Large-scale road maintenance equipment for detecting looseness of rail fastener and corresponding detection method

A technology for track fasteners and large-scale road maintenance. It is applied in the direction of railway auxiliary equipment, measuring devices, and the use of re-radiation. It can solve the problems of image quality impact, infrared sensitive marks not lasting, and inability to identify the looseness of fasteners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

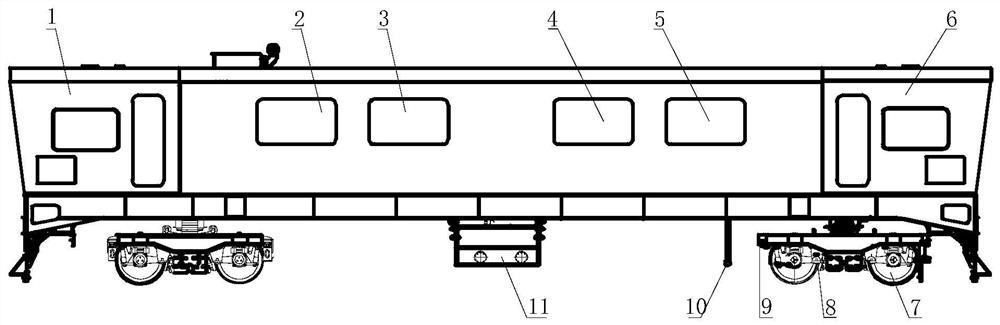

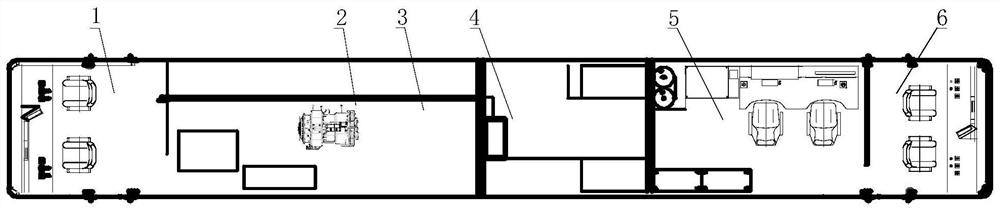

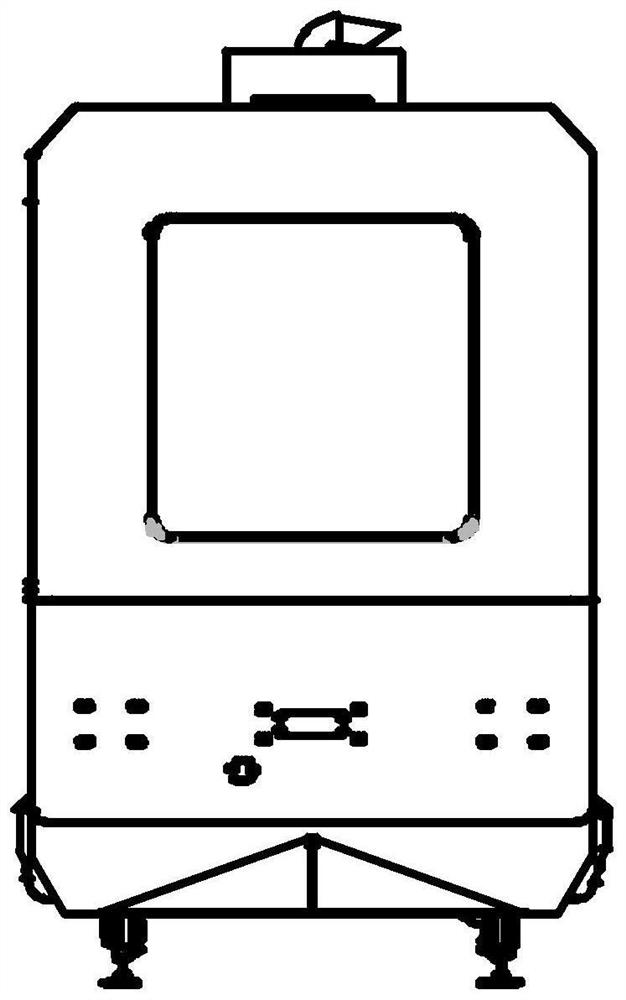

[0047] Embodiment 1.1: The large-scale road maintenance equipment used to detect the loosening of track fasteners includes a vehicle frame, and a running mechanism 7 is arranged below the vehicle frame. The running mechanism 7 includes a braking system 8, and a rail inspection beam is also provided on the running mechanism 7 9. The lower part of the frame includes the fuel tank 11, the upper part of the frame includes the front driver's cab 1 and the rear driver's cab 6, and the space between the front driver's cab 1 and the rear driver's cab 6 includes the power room 2, auxiliary generator 3, electrical system 4 and fasteners The loose detection room 5 includes a high-definition camera 10 in front of the rail inspection beam 9 at the lower part of the vehicle frame.

[0048] The fastener loose detection room 5 includes a laser range finder, a vibration compensation device, a microcomputer control system, a video recognition system and a positioning synchronization system. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com