A kind of preparation method of woven-like gabardine warp-knitted twill fabric

A technology of gabardine and imitation woven weaving, which is applied in warp knitting, knitting, textiles and papermaking, etc. It can solve the problems of lack of fabrics, etc., and achieve the effects of clear lines, moisture absorption, perspiration, air permeability, and good moisture absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

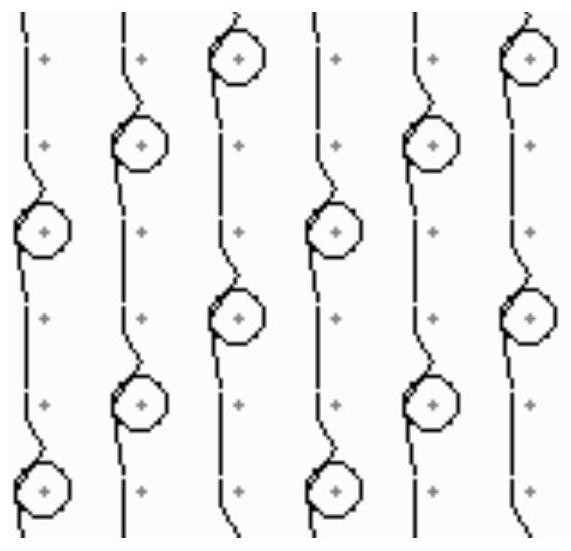

[0052] Embodiment 1: One up and two down type imitation woven gabardine

[0053] A warp-knitted elastic twill fabric imitating woven gabardine spun yarn based on knitting chain missing cushion weave and heavy warp knitting chain weave, which is composed of the following mass percentage components: 60S / 2 cotton strands are 5.3%, 40 / 75 Polyester coated ammonia yarn is 94.7%. The texture of the woven gabardine-like fabric is formed through the yarn threading method of the missing pad structure and the distribution of the coil extension lines, and the reverse side of the process is used as the front of the fabric for wearing.

[0054] The preparation process of the fabric comprises the following steps:

[0055] 1. Preparation process

[0056] Use 60S / 2 cotton strands, 32S wool, 32S cotton-polyester blended yarn, and 40 / 75 polyester-coated ammonia yarn;

[0057] 2. Warping process

[0058] Temperature and humidity at the warping site: temperature 25±1°C, relative humidity 65±5%...

Embodiment 2

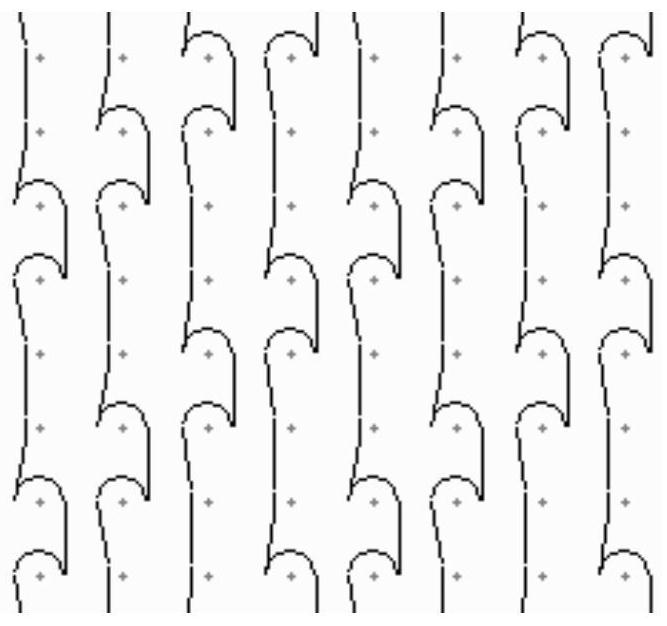

[0080] Embodiment 2: two-up and two-down imitation woven gabardine

[0081] A kind of imitation woven gabardine spun yarn warp-knitted fabric based on knitting chain missing pad weave and heavy warp knitting chain weave, composed of the following mass percentage components: 32S wool is 6.6%, 40 / 75 polyester-coated ammonia yarn is 93.4% %. The texture of the woven gabardine-like fabric is formed through the yarn threading method of the missing pad structure and the distribution of the coil extension lines, and the reverse side of the process is used as the front of the fabric for wearing.

[0082] The preparation process of the fabric comprises the following steps:

[0083] 1. Preparation process

[0084] Use 60S / 2 cotton strands, 32S wool, 32S cotton-polyester blended yarn, and 40 / 75 polyester-coated ammonia yarn;

[0085] 2. Warping process

[0086] Temperature and humidity at the warping site: temperature 25±1°C, relative humidity 65±5%, high and stable temperature and h...

Embodiment 3

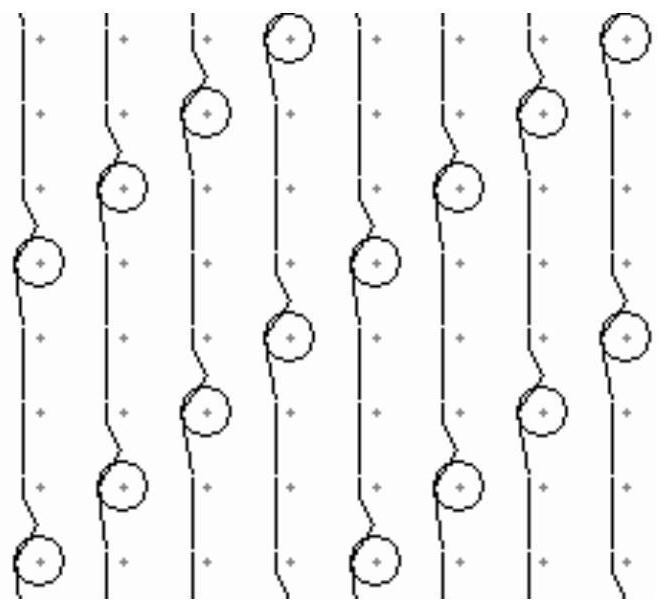

[0109] Embodiment 3: One-up and three-down imitation woven gabardine

[0110] A kind of woven-like gabardine spun yarn warp-knitted fabric based on knitting chain missing pad weave and heavy warp knitting chain weave, which is composed of the following mass percentage components: 11.9% of 32S cotton-polyester blended yarn, 40 / 75 polyester bag Ammonia yarn is 88.1%. This fabric forms the twill pattern effect of the imitation woven gabardine fabric through the yarn threading method of the missing pad structure and the distribution of the coil extension lines, and the reverse side of the process is used as the front side of the fabric.

[0111] The preparation process of the fabric is

[0112] The preparation process of the fabric is as follows: the specific process of each process is as follows: including single comb structure selection, preparation process, warping, weaving, washing, setting and drying.

[0113] 1. Preparation process

[0114] Use 60S / 2 cotton strands, 32S w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com