Electric power inspection time prediction method, device and system

A technology for time prediction and power inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

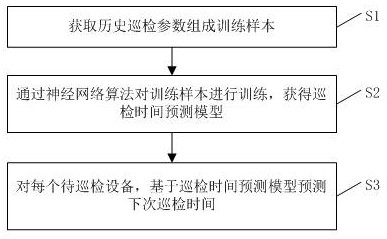

[0034] Such as figure 1 As shown, this embodiment provides a method for predicting power inspection time, including the following steps:

[0035] S1, obtaining historical inspection parameters to form training samples;

[0036] S2, train the training samples through the neural network algorithm, and obtain the inspection time prediction model;

[0037] S3. For each device to be inspected, predict the next inspection time based on the inspection time prediction model.

[0038] Based on a large number of historical inspection parameters, the method establishes an inspection time prediction model through a neural network algorithm, and predicts the inspection time of each equipment to be inspected through the inspection time prediction model. Inspection parameters, the predicted inspection time is more accurate and reliable.

[0039] Substation is an equipment that usually needs to be inspected in the power field, and its failure probability is related to many factors. In thi...

Embodiment 2

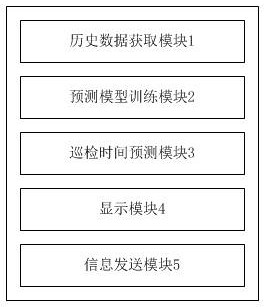

[0044] Such as figure 2 As shown, on the basis of the first embodiment, this embodiment provides a power inspection time prediction device, including the following functional modules.

[0045] Historical data acquisition module 1: Obtain historical inspection parameters and form training samples;

[0046] Prediction model training module 2: train the training samples through the neural network algorithm to obtain the inspection time prediction model;

[0047] Inspection time prediction module 3: For each device to be inspected, predict the next inspection time based on the inspection time prediction model.

[0048] Among them, the acquisition inspection parameters shown in the historical data acquisition module 1 include power consumption of the jurisdiction area supplied by the electric equipment, ambient temperature, ambient humidity, service time of the electric equipment, and time interval between two corresponding failures. The input parameters of the neural network al...

Embodiment 3

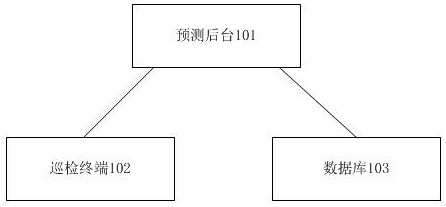

[0052] Such as image 3 As shown, on the basis of Embodiment 1 and Embodiment 2, this embodiment provides a power inspection time prediction system, including a prediction background 101 , an inspection terminal 102 , and a database 103 . Wherein, the prediction background 101 communicates with the inspection terminal 102 and the database 103 respectively.

[0053] The forecasting background 101 is configured with the device described in Embodiment 2, and the database 103 stores the geographical location and inspection specifications of each device to be inspected. The inspection terminal 102 receives and displays the reminder information sent by the forecasting background.

[0054] The prediction background 101 predicts the inspection time of each equipment to be inspected according to the configured device, and when any equipment to be inspected is about to arrive at the inspection time, it obtains the geographical location and inspection specifications of the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com