Manufacturing method of flame-retardant colored elbow yarn wall-to-wall carpet

A manufacturing method and elbow technology, applied in the direction of yarn, carpet, textile and paper making, etc., can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0047]In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments.

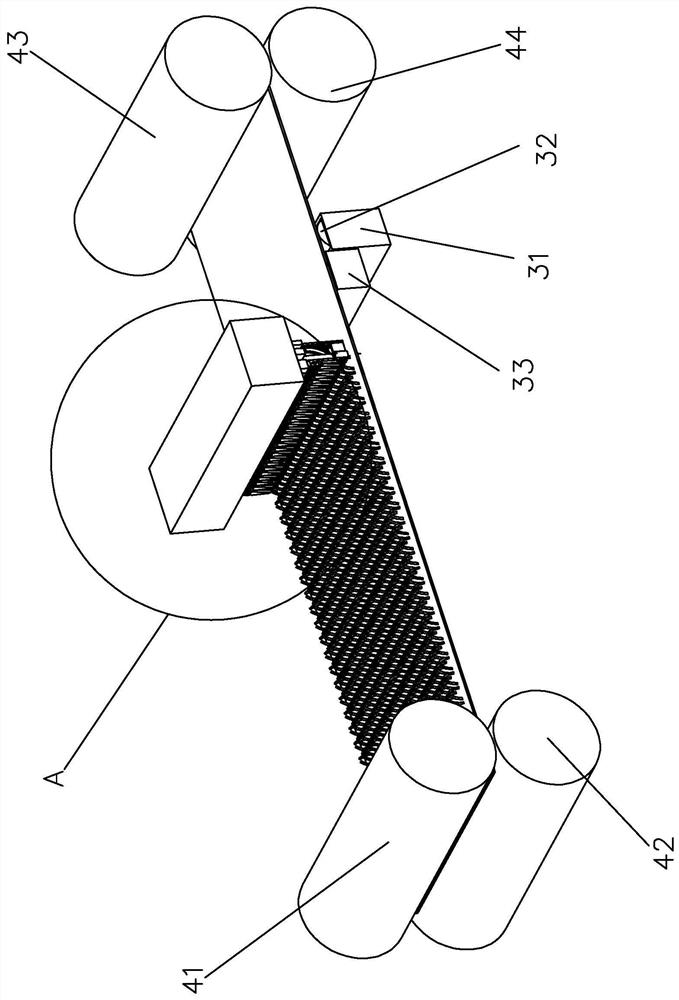

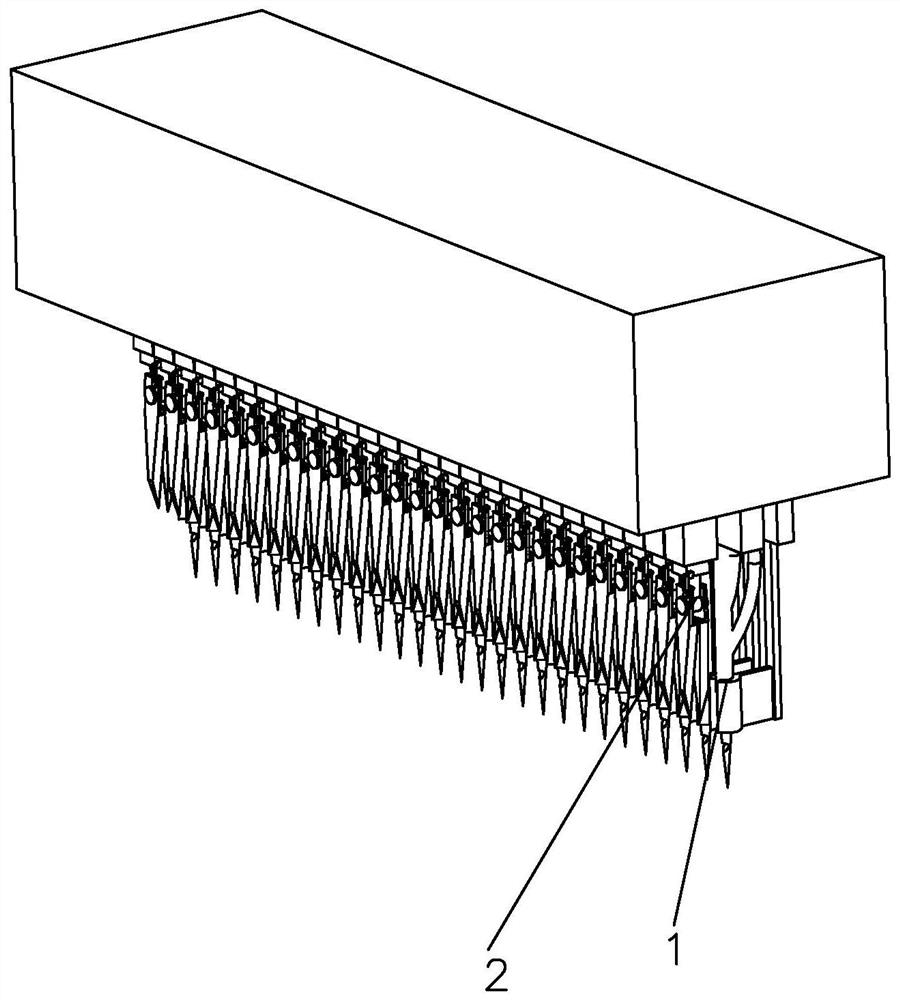

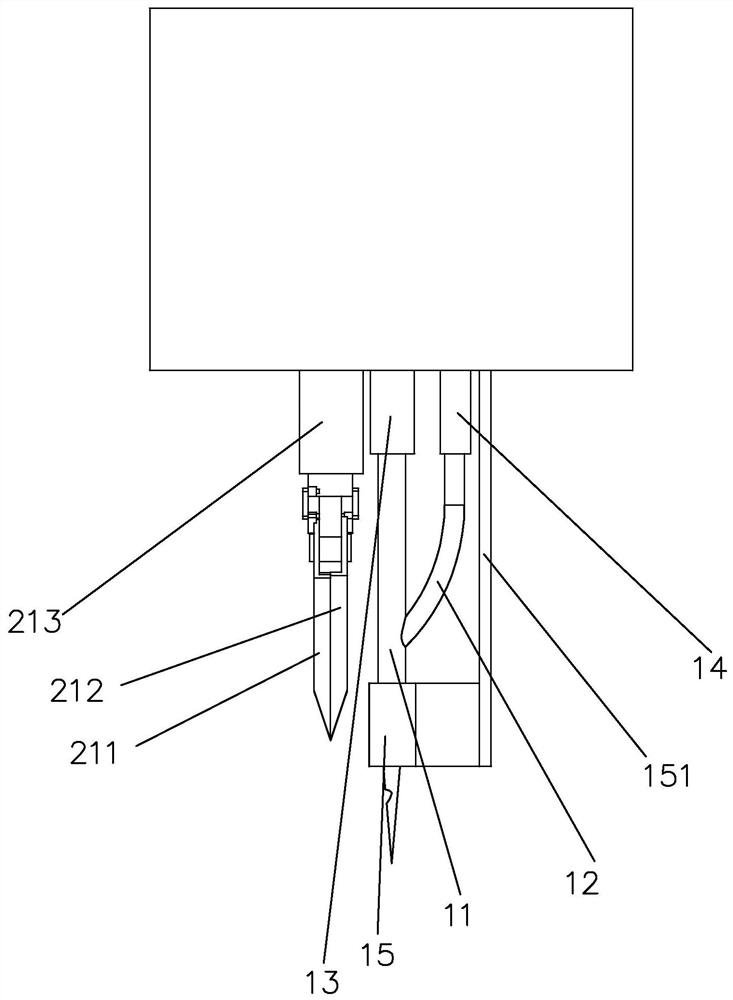

[0048]Such asFigure 1-5As shown, there is provided a method for making a blanket of flame-retardant colored curved yarn, which includes the following steps:

[0049](1) Spinning after melting polyester chips, flame-retardant materials and masterbatch;

[0050](2) Twist and shape the yarn spun in step (1);

[0051](3) Tuft the yarn twisted and shaped in step (2),

[0052](4) Gluing and fixing the tufted carpet in step (3) to obtain a tufted carpet;

[0053](5) Carry out carpet surface covering on the tufted carpet prepared in step (4).

[0054]Preferably, in step (1), a flame-retardant material with a mass percentage of 30-40% and a polyester chip with a mass percentage of 60-70% are used to melt to form a flame-retardant mixture. The flame retardant material is a copolymerized primary phosphorus flame retardant, and the polyester chip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap