Flat plate type laser beam splitting film based on composite material and design method of flat plate type laser beam splitting film

A technology of composite materials and design methods, which is applied in optics, optical components, instruments, etc., can solve problems such as increasing the difficulty of film thickness, and achieve the effect of increasing laser damage threshold, high refractive index, and reducing film thickness monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The present invention will be further described below in conjunction with the embodiments and drawings.

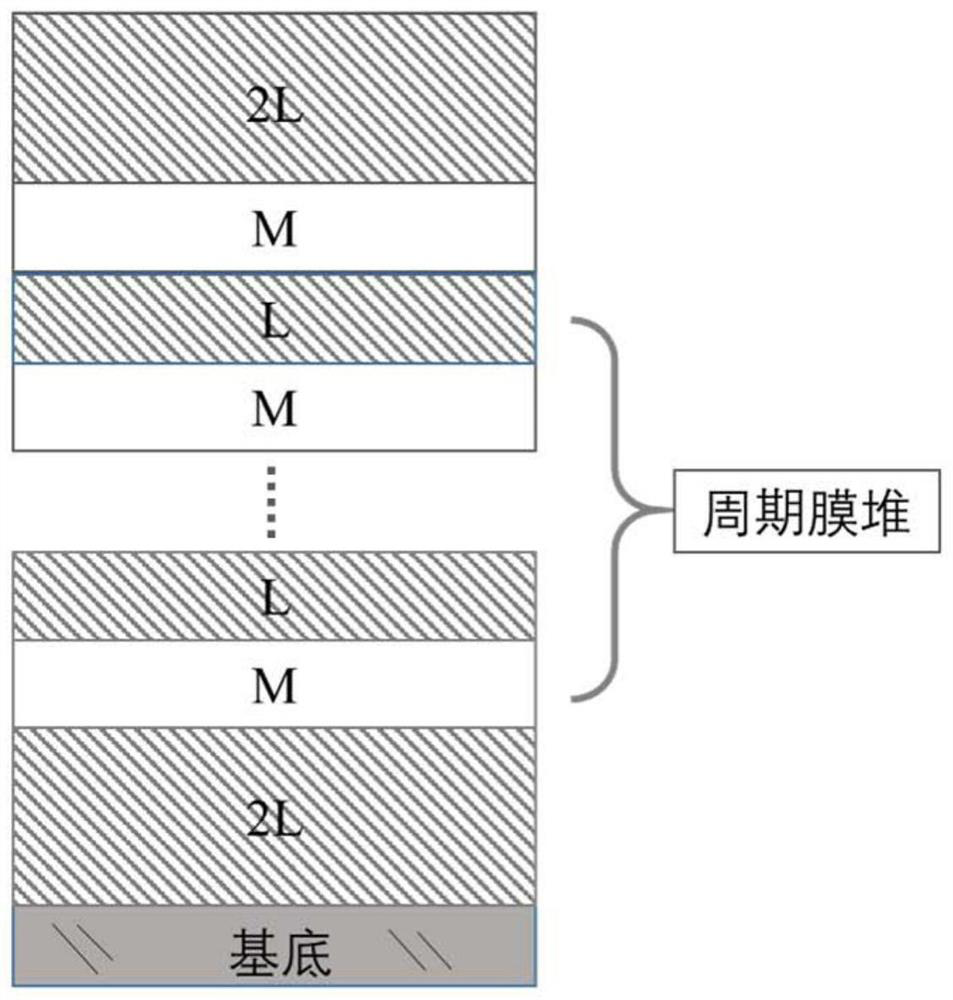

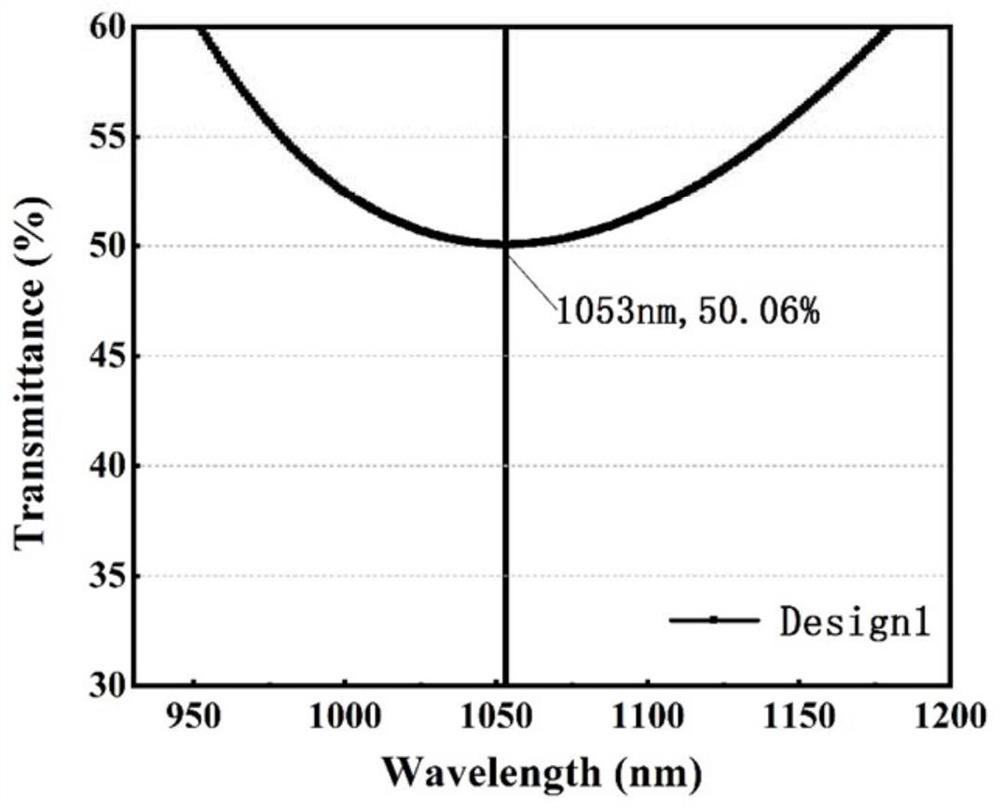

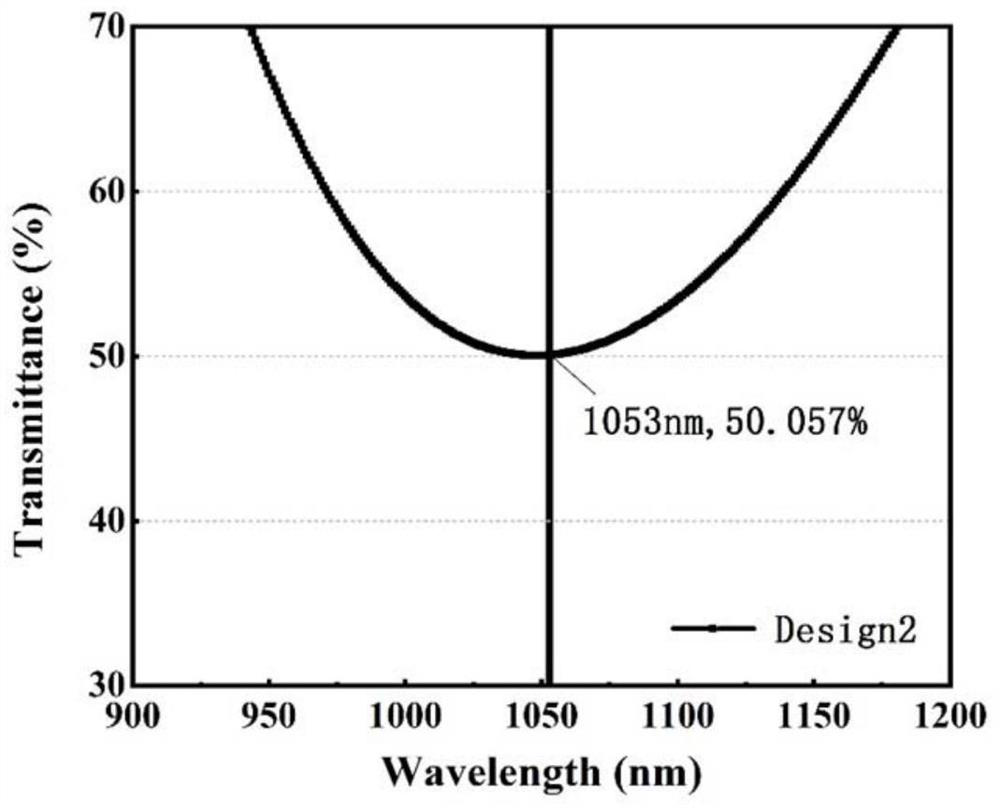

[0042]Taking a 45-degree incident, s-polarization component, and achieving a transmittance of 50±1% at 1053 nm as an example, a flat-plate laser beam splitting film based on a composite material and a design method thereof are described in the present invention.

[0043]The design method specifically includes the following steps:

[0044]1) Parameter setting: design transmittance value T of laser beam splitting filmD=50%, beam incident angle θ=45°, incident beam is s-polarized component, at the center wavelength of 1053nm, the refractive index of the quartz substrate is nS= 1.4378, HfO2Refractive index of material nA= 1.9088, Al2O3Refractive index of material nB= 1.5910, SiO2Refractive index of material nC=1.4212, the initial film structure is S|dL(HL)gHmL|A, where S represents a substrate, H represents a high refractive index film with an optical thickness of λ / 4 (λ refers to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical band gap | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com