Tunnel face supporting pressure design method

A design method and technology of the faceplate, applied in the fields of instruments, geometric CAD, electrical and digital data processing, etc., can solve the problems of inaccuracy, time-consuming, low efficiency, etc., and achieve shortened iteration time, saved calculation time, and simple definition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

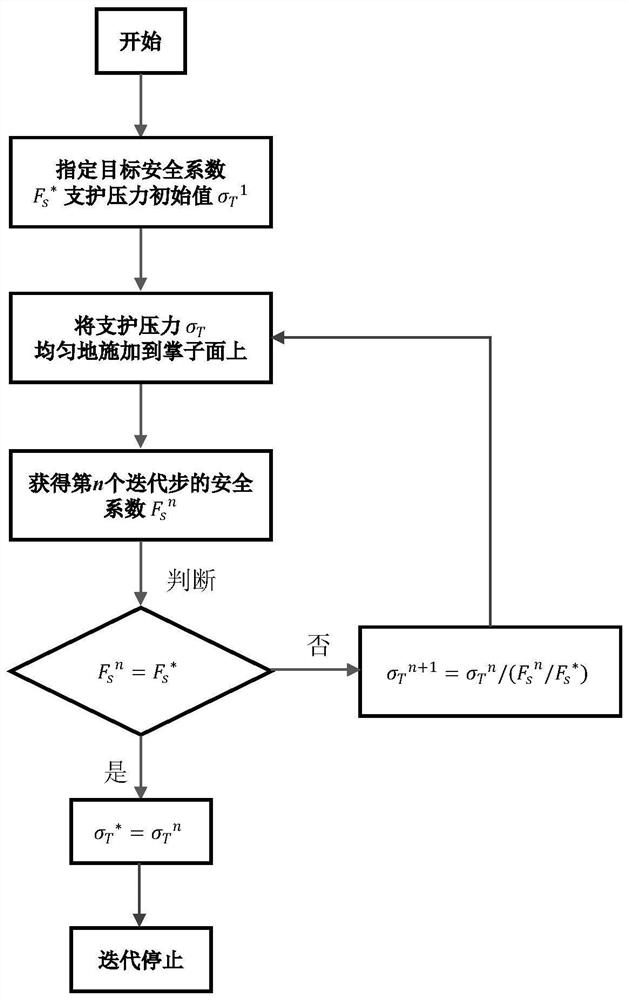

[0039] as attached figure 1 As shown, the present invention provides a tunnel face support pressure design method, which is used for design and calculation to determine the ultimate support pressure required to maintain the stability of the face of the tunnel structure and the corresponding value based on a given target safety factor The target support pressure value of . Specifically, the tunnel face support pressure design method includes the following steps:

[0040] Step S1, setting the target safety factor for maintaining the short-term stability of the tunnel face and the initial value of the support pressure according to the current engineering situation.

[0041] In step S1, the minimum set value of the target safety factor is 1.0, and the initial value of the support pressure is less than the initial ground stress. When the safety factor is less than 1, the tunnel is in an unstable state, and when the safety factor is greater than or equal to 1, the tunnel is in a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com