Semiconductor wafer integral cleaning equipment

A technology for cleaning equipment and semiconductors, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as long working hours, heavy physical exertion of workers, and wafer damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

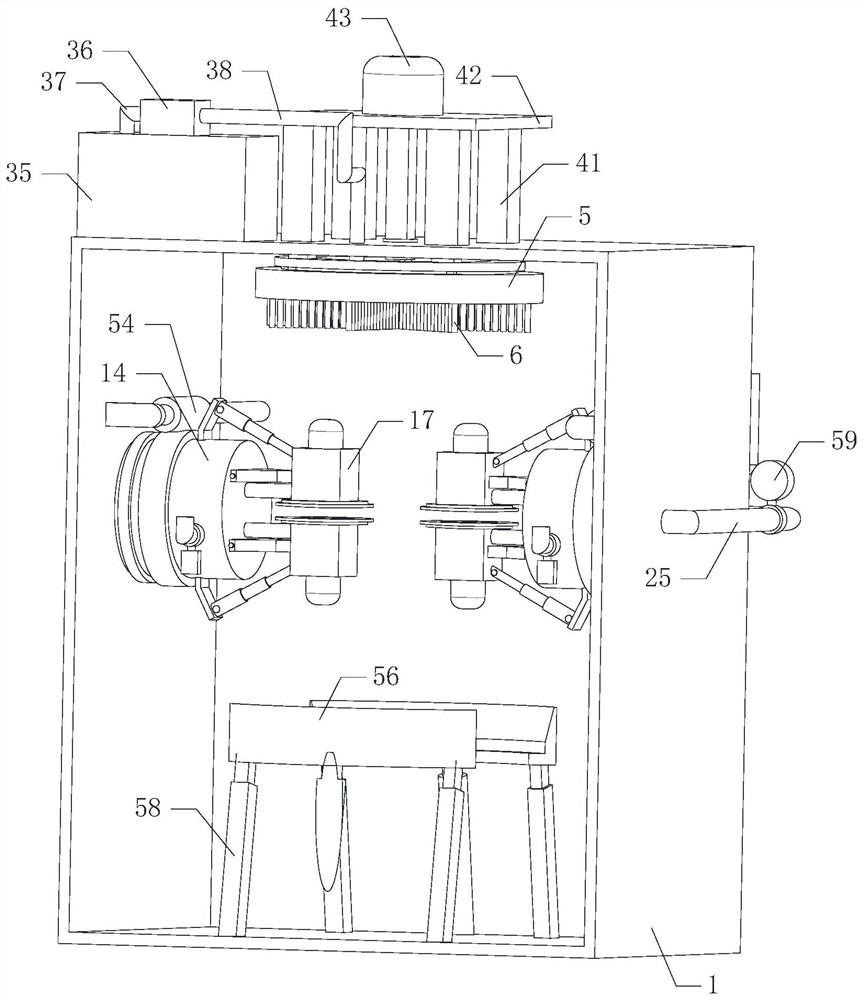

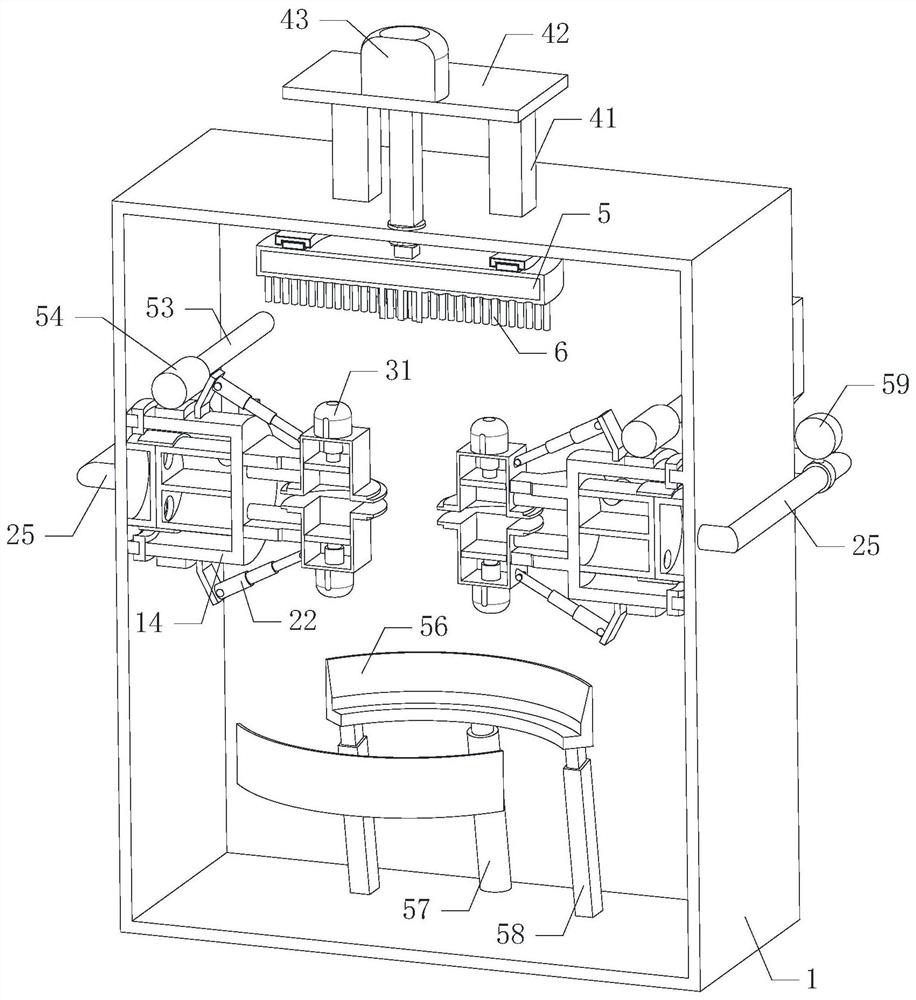

[0022] Such as Figure 1 to Figure 7 As shown, a kind of overall semiconductor wafer cleaning equipment of the present invention, when it is working, the operating mode of the turning device is that the central control box 4 controls to open the power device, and the power device drives the worm wheel 15 on the turning device to rotate, and the worm wheel 15 drives The rotating bucket 14 rotates, and the rotating bucket 14 drives the annular chute 13 to slide on the annular guide rail 12. When the second ventilation hole 11 is turned over to the upper side of the second ventilation hole 11, the second ventilation hole 11 on the original upper side is turned over to the po...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap