SOI-based LDMOS device based on flexible substrate and manufacturing method thereof

A flexible substrate and device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of low mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with accompanying drawing, further describe the present invention in detail through embodiment.

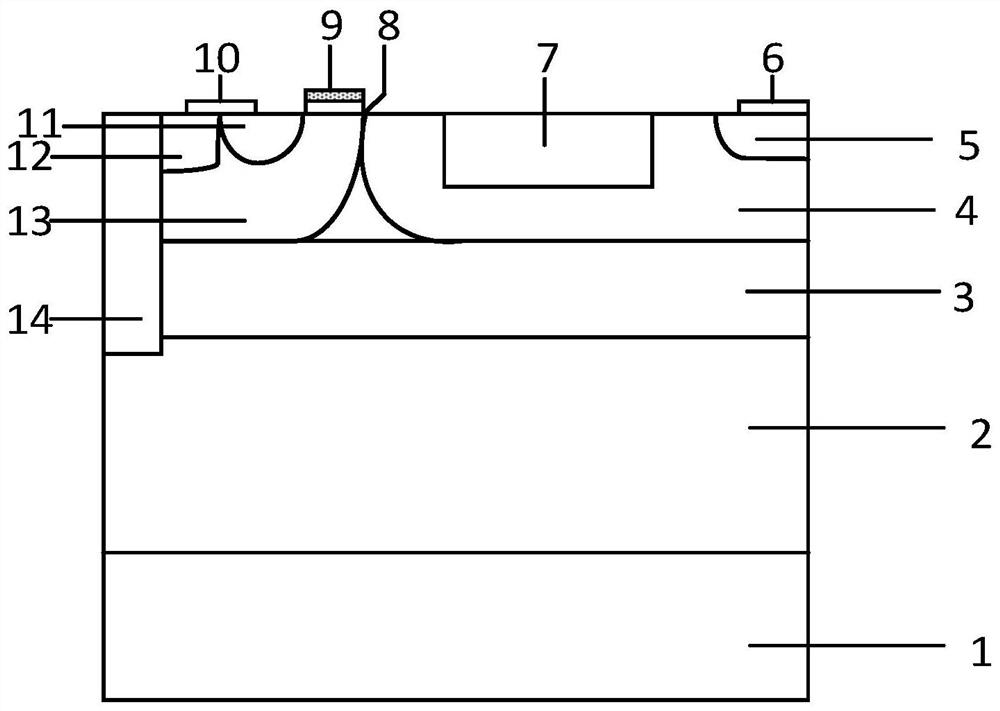

[0054] Such as figure 1 As shown, an SOI (Silicon-On-Insulator)-based lateral double-diffused metal-oxide-semiconductor field effect transistor (LDMOS) applied to a flexible electronic system has a structure of:

[0055] Substrate 1 of flexible material; PDMS, PET, PI, PEN and other flexible materials can be used, and the substrate thickness of the flexible material is 200-500 μm;

[0056] The P-type silicon layer 2 located on the surface of the substrate has a thickness of 2-10 μm;

[0057] The SOI base 3 located on the surface of the P-type silicon layer has a thickness of 1-3 μm;

[0058] The base region 13 and the drift region 4 formed by the epitaxial layer on the SOI base are relatively on the left and right sides respectively, with a thickness of 1-2 μm;

[0059] The source region formed on top of the base region is composed of P + District 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com