Feeding mechanism for batten machining

A wood strip and feeding technology, which is applied to wood processing equipment, wood bending, manufacturing tools, etc., can solve the problems of disorderly, uneven length of wood strips, etc., and achieve the goal of reducing production costs, liberating manpower, and realizing automatic operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

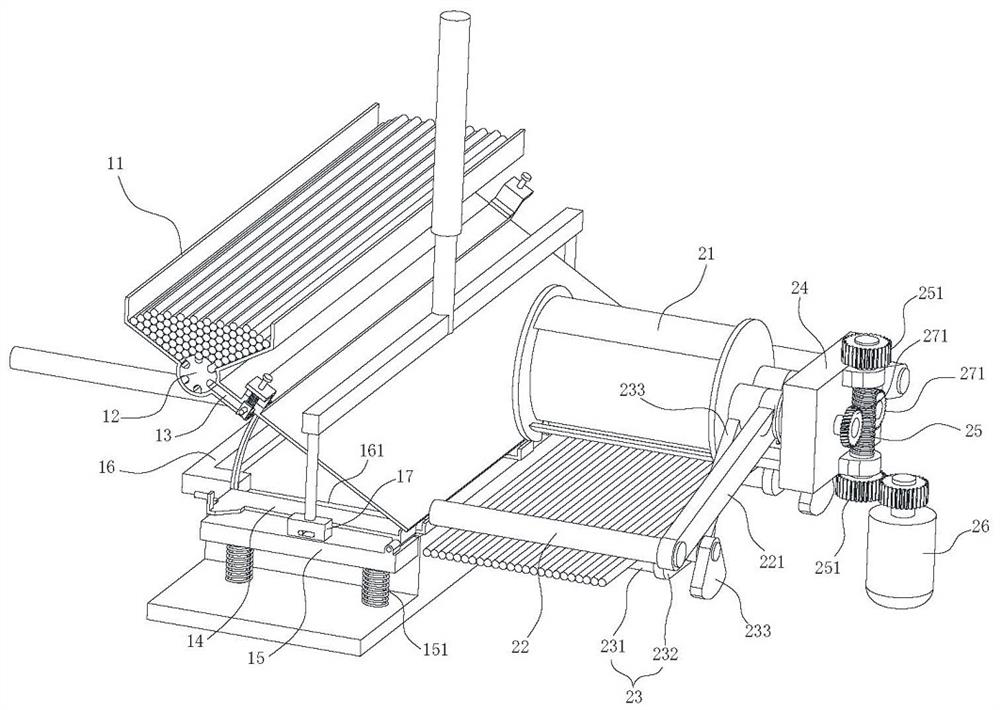

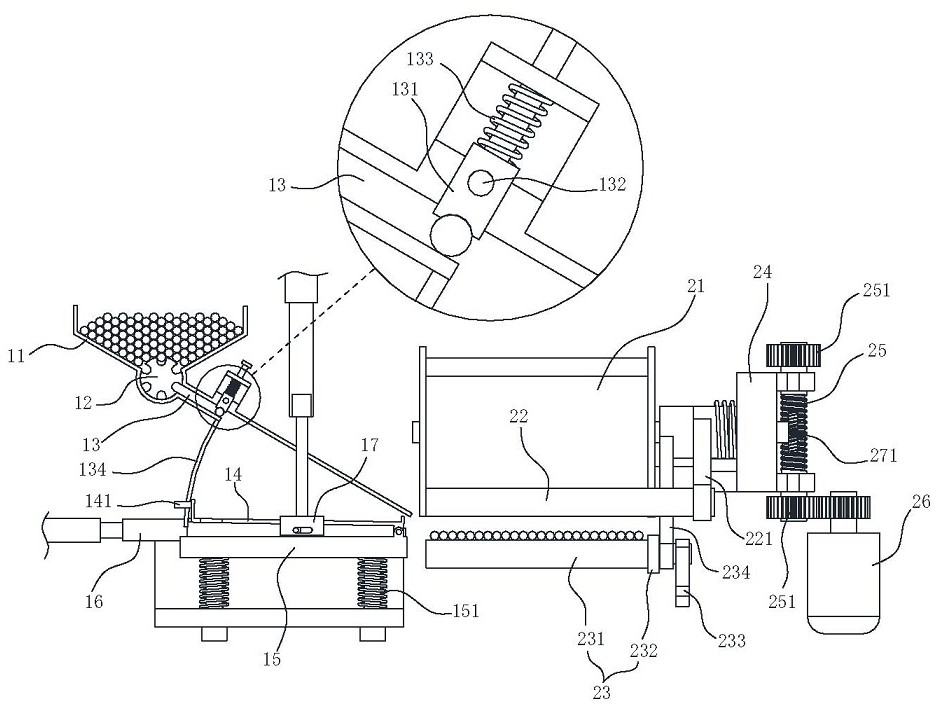

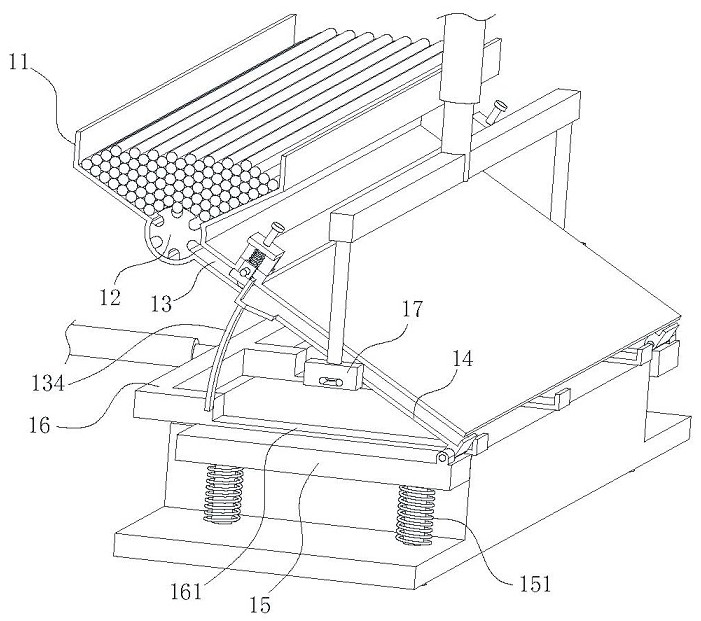

[0028] like figure 1 , 2 As shown, a kind of material retrieving device that is used for the bending and forming of wood strips comprises feeding mechanism 10 and bending manipulator 20, and described bending manipulator 20 is installed on the conveying device 50, and feeding mechanism 10 is positioned at bending manipulator 20 along with conveying device 50 Beside the motion path during motion; as in Figure 1-4 As shown, the feeding mechanism 10 includes a material storage tank 11, a discharge unit, a transfer unit and a push unit. The discharge unit is connected to the discharge port, and the discharge unit is assembled so that the wood strip raw materials can be discharged from the discharge port one by one and arranged in a parallel row. The transfer unit is used to arrange the discharge unit The wooden strip raw material is transferred to the pushing unit, and the pushing unit is used to push the arranged wooden strip raw material to the bending manipulator 20; the fee...

Embodiment 2

[0041] A method for pretreatment of wood strips using the reclaiming device described in embodiment 1, comprising the steps of:

[0042] Step 1: Use ring cutting equipment to cut the surface of the wooden strips, and cut the wooden strips into straight rods with equal diameters;

[0043] Step 2: Trim both ends of the wooden strips to make the lengths of each wooden strip consistent;

[0044] Step 3: Clean the floating dust on the surface of the wood strips and dry them naturally;

[0045] Step 4: Arrange multiple wooden strips in parallel in a row, and transfer the whole row of wooden strips to the bending forming equipment;

[0046] In the step 4, the wood strips are discharged and transferred by using the feeding mechanism 10, the feeding mechanism 10 includes a storage tank 11, a discharge unit, a transfer unit and a pushing unit, and the storage tank 11 is used for Straight wooden strip raw materials are stored, the bottom of the storage tank 11 is provided with a discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com