A high-precision 3D printer with a camera

A 3D printer, high-precision technology, applied in the direction of mechanical equipment, coating devices, processing drive devices, etc., can solve the problems of increasing production costs, affecting printing quality, not taking into account the synchronization of printing heads, etc., to achieve the elimination of fit clearance, Effect of increasing adjustability, saving production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the examples, but the present invention is not limited in any way, and any transformation or substitution made based on the teaching of the present invention belongs to the protection scope of the present invention.

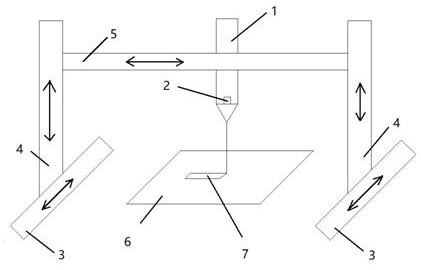

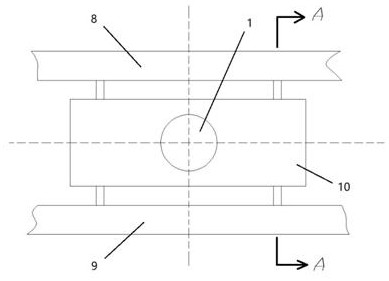

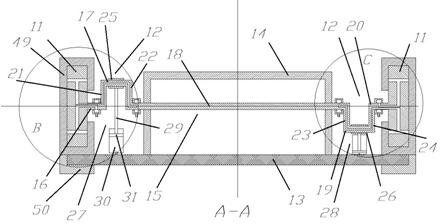

[0035] Such as figure 1 As shown, the high-precision 3D printer with a camera of the present invention includes: a print head 1, a camera 2, a lateral guide seat 3, a vertical guide column 4, a horizontal guide rod 5 and a printing platform 6, and the camera 2 is fixedly arranged on the print head 1 above, it is used to collect the image data of the three-dimensional printing part 7, and stop printing by the printing head 1 after it is judged that the printing of the three-dimensional printing part 7 is completed. The print head 1 is slidably arranged on the horizontal guide rod 5 through the sliding seat 10, and can slide left and right along the horizontal guide rod 5. A vertical g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com