Method for Determination of Titanium/Titanium Alloy β Phase Transition Temperature Based on Dynamic Thermal Simulator

A technology of phase transition temperature and titanium alloy, which is applied in the preparation of test samples, investigation stage/state change, material thermal expansion coefficient, etc., can solve the problems of small workload, insignificant thermal effect, and impact on measurement accuracy, so as to reduce the number of tests The workload, sample preparation requirements are simple, and the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] In the following examples, the method for measuring the β phase transition temperature of titanium / titanium alloys of the present invention is described in detail by taking TC4 titanium alloy as an example, but it should not be understood as a limitation of the present invention, and the present invention is equally applicable to titanium / other titanium alloys.

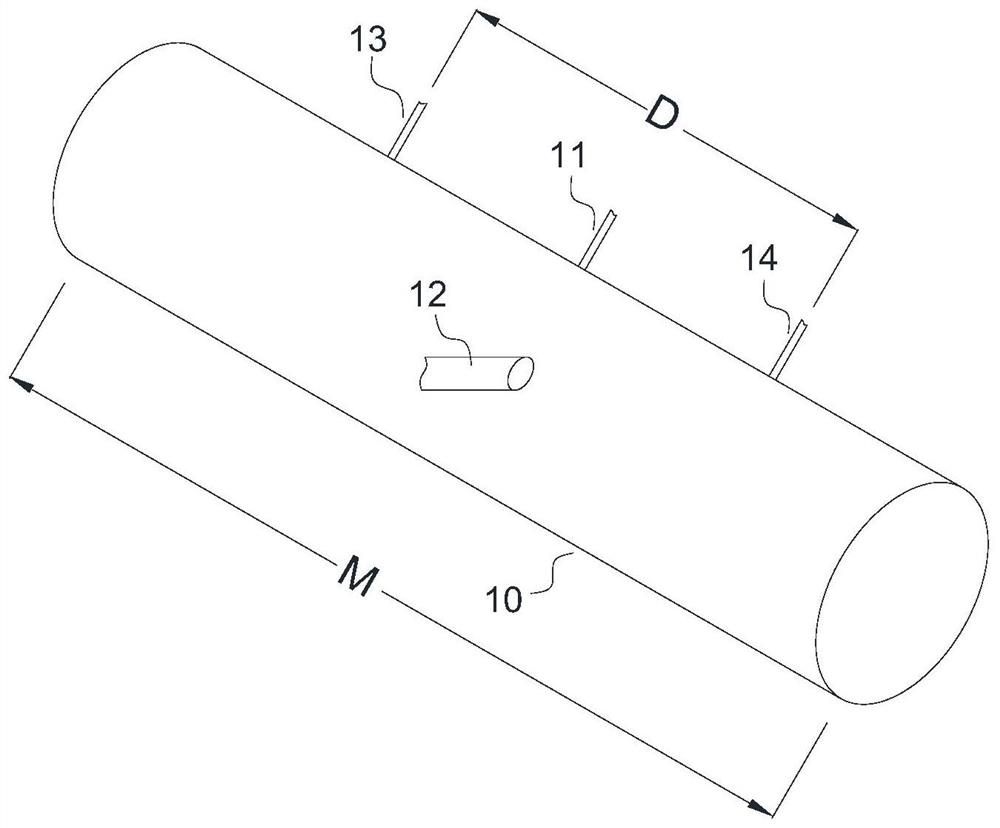

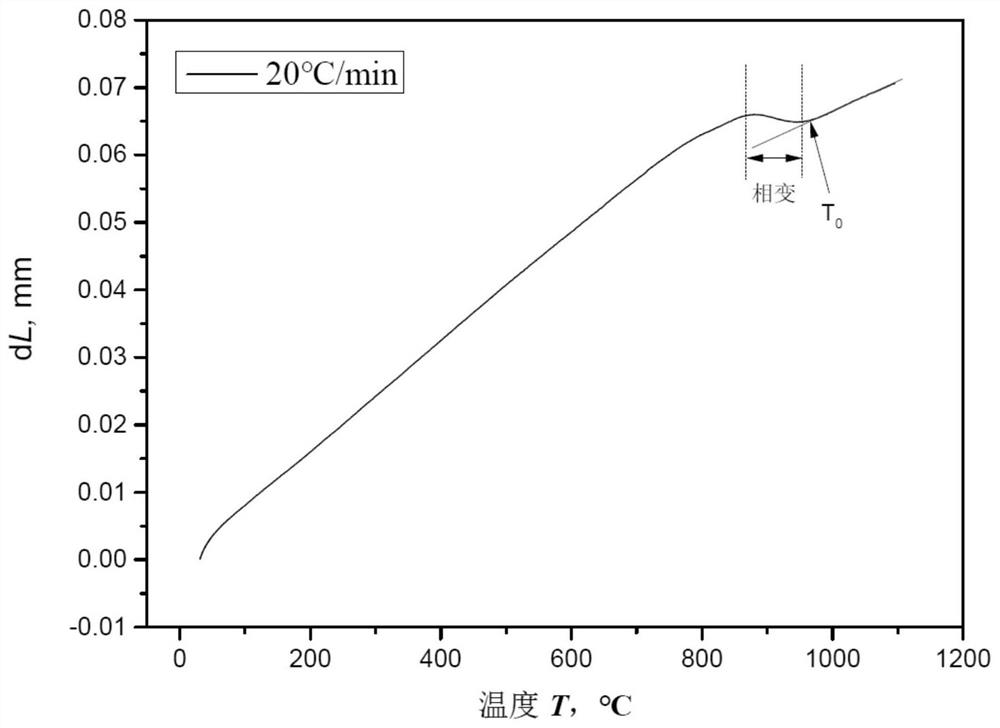

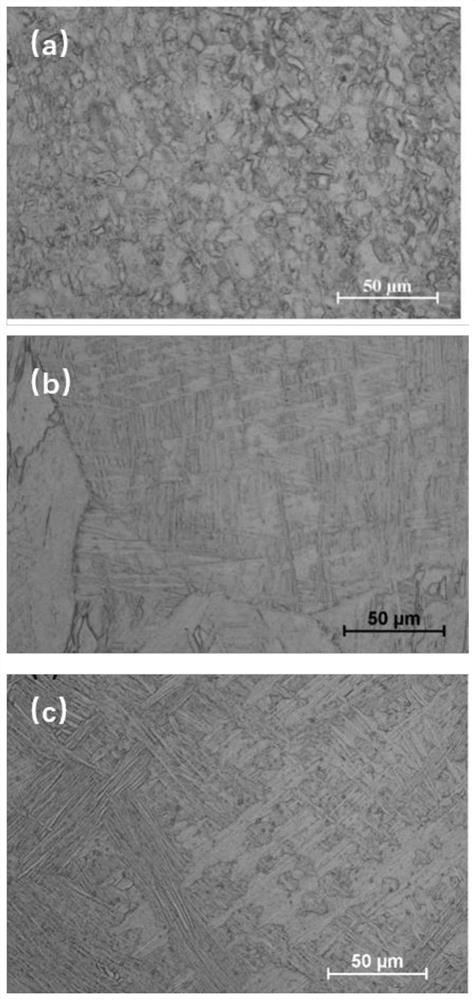

[0036] The method for measuring the β-phase transition temperature of titanium / titanium alloy based on a dynamic thermal simulator in this embodiment includes the steps of: sample preparation; thermal expansion test; sample quenching; β phase transition temperature. The dynamic thermal simulator is an existing equipment, for example, the GLEEBLE series dynamic thermal simulator of DSI Company of the United States can be used, which can be obtained from the market, so in the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com