Glove taking-off device

A technology for picking up devices and gloves, which is applied in the field of glove production equipment, can solve the problems that the gripping action of the gripper is difficult to accurately control, the working stability of the picking device is poor, and the production and use of users are affected, and the control is convenient and the work is stable. Good, stable stroke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

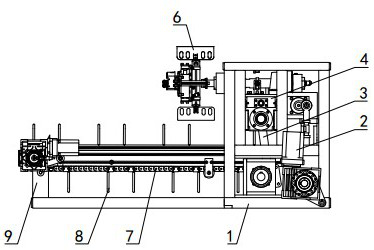

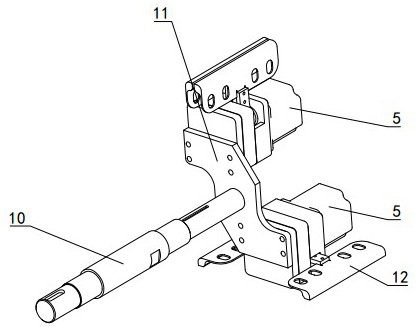

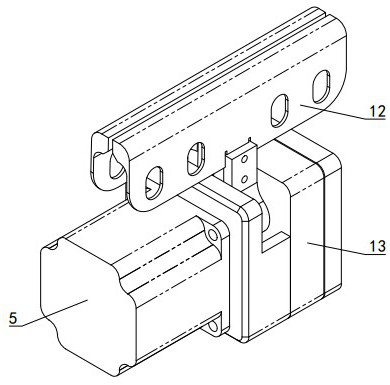

[0031] Such as figure 1 As shown: the rotating device is slidably installed on the frame 1, and the lifting device is arranged on the frame 1 on the lower side of the rotating device. Multiple, thereby improving the extraction efficiency of the equipment.

[0032] The lower side of the clamping device is provided with a conveying device 7, and the conveying device 7 is arranged horizontally. The lower side of one end of the conveying device 7 away from the frame 1 is provided with a support profile 9, and the other end extends into the frame 1 and is arranged on the clamping The lower side of the device, the upper side of the delivery device 7 near the end of the frame 1 is provided with a lift cylinder, the lift cylinder is installed on the frame 1 and vertically arranged, the piston rod of the lift cylinder is connected with the delivery device 7, and drives its Swing, so that the height of the conveying device 7 can be adjusted according to the thickness of the glove stack...

Embodiment 2

[0045] Such as Figure 7 As shown: the difference between embodiment 2 and embodiment 1 is that the conveying device 7 is a conveying belt 23, and a synchronous belt is fixed inside the conveying belt 23, and the conveying motor 17 drives the synchronous belt to rotate, thereby realizing the rotation of the conveying belt 23, and the baffle plate 8. It can effectively ensure that piles of gloves will not be overturned, and the overall conveyor belt 23 will not be misplaced and ensure that the gloves will not be polluted by accumulated dust during transportation.

[0046] Such as Figure 8 As shown: each lifting frame 18 is only provided with a hand model seat, the lower side of the lifting frame 18 is provided with a vertical mounting rod, and the hand model mounting plate 19 is coaxial and rotatably mounted on the mounting rod, and the hand model mounting plate 19 is slidingly connected with the installation rod, the diameter of the lower end of the installation rod is large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com