Automatic sewing equipment for automobile seat cover

A car seat and sewing technology, which is applied in the direction of sewing machines, sewing equipment, sewing machine components, etc., can solve the problems of lower quality of cover products, affecting the quality of vehicle interior decoration, and irregular sewing lines, etc., and achieve a compact layout structure , Reduce manufacturing costs and risk of errors, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

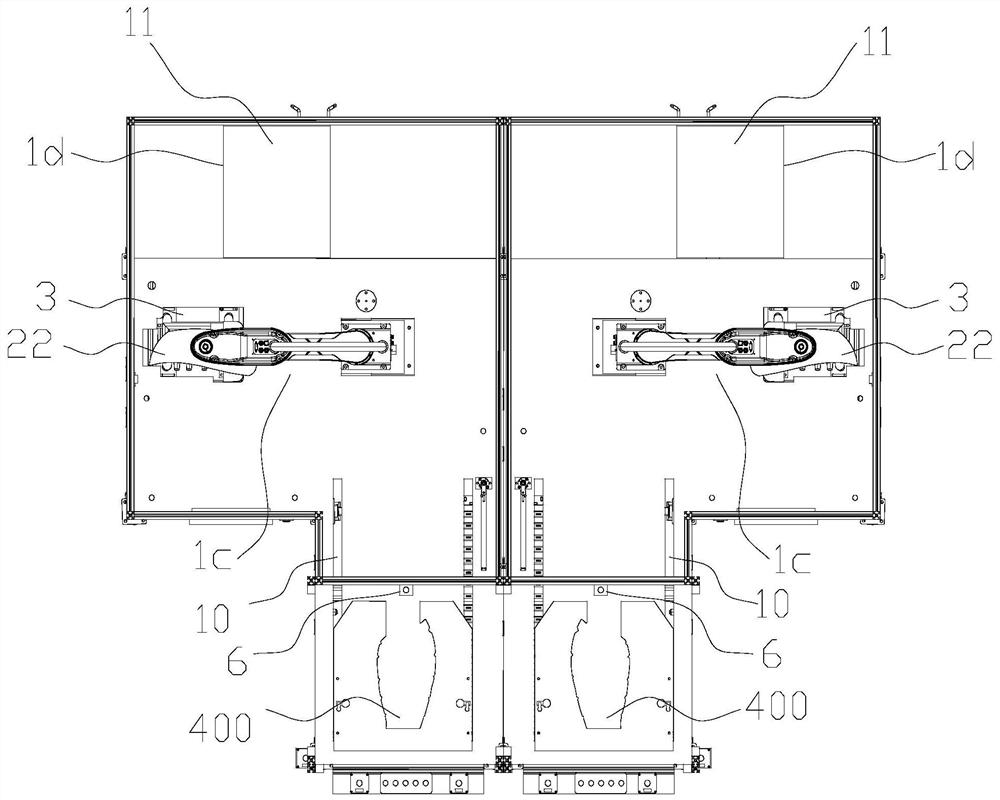

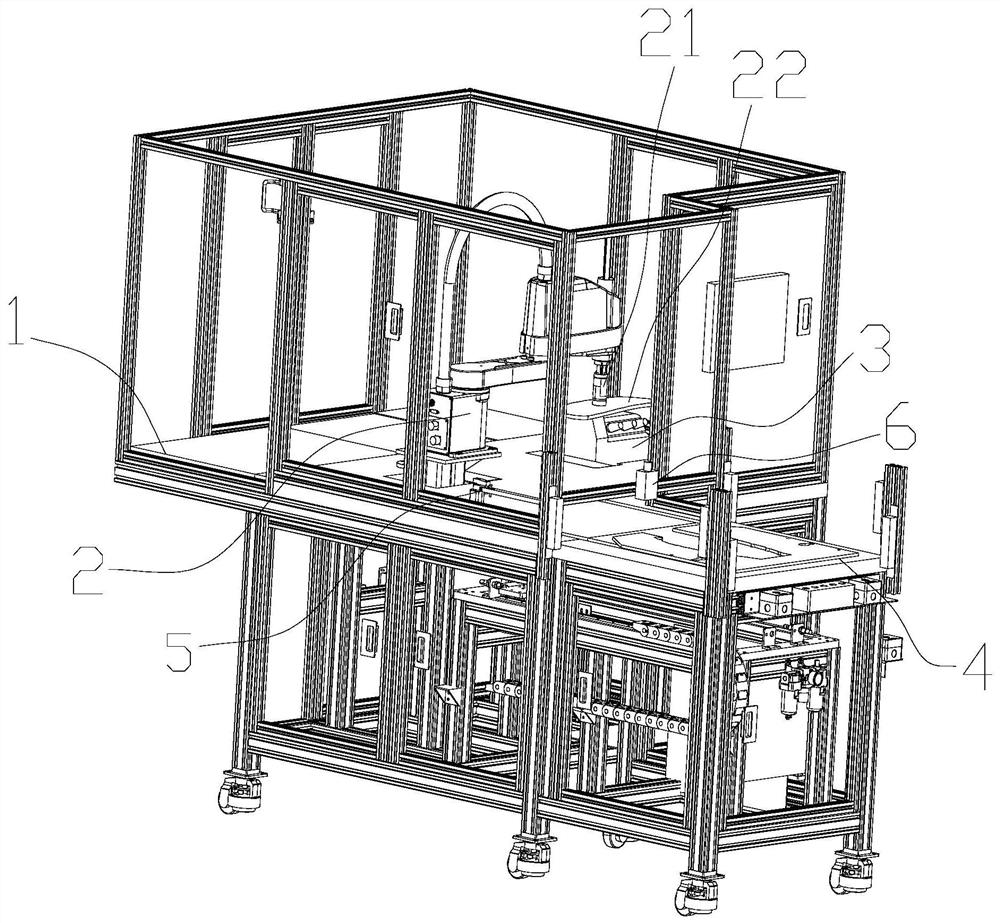

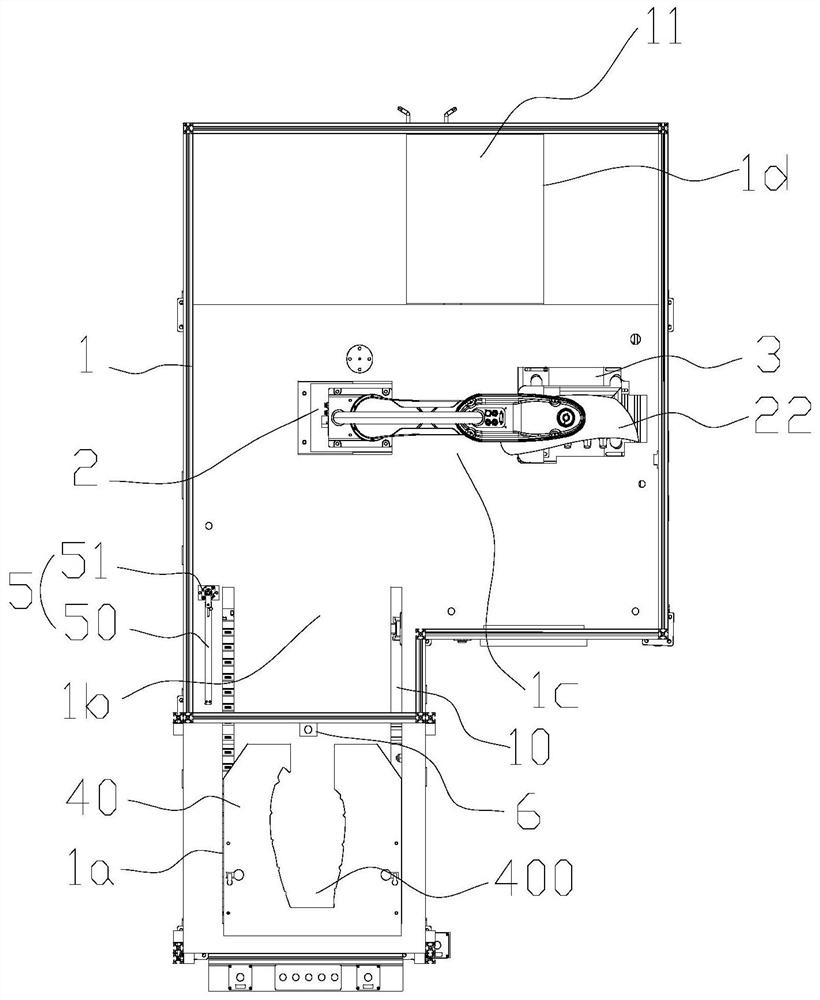

[0034] first reference Figure 1 to Figure 13 The shown automatic sewing equipment for car seat covers includes at least one sewing device, and the sewing device mainly includes a horizontally arranged workbench 1. As shown in the figure, an industrial robot 2 is arranged on the workbench 1. This implementation In the example, the workbench 1 is roughly L-shaped, on which an industrial robot 2 is installed near the middle, and the operating end of the industrial robot 2 can move in six directions of freedom, front, back, left, right, up and down, and the workbench 1 corresponds to the position of the industrial robot 2. The working area is respectively equipped with a cut piece waiting area 1b, a cut piece sewing area 1c and a finished product discharge area 1d, wherein the cut piece sewing area 1c is equipped with a servo sewing machine 3, and the industrial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com