Passive micro light-emitting diode matrix device with uniform luminance

A micro-light-emitting diode technology with uniform brightness, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as difficulty in uniform brightness and uneven brightness, and achieve the effect of improving brightness uniformity and compensating series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

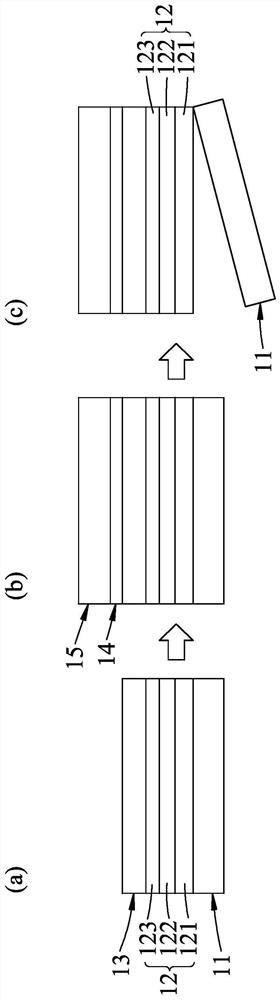

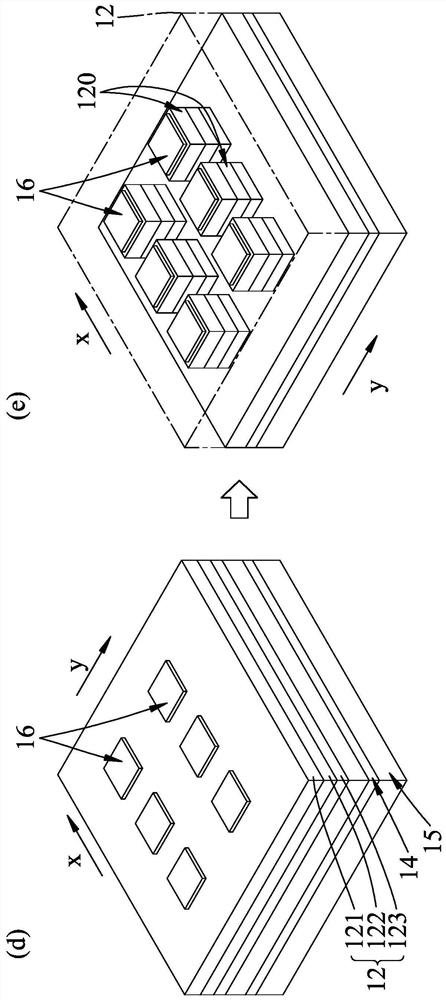

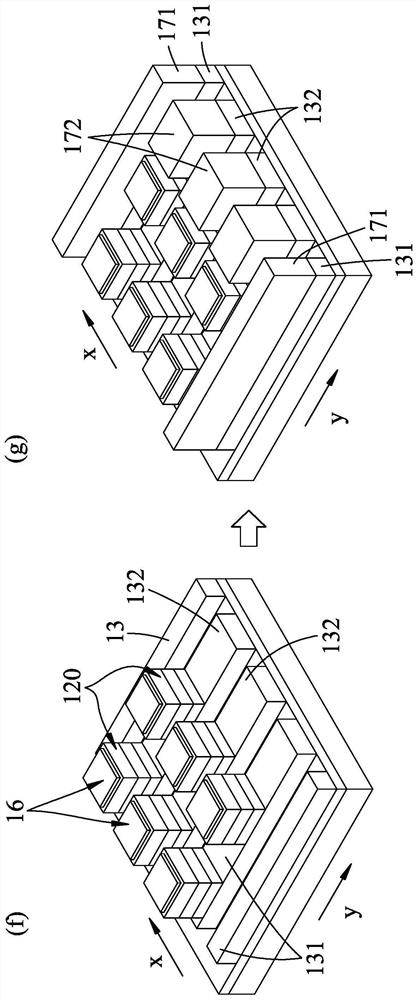

Method used

Image

Examples

Embodiment Construction

[0061] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

[0062] refer to Figure 7 to Figure 11 A first embodiment of the passive micro-light emitting diode array device with uniform brightness of the present invention is used for electrical bonding to a printed circuit board (such as a flexible printed circuit board) that is bonded to a driver chip (not shown) 9 , which includes a micro light emitting diode array 2 and an external circuit component 3 .

[0063] Such as Figure 7 and Figure 8 As shown, the micro light emitting diode array 2 of the first embodiment of the present invention is essentially composed of a substrate 21 having an array setting surface 211, a plurality of micro light emitting diode arrays 22 and an insulating layer 23 for the array; wherein, the The substrate 21 is a double-sided polished sapphire substrate.

[0064] The micro-light emitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com