Living body cold chain transportation equipment

A technology of cold chain transportation and equipment, which is applied in the direction of transportation and packaging, packaging objects under special gas conditions, shock-sensitive objects, etc., and can solve problems such as low water and oxygen content and temperature changes in transportation boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

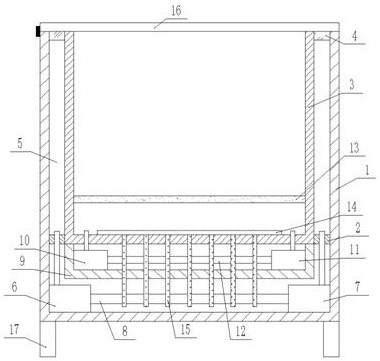

[0023] Example 1 as figure 1 As shown, this living body cold chain transport equipment includes a housing 1, the inner wall of the housing 1 is fixedly connected with a connecting plate 2, the inner wall of the connecting plate 2 is fixedly connected with a transport box 3, and the connecting plate shell 1 and the transport box 3 is fixedly connected with an annular water baffle 4, and an annular water tank 5 is formed between the annular water baffle 4, the transport box 3, the connecting plate 2 and the housing 1, and the annular water tank 5 is filled with cooling water. The inside of the housing 1 The wall is fixedly connected with a cooling water tank 6 and a centrifugal pump 7, and the water outlet of the cooling water tank 6 is fixedly connected to the water inlet of the centrifugal pump 7 through a conduit 8, and the water inlet of the cooling water tank 6 and the water outlet of the centrifugal pump 7 both pass through the side of the connecting plate The wall is fixe...

Embodiment 2

[0024] Embodiment 2 is on the basis of embodiment 1 such as figure 1 As shown, the inner wall of the transport box 3 is fixedly connected with a filter screen 13 , which can reduce impurities from falling into the water inlet of the water oxygen machine 10 .

Embodiment 3

[0025] Embodiment 3 is such as on the basis of embodiment 1 figure 1 As shown, the inner wall of the bottom end of the transport box 3 is fixedly connected with a heat conduction plate 14, and the lower end of the heat conduction plate 14 is fixedly connected with a plurality of heat conduction fins 15 penetrating through the side wall of the transport case 3, and a plurality of heat conduction fins 15 penetrate the side of the U-shaped plate 9 The walls are all sleeved on the tube walls of the conduit 8 and the circulation tube 12, which can facilitate cold and heat exchange and improve the cooling effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com