Pipeline wall thickness obtaining method and system

An acquisition method and technology of pipeline wall, which is applied in the field of measurement and calculation of pipeline wall thickness, can solve the problem of unfavorable long-term monitoring and evaluation of pipeline quality and corrosion damage, does not take into account coupling, temperature and other deviation factors, and cannot accurately reflect pipeline wall Thick truth and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

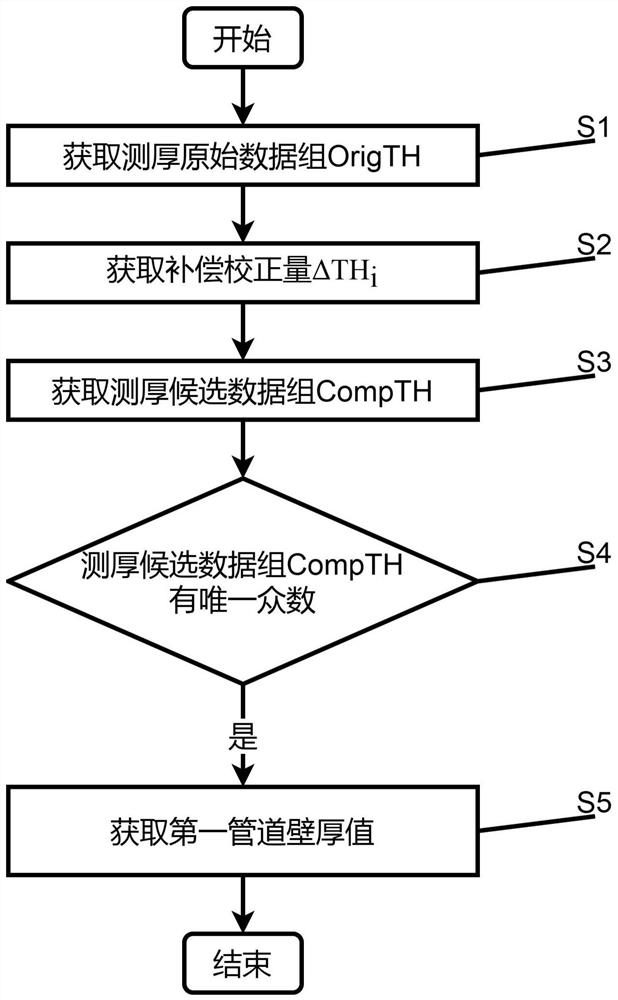

[0015] In an exemplary embodiment, such as figure 1 As shown, the pipeline wall thickness acquisition method includes S1 to obtain the original thickness measurement data set OrigTH, S2 to obtain the compensation correction amount ΔTH i , S3 obtains the thickness measurement candidate data set CompTH, S4 judges whether the thickness measurement candidate data set CompTH has a unique mode, and S5 the thickness measurement candidate data set CompTH has a unique mode, and there are five steps in total to obtain the first pipeline wall thickness value.

[0016] The S1 acquires the original thickness measurement data set OrigTH: use the thickness gauge in the preset a mode to perform c times of measurement at each time at the preset b times, and obtain a total of M data OrigTH i (1≤i≤m, i∈N, m∈N) form the thickness measurement raw data group OrigTH. The a, b, c, M are all non-zero natural numbers. The test mode, test time and the number of tests at each moment of the thickness ga...

Embodiment 2

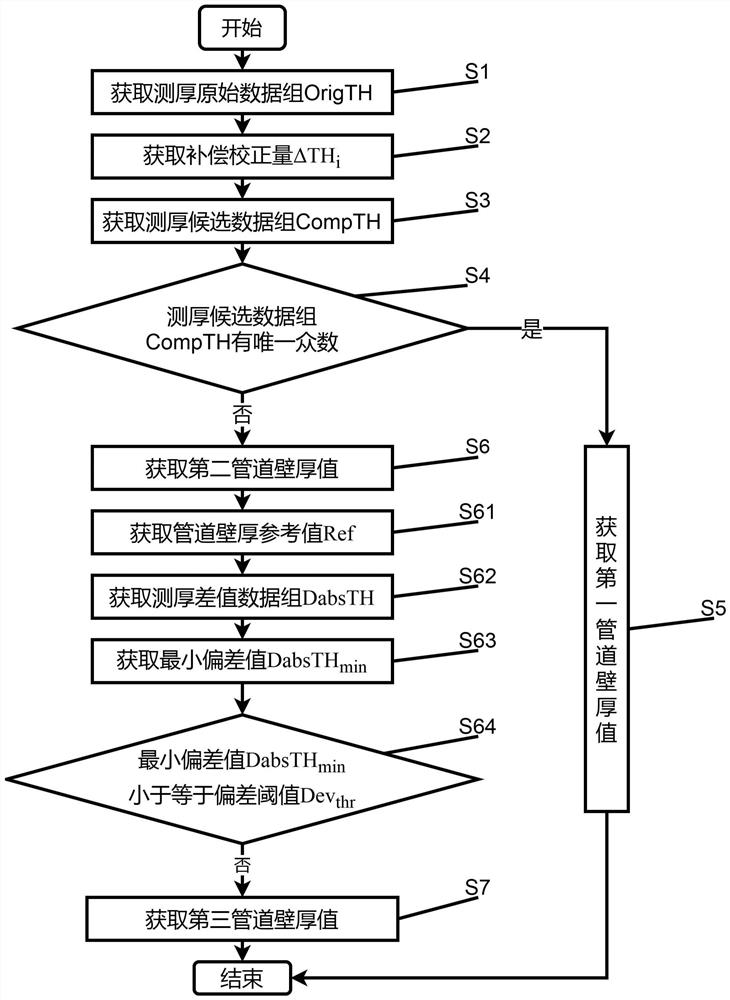

[0023] In this exemplary embodiment, if figure 2 As shown, the pipeline wall thickness acquisition method includes S1 to obtain the original thickness measurement data set OrigTH, S2 to obtain the compensation correction amount ΔTH i , S3 obtains the thickness measurement candidate data set CompTH, S4 judges whether the thickness measurement candidate data set CompTH has a unique mode, S5 the thickness measurement candidate data set CompTH has a unique mode, obtains the first pipeline wall thickness value, S6 thickness measurement candidate data set CompTH has no unique mode: S61 obtains the pipe wall thickness reference value Ref; S62 obtains the thickness measurement difference data set DabsTH; S63 obtains the minimum deviation value DabsTH min ; S64 judging the minimum deviation value DabsTH min Whether it is less than or equal to the deviation threshold Dev thr , S7 DabsTH min If it is less than or equal to the Devthr, obtain the second pipe wall thickness value, a tot...

Embodiment 3

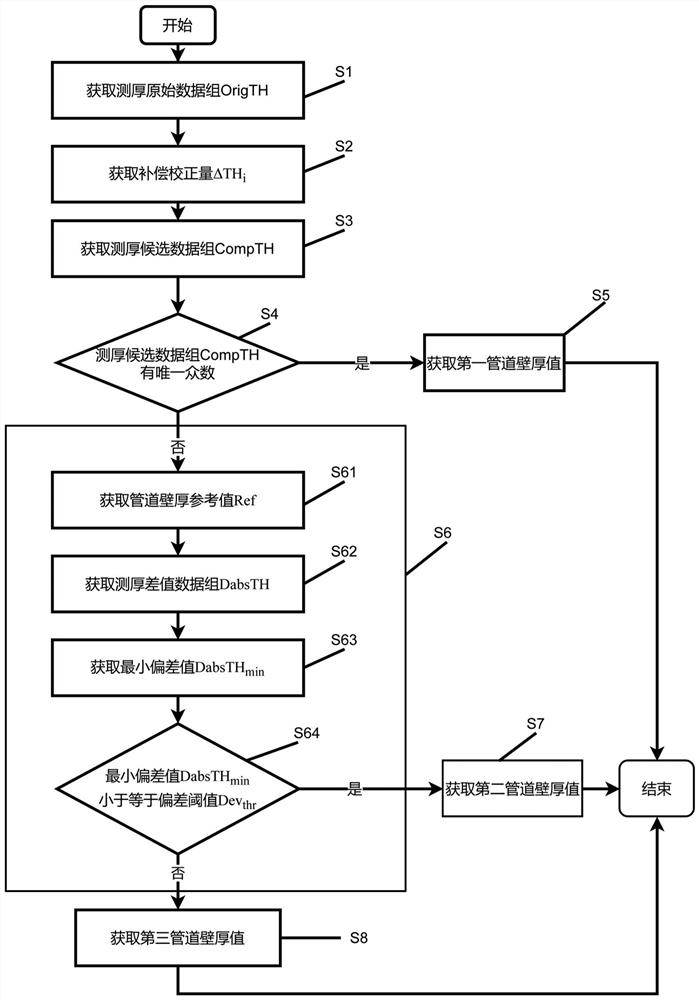

[0039] In this exemplary embodiment, if image 3 As shown, the pipeline wall thickness acquisition method includes S1 to obtain the original thickness measurement data set OrigTH, S2 to obtain the compensation correction amount ΔTH i , S3 obtains the thickness measurement candidate data set CompTH, S4 judges whether the thickness measurement candidate data set CompTH has a unique mode, S5 the thickness measurement candidate data set CompTH has a unique mode, obtains the first pipeline wall thickness value, S6 thickness measurement candidate data set CompTH has no unique mode: S61 obtains the pipe wall thickness reference value Ref; S62 obtains the thickness measurement difference data set DabsTH; S63 obtains the minimum deviation value DabsTH min ; S64 judging the minimum deviation value DabsTH min Whether it is less than or equal to the deviation threshold Dev thr , S7 DabsTH min Less than or equal to the Devthr, get the second pipe wall thickness value, S8 DabsTH min If ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com