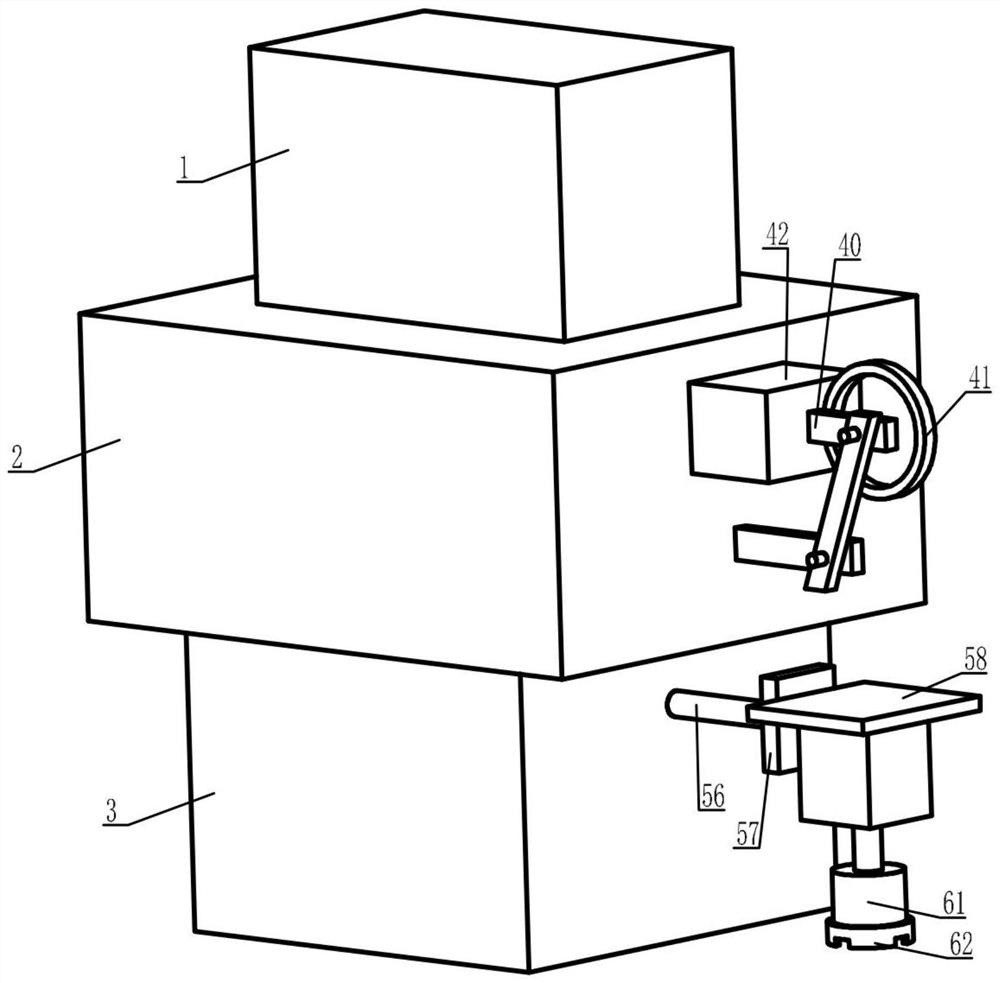

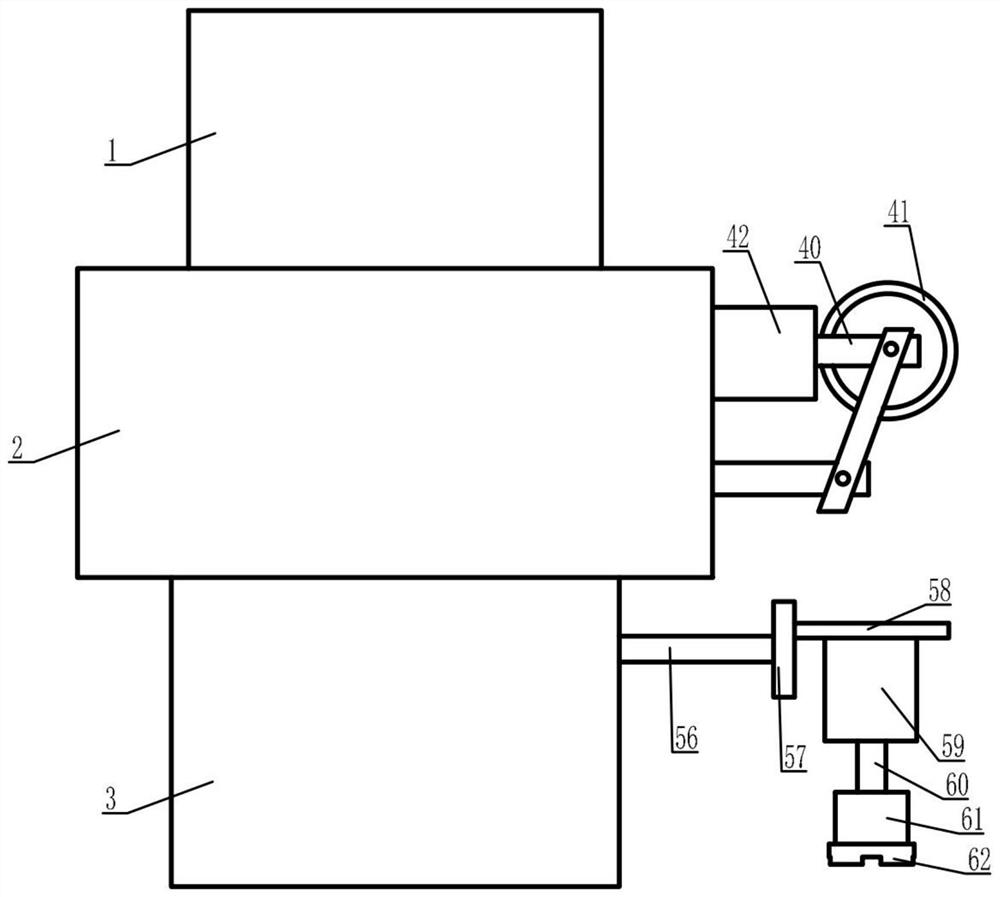

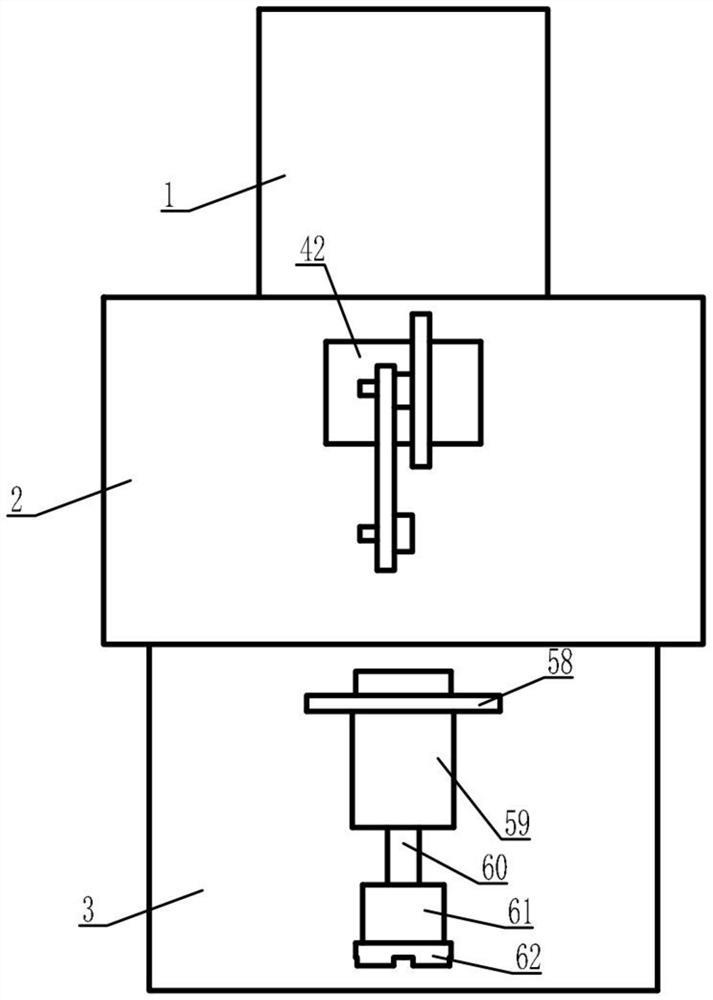

[0029] refer to Figure 1 to Figure 9 A kind of highway engineering supervision quality inspection equipment provided by the present invention includes a friction inspection box 1, the bottom of the friction inspection box 1 is provided with a measurement box 2, and the bottom of the measurement box 2 is provided with a sampling box 3, so The inner right surface of the friction test box 1 described above is sequentially fixed with a first horizontal plate 13, a second horizontal plate 14, a third horizontal plate 15, and a fourth horizontal plate 16. The first horizontal plate 13, The left lower surface of the second horizontal plate 14 and the third horizontal plate 15 are respectively fixed with a first stop block 17, a second stop block 18, and a third stop block 19. The right ends of the two stoppers 18 and the third stopper 19 are respectively in contact with the left su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com