Liquor cold immersion and countercurrent extraction methods and online quality control methods of polysaccharides from Polygonatum polysaccharides in the brewing process

A technology for countercurrent extraction and Polysaccharide Polysaccharide, applied in the field of extraction, can solve the problems of few analysis steps, short time consumption, few error influencing factors and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

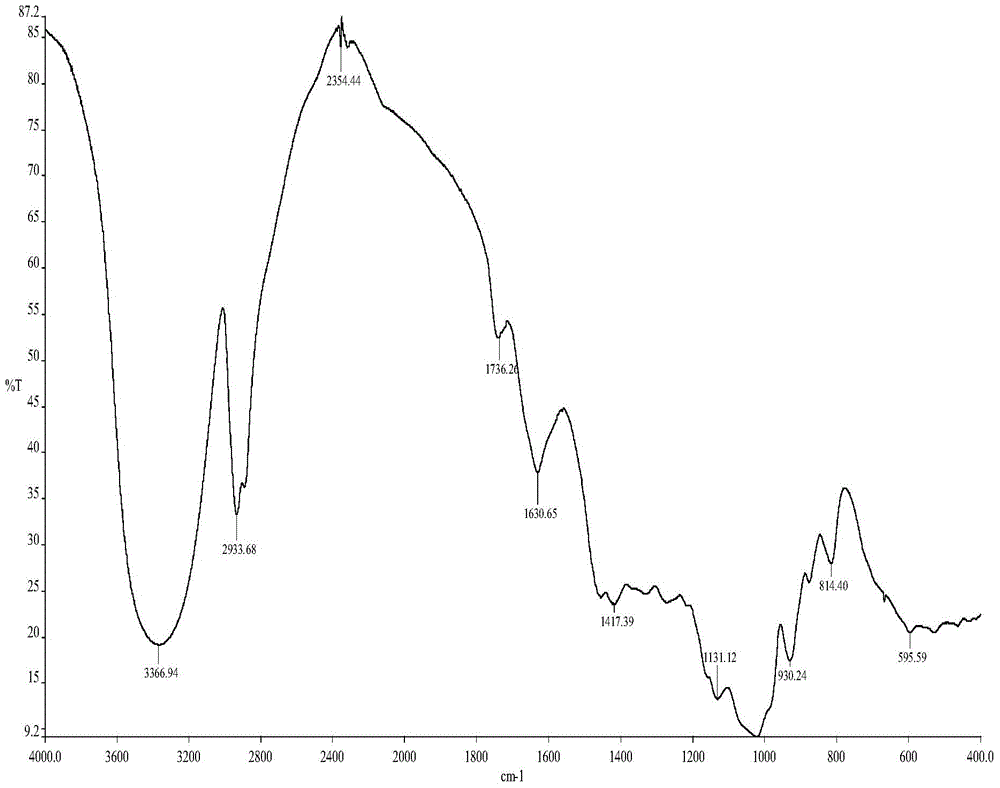

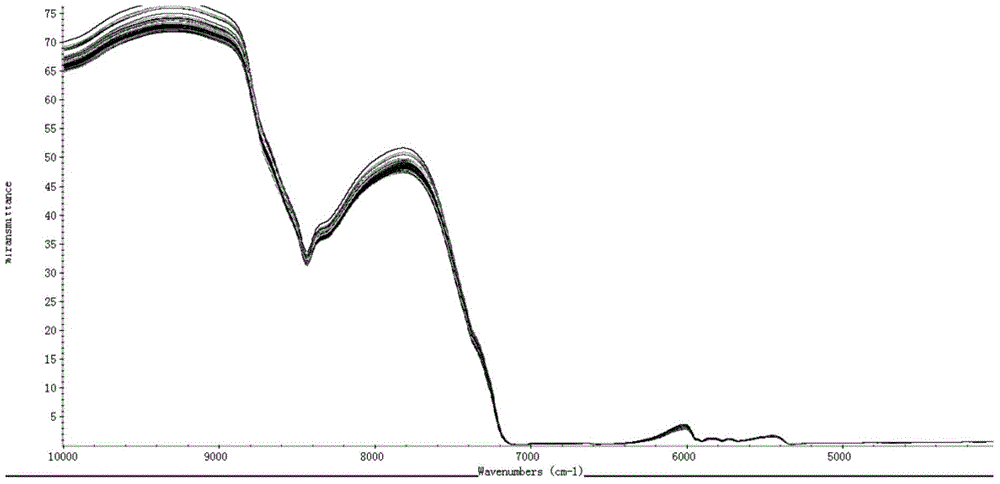

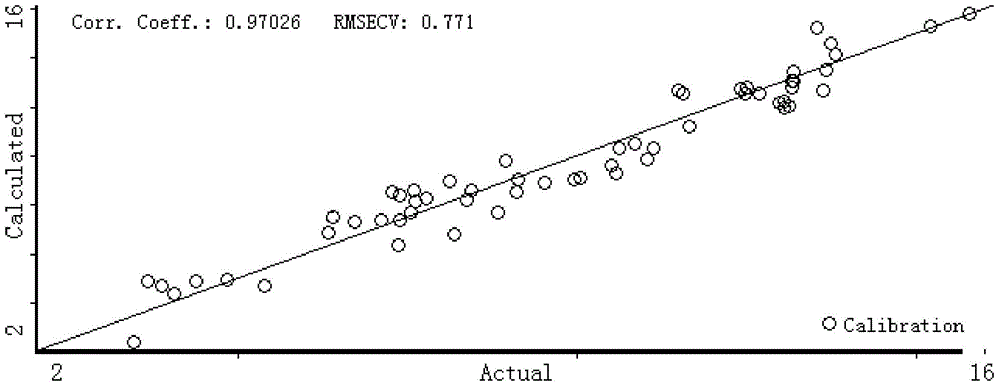

Method used

Image

Examples

Embodiment 1

[0091] Example 1, take an appropriate amount of Yuzhu decoction pieces, crush them into granules of 0.1-0.3 cm, add 50-degree white wine at a feed ratio of 1:7.5, cold-soak overnight, and extract in countercurrent at a temperature of 50-70 °C (countercurrent circulation speed 1.0T / h *5kg) for about 6-8 hours, collect the extract, use it as extract-1, and set aside, add 50% white wine for the second time in the same way, and cold soak for 16-64 hours (Friday, Saturday, and Sunday are recommended for a total of 3 days) , countercurrent extraction during the day (countercurrent circulation speed 1.0T / h) for about 6-8h, collect the extract-2 and set aside. Combine the two extracts 1 and 2 as the stock solution, store it for later use, filter it with diatomaceous earth before use, and blend according to the established process.

Embodiment 2

[0093] Take appropriate amount of Yuzhu decoction slices, crush or cut into 0.6-1cm particles, flatten, or crush and then cut into 0.6-1cm particles, add 50% white wine at a ratio of 1:7.5, cold soaking temperature: site temperature 10 -35 degrees, heating countercurrent temperature: 50-70℃, countercurrent circulation speed 1.0T / h, cold soaking + countercurrent extraction time is 24-72 hours, "cold soaking - countercurrent - cold soaking - countercurrent" interval, cold soaking time : Heating countercurrent time = 2:1~8:1, collect the extract -1, set aside, add 50% white wine for the second time in the same way, "cold soaking - countercurrent - cold soaking - countercurrent" alternately extract, collect and extract Liquid-2, spare. Combine the 2 extractions, use it as a stock solution, store it for later use, filter it with diatomaceous earth before use, and blend according to the established process.

[0094] Take an appropriate amount of Polygonatum odoratum extract (about ...

Embodiment 3

[0097] Take an appropriate amount of Yuzhu decoction pieces, break into small particles of 0.1-0.3cm, or cut into 0.6-1cm particles and flatten, or flatten and cut into 0.6-1cm particles, add 50% white wine respectively according to the ratio of 1:7.5, Cold soak overnight for 16 hours, extract at room temperature countercurrently for about 6-8 hours during the day, extract for 2 days, collect the extract-1, and set aside, add 50-degree white wine for the second time in the same way, and cold soak overnight (it is recommended to extend the time to 3 days, that is, , use Friday, Saturday, and Sunday to stand still), during the daytime, countercurrent extraction at room temperature for about 6-8 hours, collect the extraction solution-2, and set aside. Blend according to the established process (note that the volume of Polygonatum odoratum has doubled).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com