High-temperature-resistant degradable temporary plugging liquid and preparation method thereof

A technology of temporary plugging fluid and high temperature resistance, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as application limitations, poor temperature resistance of chemical temporary plugging agents, and inability to use mechanical layered acidification, etc. The liquid is uniform, the construction risk is small, and the suspension ability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

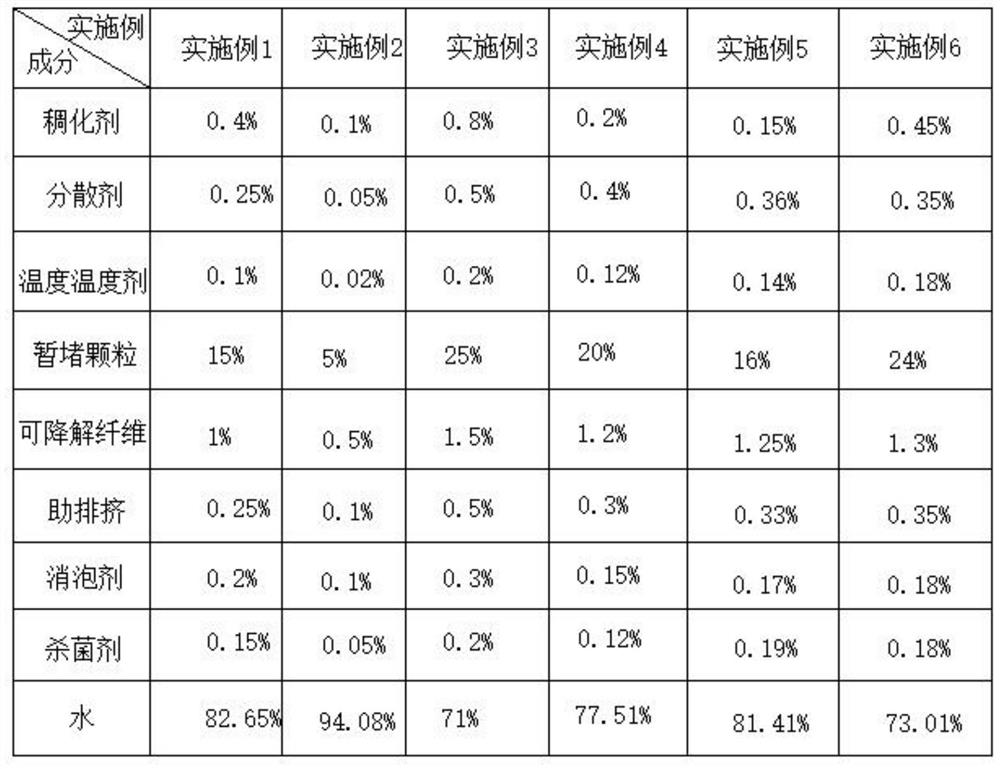

[0027] Such as figure 1 As shown, the temporary plugging fluid includes at least the following components and each component is composed of the following percentages: thickener 0.4%, dispersant 0.25%, temperature stabilizer 0.1%, temporary plugging particles 15%, degradable fiber 1% , 0.25% drainage aid, 0.2% defoamer, 0.15% fungicide, 82.65% water.

[0028] A preparation method of a high-temperature-resistant and degradable temporary plugging fluid, comprising the steps above:

[0029] a1. At room temperature, add the formulated amount of thickener to the water, stir evenly, and the stirring speed is 60-200 revolutions per minute. After the thickener is completely swollen, add the formulated amount of dispersant, defoamer, temperature Stabilizer, drainage aid, stir evenly to obtain base liquid;

[0030] a2. Add the formula amount of degradable fiber into the base liquid, after stirring evenly, the stirring speed is 60-200 revolutions per minute, add the formula amount of te...

Embodiment 2

[0044] Such as figure 1 As shown, the temporary plugging fluid includes at least the following components and each component is composed of the following percentages: thickener 0.1%, dispersant 0.05%, temperature stabilizer 0.02%, temporary plugging particles 5%, degradable fiber 0.5% , drainage aid 0.1%, defoamer 0.1%, fungicide 0.05%, water 94.08%.

[0045] Its proportioning method is identical with embodiment 1.

Embodiment 3

[0047] Such as figure 1 As shown, the temporary plugging fluid includes at least the following components and each component is composed of the following percentages: thickener 0.8%, dispersant 0.5%, temperature stabilizer 0.2%, temporary plugging particles 25%, degradable fiber 1.5% , 0.5% drainage aid, 0.3% defoamer, 0.2% fungicide, 71% water.

[0048] Its proportioning method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com