Stokehole fine feeding control method for melting device

A control method and melting device technology, applied in the direction of combustion method, incinerator, fuel supply, etc., can solve problems such as insufficient melting, reduced waste heat treatment effect, poor stability, etc., to avoid material accumulation or empty burning, The effect of good waste heat treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

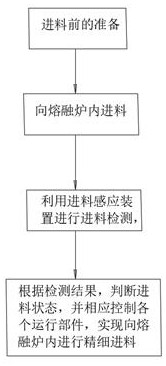

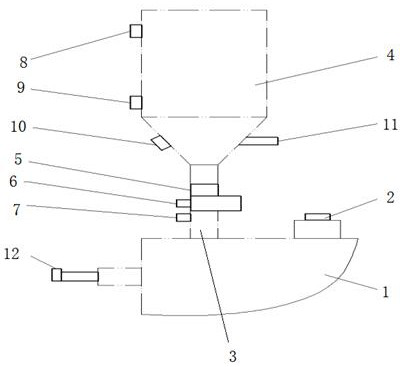

[0022]Example: A method for fine feeding control in front of the furnace for melting device, such asfigure 1 As shown, including the following steps:

[0023]Step S1: Carry out the equipment work in the early stage of feeding to ensure that all operating parts can work normally, and then fully open the flapper valve at the bottom of the silo;

[0024]Step S2: Turn on the anti-rotation low level switch on the silo, and feed the material into the silo, then start the rotary valve feeder and the stirring device on the melting furnace at the same time, and install the set value in the melting furnace. Feeding; In the step S2, when the material in the silo reaches the high material level, the anti-rotating low material level switch on the silo is turned off, and the silo anti-rotating high material level switch is turned on to stop feeding into the silo .

[0025]Step S3: real-time detection of the material passing through the feed port by the feed sensing device;

[0026]Step S4: Judging the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com