Assembly type built-in corrugated steel plate reinforced concrete cross-shaped section component and construction process

A technology for reinforcing concrete and corrugated steel plates, which is used in building components, building structures, building insulation materials, etc. Sudden changes and other problems, to achieve the effect of good overall performance of the structure, increased bending moment of inertia, and strong shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

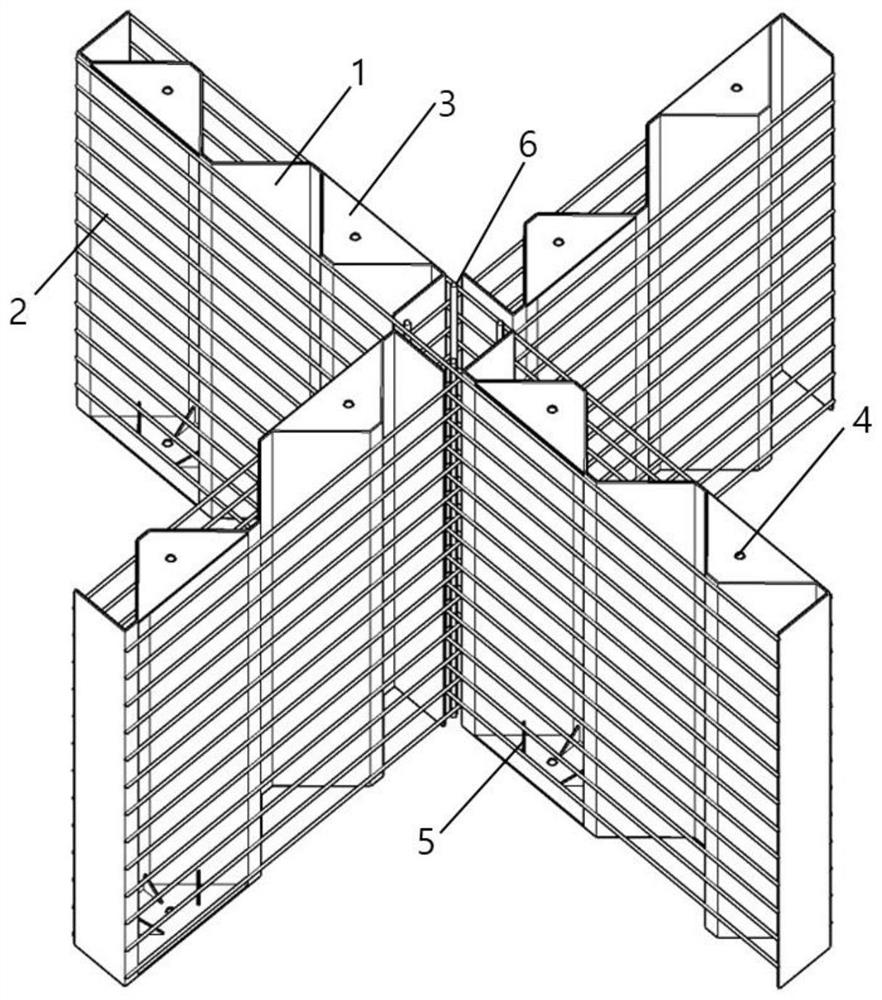

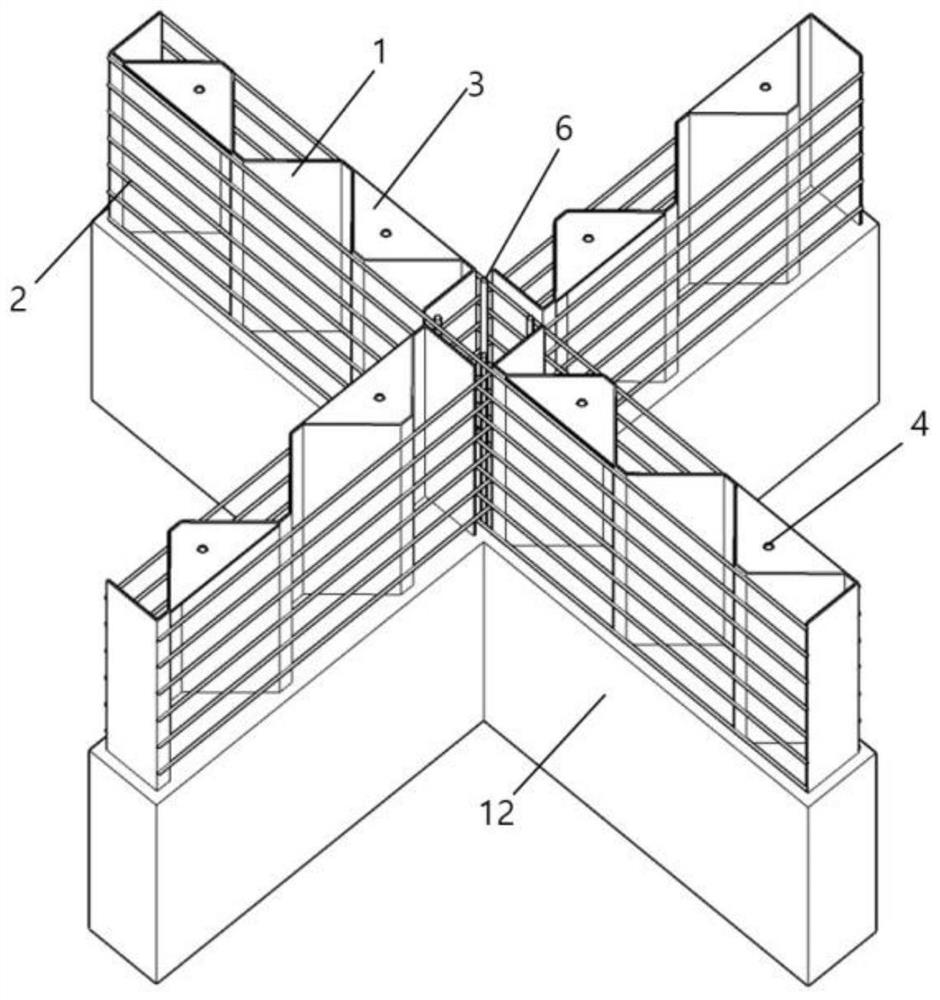

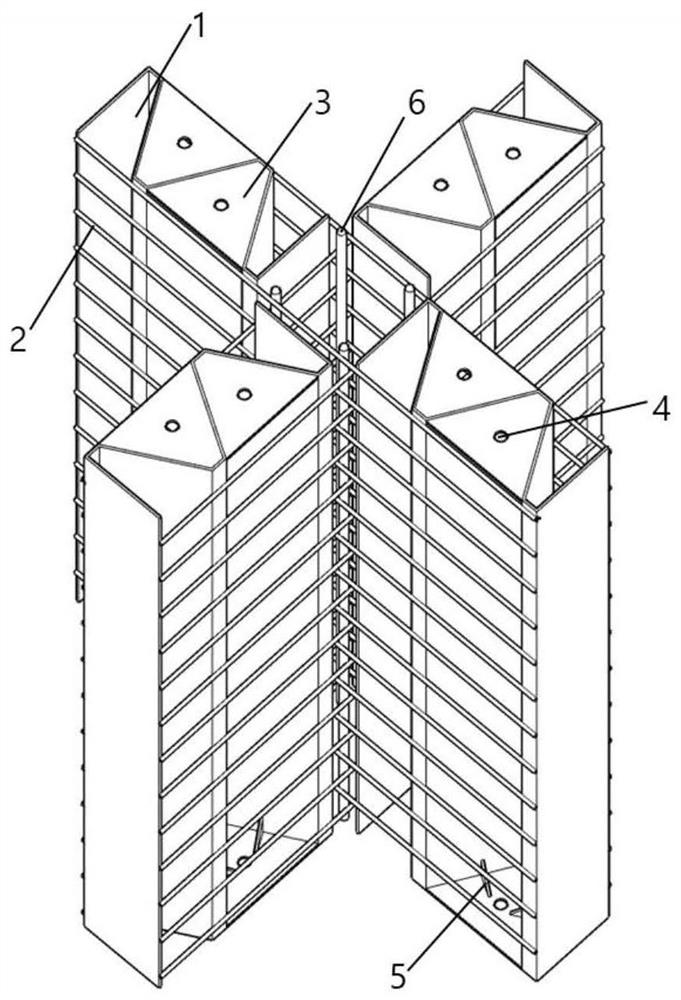

[0050] Such as figure 1 , 3, 5, and 7, the present embodiment discloses a corrugated steel plate 1, a concrete 12, a steel strip 2 and a horizontal butt joint steel plate 3; The surface welded steel strips 2 form a ten-shaped steel skeleton, and the corrugated steel plate 1 has an isosceles trapezoidal waveform;

[0051] Concrete 12 is poured on the ten-shaped steel skeleton to form the assembled built-in corrugated steel plate reinforced concrete ten-shaped section member; it can better ensure the integrity of the steel skeleton, better restrain the concrete, and increase the gap between the corrugated steel plate and the concrete. Mechanical interlocking force, thereby improving the bearing capacity of components.

[0052] In the intersecting area where the ten-shaped steel skeleton is perpendicular to the two directions of the ten-shaped cross-section, the steel strips 2 are arranged in a staggered manner, and the longitudinal steel bars 6 are arranged at the staggered po...

Embodiment 2

[0067] Such as figure 2 , 4 , 6, and 7, this embodiment discloses a prefabricated built-in corrugated steel plate reinforced concrete ten-shaped column member, which is different from embodiment 1 in that the assembled built-in corrugated steel plate reinforced concrete ten-shaped column member in this embodiment The length of the column body is 1043mm, the column thickness is 300mm, the ratio of the length h of the column body to the column thickness b is less than or equal to 4, and the thickness of the corrugated steel plate 1 arranged in it is 4-6mm, and the waveform is isosceles trapezoidal. The gradation of the concrete poured by the ten-shaped column member is grade two, and the maximum particle size of the coarse aggregate shall not exceed 25mm. In order to ensure that the concrete can be vibrated and compacted smoothly, the wave length 10 of the corrugated steel plate arranged in the ten-shaped column member is 40-60 mm, and the maximum bending angle 9 is 30 degrees...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap