Temperature monitoring device of aluminum profile extrusion die

A technology for extrusion dies and monitoring devices, which is applied in the direction of measuring devices, thermometers, and electrical devices, and can solve the problems of inconvenient temperature monitoring of extrusion dies and increased requirements for extrusion dies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

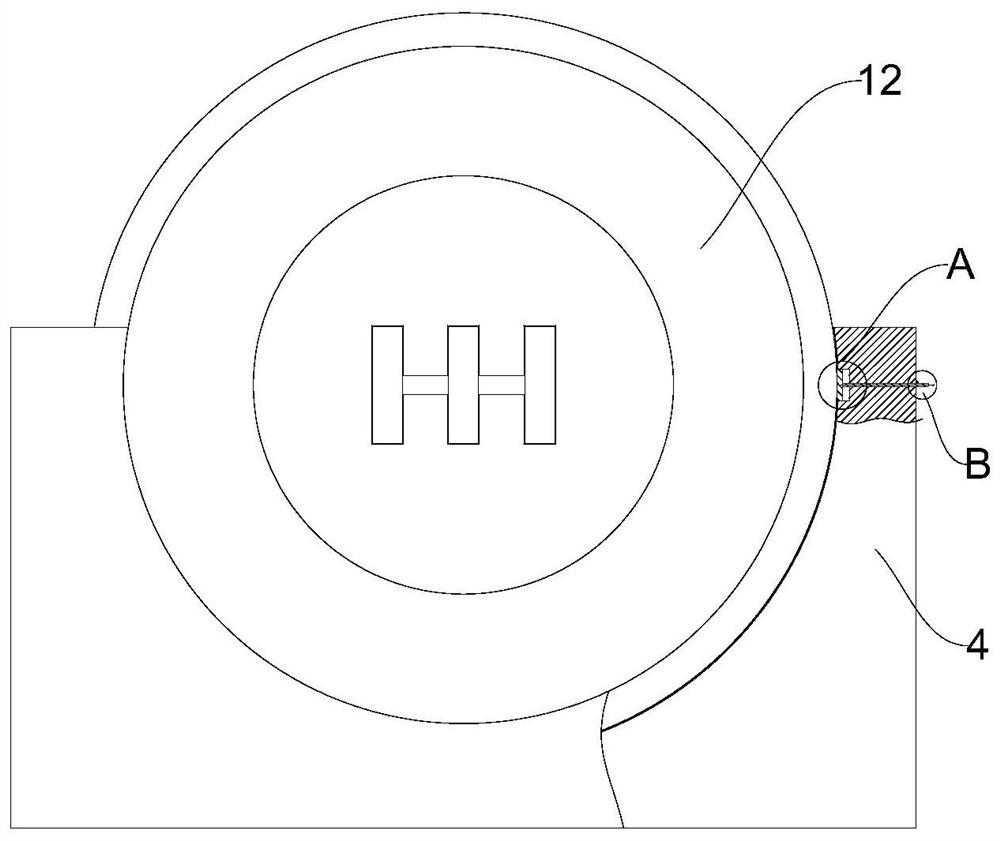

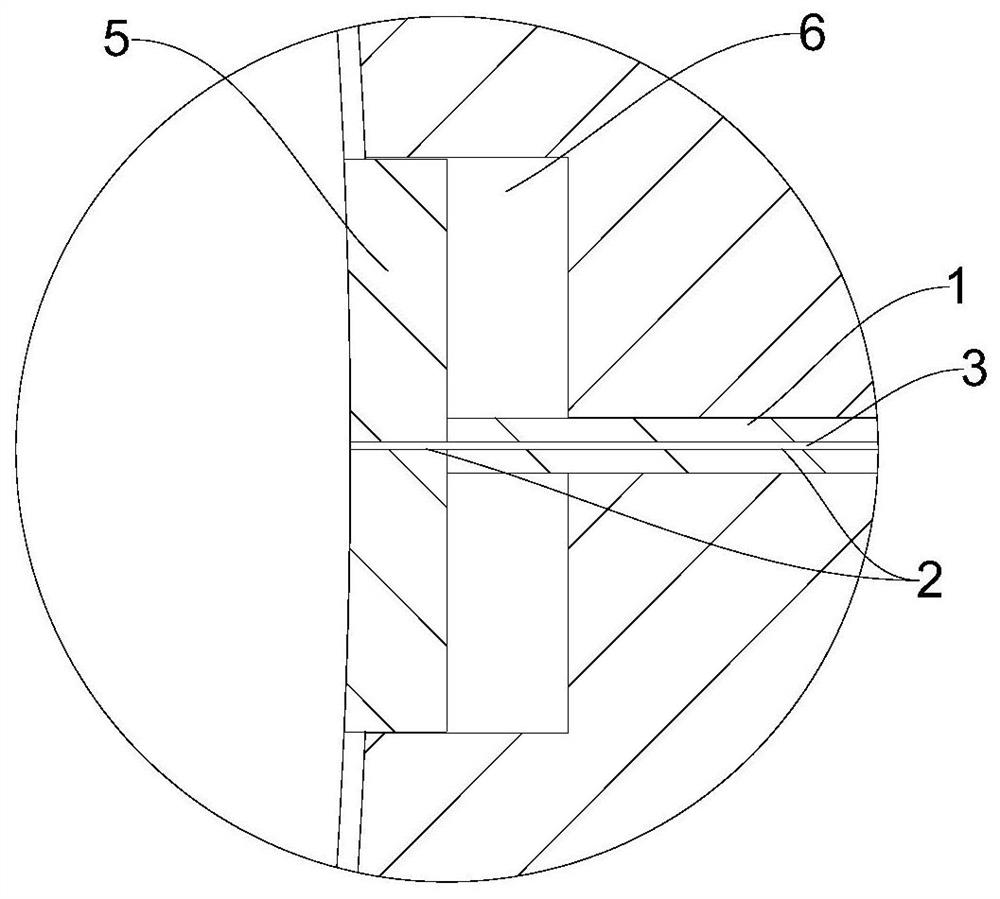

[0024] see Figure 1~4 , a temperature monitoring device for an aluminum profile extrusion die, comprising a mold base 4, a heat conduction block 5 and a thermocouple 3, the side of the heat conduction block 5 and the mold is an arc surface, and the mold base 4 is provided with a heat conduction block 5 The accommodating cavity 6, the heat conduction block 5 is provided with a control rod 1 that runs through the mold and is connected to the heat conduction block 5, the heat conduction block 5 and the control rod 1 are provided with an installation channel 2, and the thermocouple 3 is inserted in the installation channel 2 and the extrusion mold 12 clinging.

[0025] In this example, put the extrusion die 12 on the mold base 4, then move the control rod 1 to make the heat conduction block 5 in the accommodating cavity 6 close to the extrusion die 12, and finally insert the thermocouple 3 on the heat conduction block 5 1. The installation channel 2 of the control rod 1 is close...

Embodiment 2

[0027] see Figure 1~4 , a temperature monitoring device for an aluminum profile extrusion die, comprising a mold base 4, a heat conduction block 5 and a thermocouple 3, the side of the heat conduction block 5 and the mold is an arc surface, and the mold base 4 is provided with a heat conduction block 5 The accommodating cavity 6, the heat conduction block 5 is provided with a control rod 1 that runs through the mold and is connected to the heat conduction block 5, the heat conduction block 5 and the control rod 1 are provided with an installation channel 2, and the thermocouple 3 is inserted in the installation channel 2 and the extrusion mold 12 clinging.

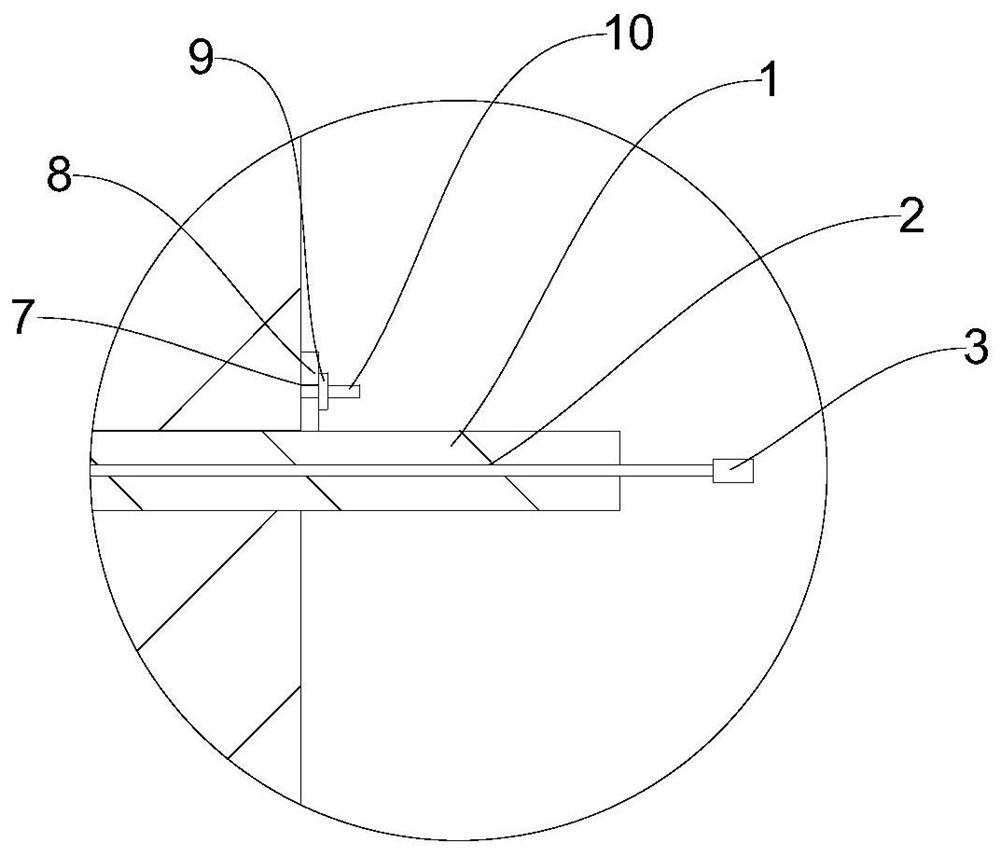

[0028] The control rod 1 is provided with a limit plate 8, the limit plate 8 is provided with a limit through hole 7, the mold base 4 is provided with a threaded column 10 inserted into the limit through hole 7, and the threaded column 10 is provided with a locking limit The nut 9 of the plate 8, when the heat conduction...

Embodiment 3

[0032] see Figure 1~4 , a temperature monitoring device for an aluminum profile extrusion die, comprising a mold base 4, a heat conduction block 5 and a thermocouple 3, the side of the heat conduction block 5 and the mold is an arc surface, and the mold base 4 is provided with a heat conduction block 5 The accommodating cavity 6, the heat conduction block 5 is provided with a control rod 1 that runs through the mold and is connected to the heat conduction block 5, the heat conduction block 5 and the control rod 1 are provided with an installation channel 2, and the thermocouple 3 is inserted in the installation channel 2 and the extrusion mold 12 clinging.

[0033] The heat conduction block 5 adopts a heat conduction material, and the heat conduction material is beneficial to transfer the temperature of the extrusion die 12 to the thermocouple 3 in the heat conduction block 5 .

[0034] Other parts of this embodiment are the same as those of Embodiment 1, and will not be rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com