Water level sensor

A water level sensor and intermediate position technology, applied in the field of sensors, can solve the problems of low flexibility in sensor disassembly and assembly, the inability of the water level sensor to ensure the level of the detection surface, and the non-adjustable wiring tightness, etc., to achieve good sealing, The effect of avoiding short circuit and improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

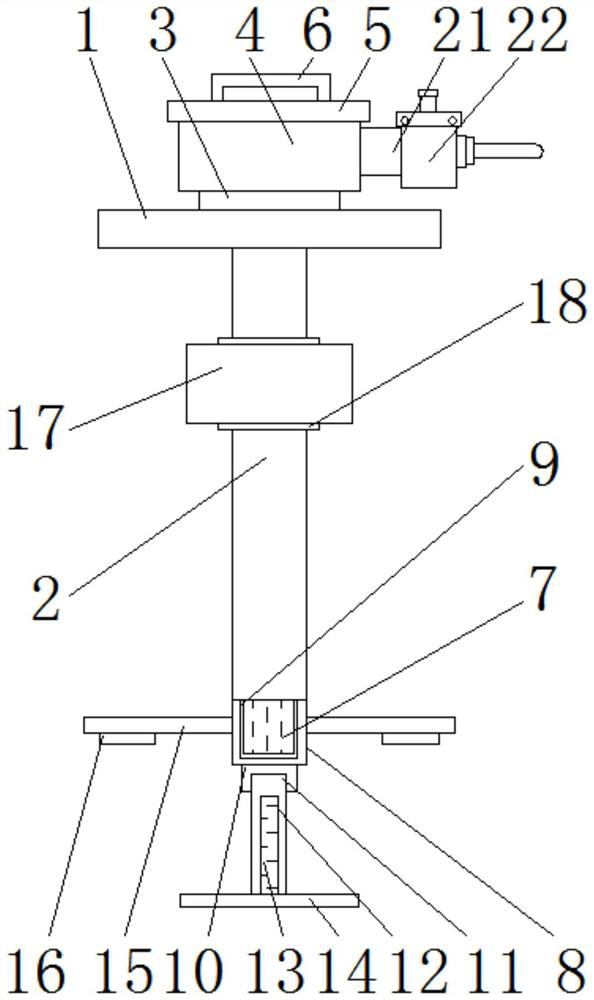

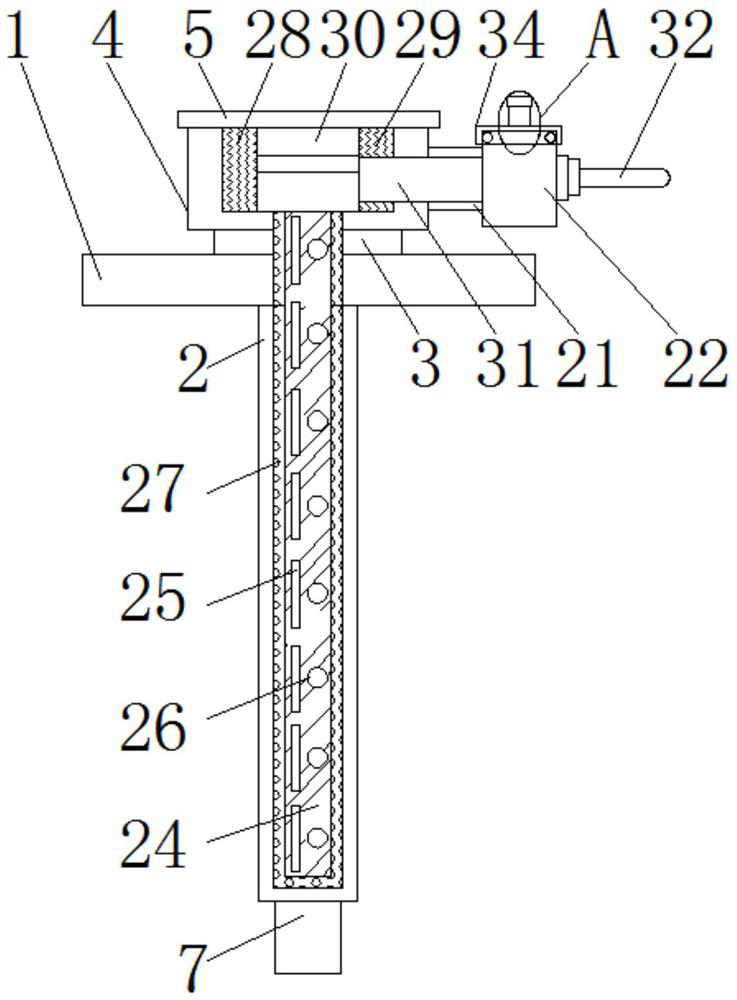

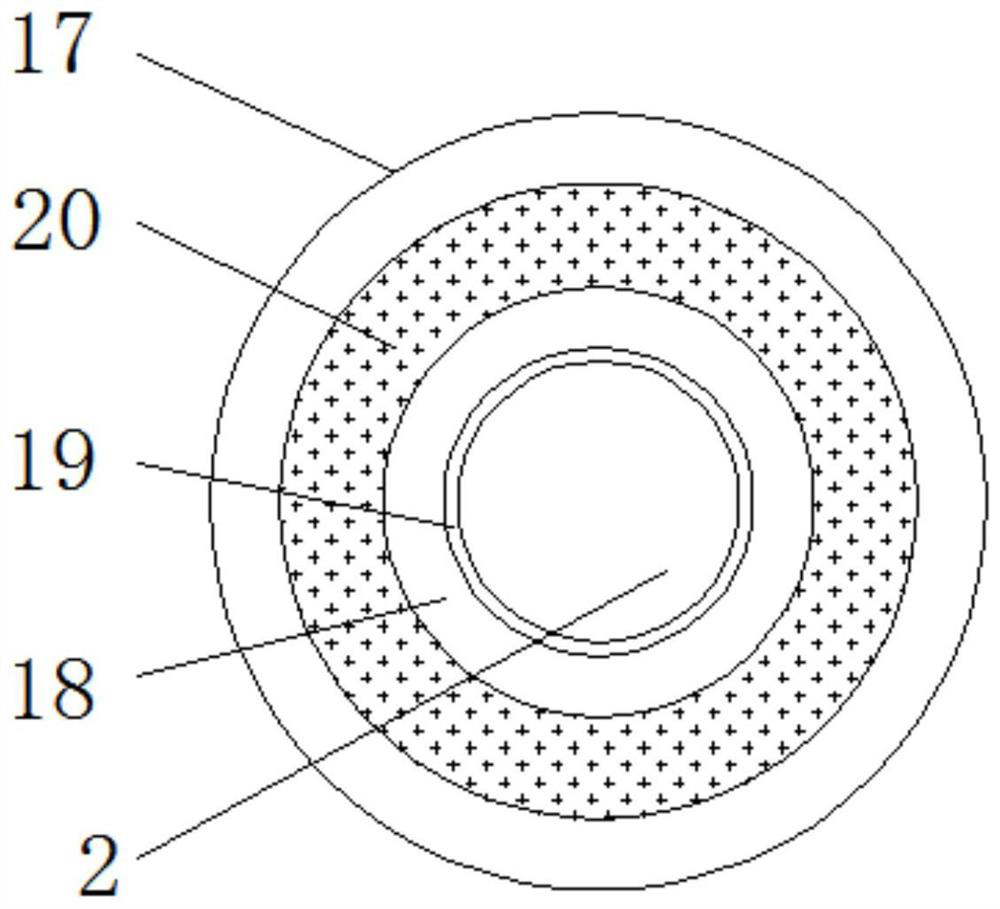

[0031] refer to Figure 1-6, a water level sensor, comprising a base plate 1, a sleeve rod 2 is vertically welded between the middle positions of the upper and lower surfaces of the base plate 1, a gasket 3 is fixedly installed at the middle position of the upper surface of the base plate 1, and the upper surface of the gasket 3 is welded with a fixed Block 4, the lower surface of the sleeve rod 2 is welded with a clamp column 7, and the sleeve rod 2 is movably installed with a column sleeve 8 through the clamp column 7, and the lower surface of the column sleeve 8 is welded with an inner threaded sleeve 10, and the column sleeve 8 passes through the inner screw The sleeve 10 is movably connected with a support rod 11, and a bump 21 is welded on one side of the outer wall of the fixed block 4, and the side wall of the bump 21 away from the fixed block 4 is fixedly installed with a wiring cover 22, and the wiring cover 22 is far away from the bump 21 Three sets of wire sleeves ...

Embodiment 2

[0034] refer to Figure 2-7 , a water level sensor, comprising a base plate 1, a sleeve rod 2 is vertically welded between the middle positions of the upper and lower surfaces of the base plate 1, a gasket 3 is fixedly installed at the middle position of the upper surface of the base plate 1, and the upper surface of the gasket 3 is welded with a fixed Block 4, the lower surface of the sleeve rod 2 is welded with a clamp column 7, and the sleeve rod 2 is movably installed with a column sleeve 8 through the clamp column 7, and the lower surface of the column sleeve 8 is welded with an inner threaded sleeve 10, and the column sleeve 8 passes through the inner screw The sleeve 10 is movably connected with a support rod 11, and a bump 21 is welded on one side of the outer wall of the fixed block 4, and the side wall of the bump 21 away from the fixed block 4 is fixedly installed with a wiring cover 22, and the wiring cover 22 is far away from the bump 21 Three sets of wire sleeves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com