Automatic detection method and system for chip surface defects and electronic equipment

An automatic detection and surface defect technology, which is applied in the direction of optical test defect/defect, measurement device, image data processing, etc., can solve the problems of low accuracy, low detection precision, slow detection speed, etc., and achieve the effect of improving the detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

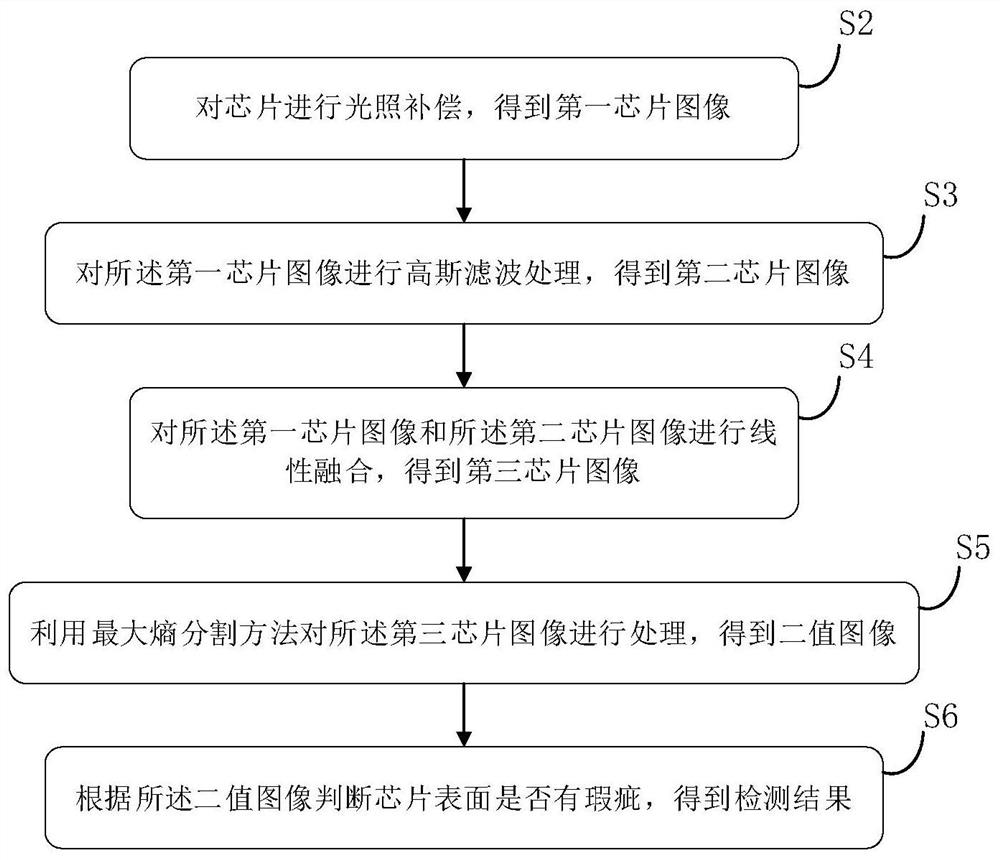

[0060] Such as figure 1 Shown, the embodiment of the automatic detection method of a kind of chip surface blemish of the present invention, comprises the following steps:

[0061] S2. Perform light compensation on the chip image to obtain the first chip image;

[0062] S3. Perform Gaussian filter processing on the first chip image to obtain a second chip image;

[0063] S4. Perform linear fusion on the first chip image and the second chip image to obtain a third chip image;

[0064] S5. Using a maximum entropy segmentation method to process the image of the third chip to obtain a binary image;

[0065] S6. Determine whether there is a defect on the surface of the chip according to the binary image, and obtain a detection result.

[0066] Illumination compensation for the image can correct the uneven illumination p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com