Nondestructive testing equipment and nondestructive testing method

A non-destructive testing and equipment technology, applied in the direction of using radiation for material analysis, etc., can solve the problems of increasing the labor intensity of boarding operators, and achieve the effects of improving equipment use efficiency, optimizing operation process, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

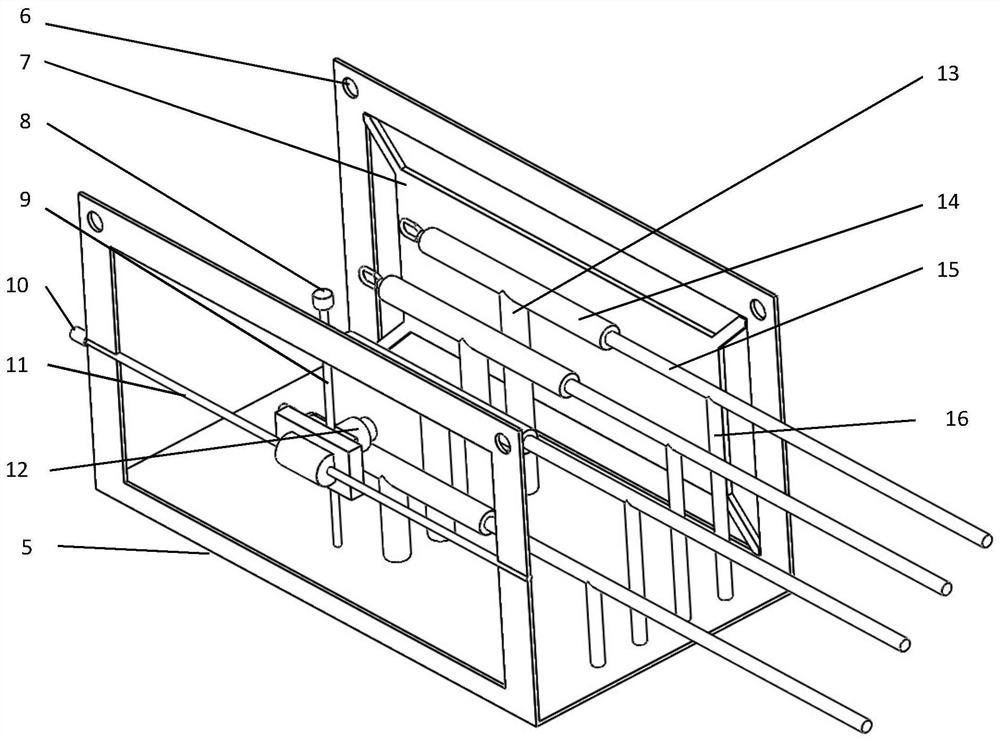

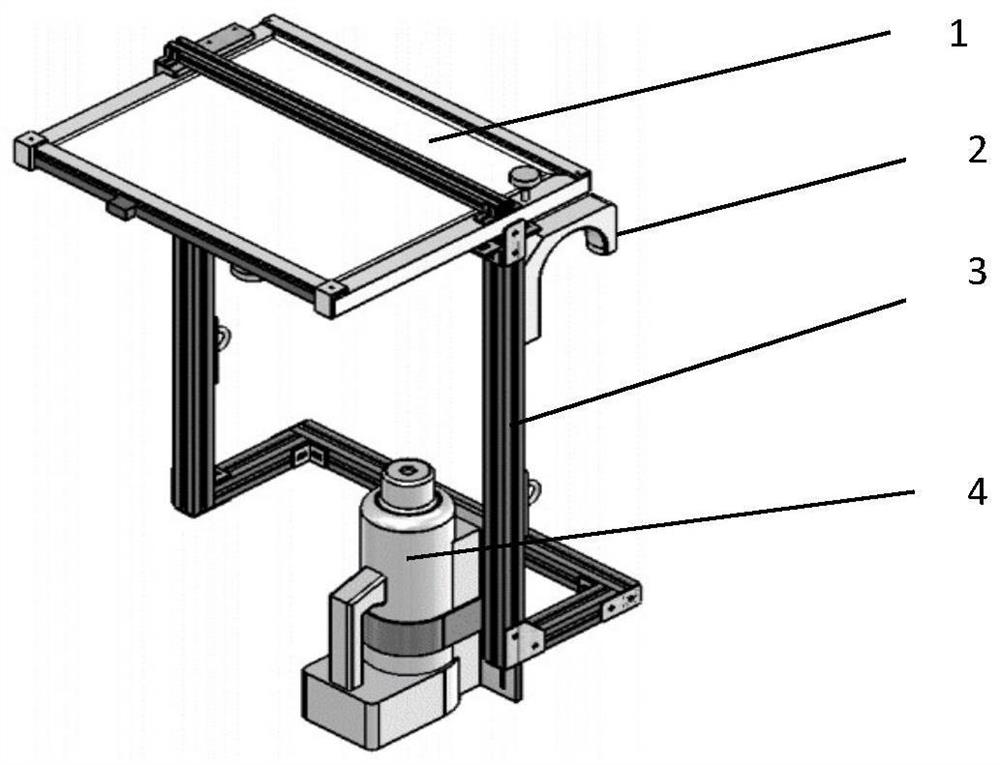

[0045] Existing complete sets of X-ray imaging technology devices such as figure 2 shown. The main components are an X-ray pulse machine A4, a digital flat panel detector A1, a U-shaped groove 2 and a bracket 3 to assemble a detection device.

[0046]In the existing non-destructive testing of the crimping quality of tension clamps, after the crimping operation is completed at high altitude and the wire is hung, the non-destructive testing personnel carry the non-destructive testing device to carry out the high-altitude operation, and carry out the non-destructive testing of the crimping quality of the strain clamps at high altitude. When carrying out non-destructive testing of the crimping quality of the tension clamp, it needs to be suspended on the tension clamp through the U-shaped groove 2 to ensure the relative position of the detection device and the tension clamp. Due to the long crimping length of the tension clamp, it is necessary to use the non-destructive testing ...

Embodiment 2

[0065] After the crimping operation of the strain clamp is completed, the crimping-related equipment in the aerial work platform for the dismantled crimping can be used for non-destructive testing of the strain clamp.

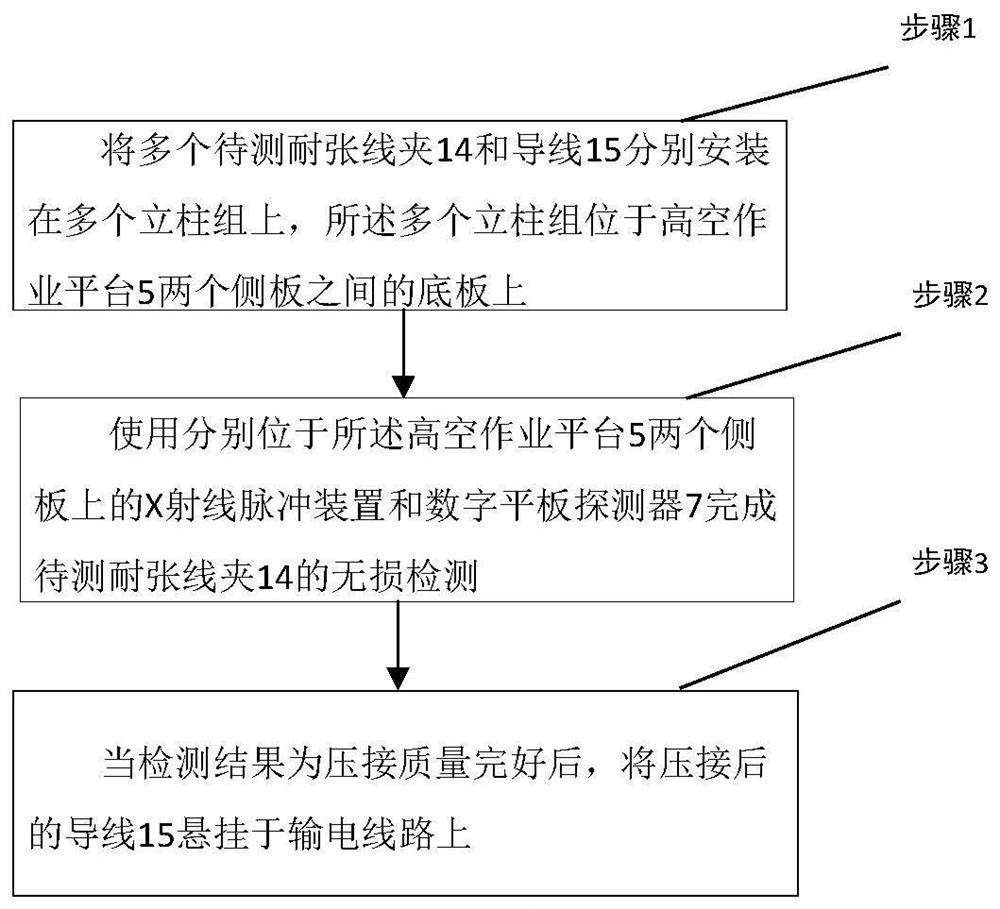

[0066] A non-destructive testing method such as image 3 shown, including:

[0067] Step 1: install a plurality of tension clamps 14 and wires 15 to be tested on a plurality of column groups respectively, and the plurality of column groups are located on the bottom plate between the two side plates of the aerial work platform 5;

[0068] Step 2: use the X-ray pulse device and the digital flat panel detector 7 respectively located on the two side plates of the aerial work platform 5 to complete the non-destructive testing of the tension clamp 14 to be tested;

[0069] Step 3: When the test result shows that the crimping quality is intact, hang the crimped wire 15 on the power transmission line.

[0070] Step 2: Using the X-ray pulse device and the digital flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com