Fabric preparation process

A preparation process and fabric technology, applied in the processing of textile materials, liquid/gas/steam textile material processing, textiles, etc., can solve the problems of inability to achieve insect repellent and anti-mosquito, achieve superior quality, improve resistance, and applicability wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

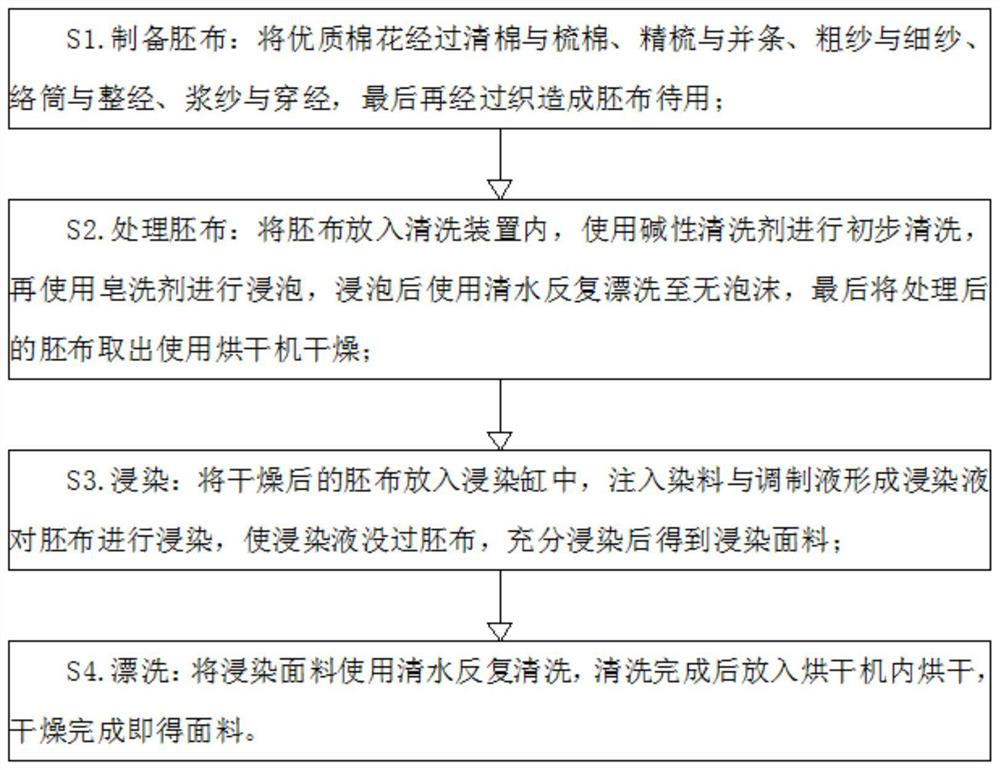

[0030] A fabric preparation process, comprising the following steps:

[0031] S1. Preparation of greige cloth: the high-quality cotton is cleaned and carded, combed and drawn, roving and spun yarn, winding and warping, sizing and drawing in, and finally weaved into greige cloth for use;

[0032] S2. Treatment of gray cloth: Put the gray cloth into the cleaning device, use alkaline cleaning agent for preliminary cleaning, then use soaping agent to soak, after soaking, use clean water to rinse repeatedly until there is no foam, and finally take out the treated gray cloth Use a dryer to dry;

[0033] S3. Dip dyeing: put the dried gray cloth into a dip dyeing vat, inject dye and preparation solution to form a liquid to dip the gray cloth, make the liquid soak the gray cloth, and obtain a dip-dyed fabric after fully dipping;

[0034] S4. Rinsing: Wash the dip-dyed fabric repeatedly with clean water, put it in the dryer to dry after washing, and get the fabric after drying.

[003...

Embodiment 2

[0051] A fabric preparation process, comprising the following steps:

[0052] S1. Preparation of greige cloth: the high-quality cotton is cleaned and carded, combed and drawn, roving and spun yarn, winding and warping, sizing and drawing in, and finally weaved into greige cloth for use;

[0053] S2. Treatment of gray cloth: Put the gray cloth into the cleaning device, use alkaline cleaning agent for preliminary cleaning, then use soaping agent to soak, after soaking, use clean water to rinse repeatedly until there is no foam, and finally take out the treated gray cloth Use a dryer to dry;

[0054] S3. Dip dyeing: put the dried gray cloth into a dip dyeing vat, inject dye and preparation solution to form a liquid to dip the gray cloth, make the liquid soak the gray cloth, and obtain a dip-dyed fabric after fully dipping;

[0055] S4. Rinsing: Wash the dip-dyed fabric repeatedly with clean water, put it in the dryer to dry after washing, and get the fabric after drying.

[005...

Embodiment 3

[0072] A fabric preparation process, comprising the following steps:

[0073] S1. Preparation of greige cloth: the high-quality cotton is cleaned and carded, combed and drawn, roving and spun yarn, winding and warping, sizing and drawing in, and finally weaved into greige cloth for use;

[0074] S2. Treatment of gray cloth: Put the gray cloth into the cleaning device, use alkaline cleaning agent for preliminary cleaning, then use soaping agent to soak, after soaking, use clean water to rinse repeatedly until there is no foam, and finally take out the treated gray cloth Use a dryer to dry;

[0075] S3. Dip dyeing: put the dried gray cloth into a dip dyeing vat, inject dye and preparation solution to form a liquid to dip the gray cloth, make the liquid soak the gray cloth, and obtain a dip-dyed fabric after fully dipping;

[0076] S4. Rinsing: Wash the dip-dyed fabric repeatedly with clean water, put it in the dryer to dry after washing, and get the fabric after drying.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com