Method and device for quickly oxidizing ammonia nitrogen

An oxidation device, ammonia nitrogen technology, applied in the field of analytical instruments, can solve the problems of no ammonia nitrogen oxidation device, cumbersome operation steps, long time consumption, etc., and achieve the effect of simple structure, flexible operation, fast and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: The steps of the ammonia nitrogen rapid oxidation method of the present embodiment are as follows:

[0032] a. Preheat the ammonia nitrogen water sample, after preheating, the solution temperature ranges from 18°C to 100°C;

[0033] b. Quickly add hypobromite oxidant to the ammonia nitrogen water sample preheated in step a, and immediately oxidize the ammonia nitrogen in the water sample to nitrite nitrogen.

[0034] Ammonia nitrogen refers to the free ammonia (NH 3 ) and ammonium ions (NH 4 ) in the form of nitrogen. In the oxidation method of this embodiment, after the ammonia nitrogen water sample is heated to a certain temperature, the hypobromite can complete the oxidation of ammonia nitrogen almost instantly, which is reduced from the 20min required in the standard to almost instantaneously, thereby saving ammonia nitrogen oxidation. time.

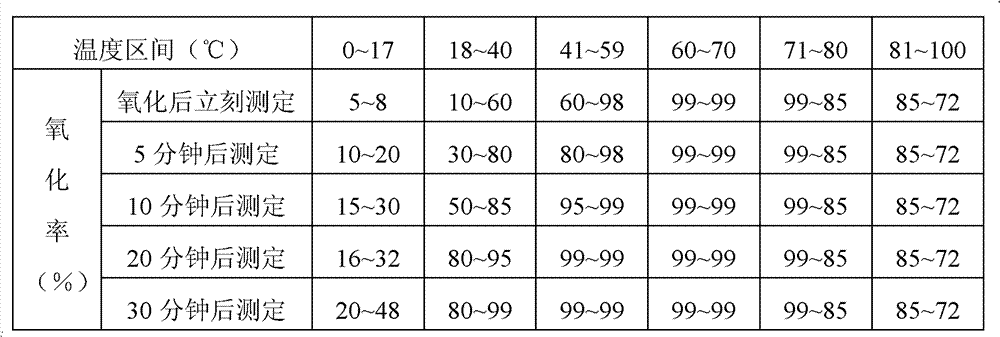

[0035] Preferably, the ammonia nitrogen preheating temperature is 60°C to 70°C. After a large number of ...

Embodiment 2

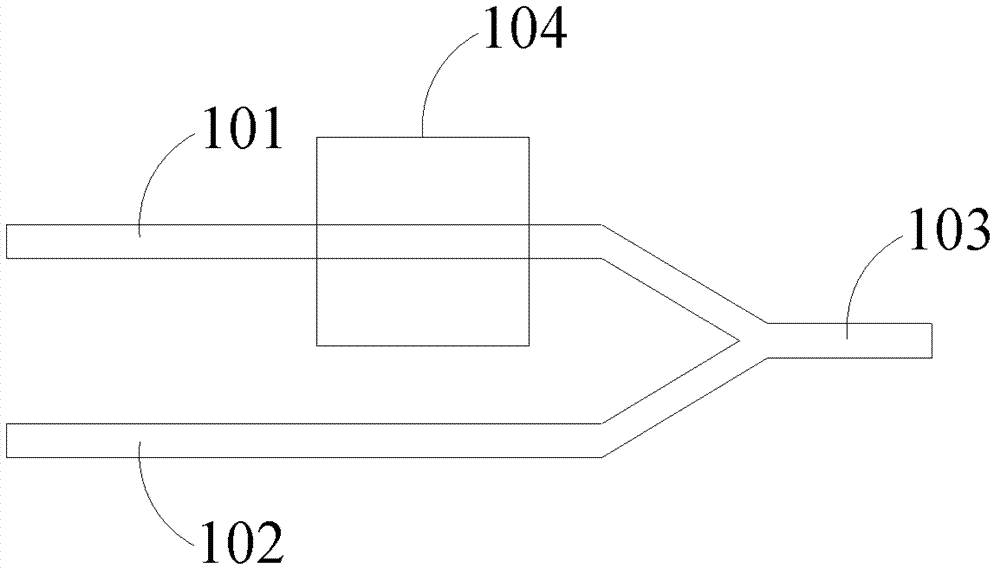

[0040] Embodiment 2: Combination figure 1 Illustrate the ammonia nitrogen oxidation device of this embodiment, which includes an ammonia nitrogen solution delivery branch pipe 101, an oxidant delivery branch pipe 102, a delivery main pipe 103 communicated with the ammonia nitrogen solution delivery branch pipe 101 and the oxidant delivery branch pipe 102, for outputting nitrite nitrogen The reactant, the heater 104 is arranged on the ammonia nitrogen solution delivery branch pipe 101 for preheating the ammonia nitrogen solution. When the ammonia nitrogen solution is heated by the heater 104 in the ammonia nitrogen solution delivery branch pipe 101, the heated ammonia nitrogen solution is mixed with the hypobromite solution in the oxidant delivery branch pipe 102 in the delivery main pipe 103, and the oxidation reaction occurs rapidly to generate hypobromite. Nitrate nitrogen, complete the oxidation of ammonia nitrogen solution. The heater 104 in this embodiment is a water bat...

Embodiment 3

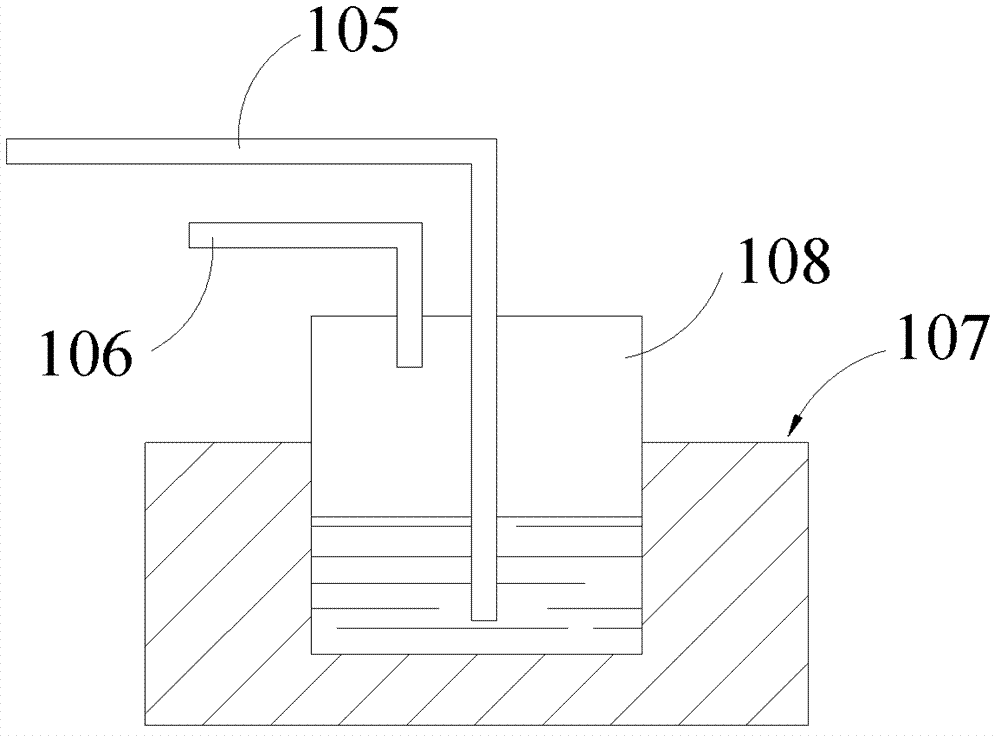

[0041] Example Three: Combining figure 2 The ammonia nitrogen oxidation device of the present embodiment is described, which includes an ammonia nitrogen solution delivery branch pipe 105, an oxidant delivery branch pipe 106, a water bath / oil bath heater 107 communicated with the ammonia nitrogen solution delivery branch pipe 105 and the oxidant delivery branch pipe 106 respectively. The output end of the ammonia nitrogen solution delivery branch pipe 105 is located in the reaction bottle 108 , and the output end of the oxidant delivery branch pipe 106 is located in the reaction bottle 108 . The bottom of the water bath / oil bath heater 107 is equipped with an electric heating tube, and the upper part is equipped with a temperature sensor. The electric heating tube and the temperature sensor are respectively connected to the automatic temperature controller installed outside the water bath / oil bath heater 107 for automatic control. Heating temperature for water bath or oil bat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com