Product Edge Defect Detection Method

A technology of edge defect and detection method, which is applied in image analysis, image enhancement, instruments, etc., can solve the problems of weak generality in the research of edge defect detection algorithm, inapplicability of stretching edge detection, etc., and achieve fast calculation speed and detection high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention is described in detail below in conjunction with embodiment. In order to make the purpose, technical solutions and advantages of the present invention clearer and clearer, the present invention will be further described in detail below, but the present invention is not limited to these examples.

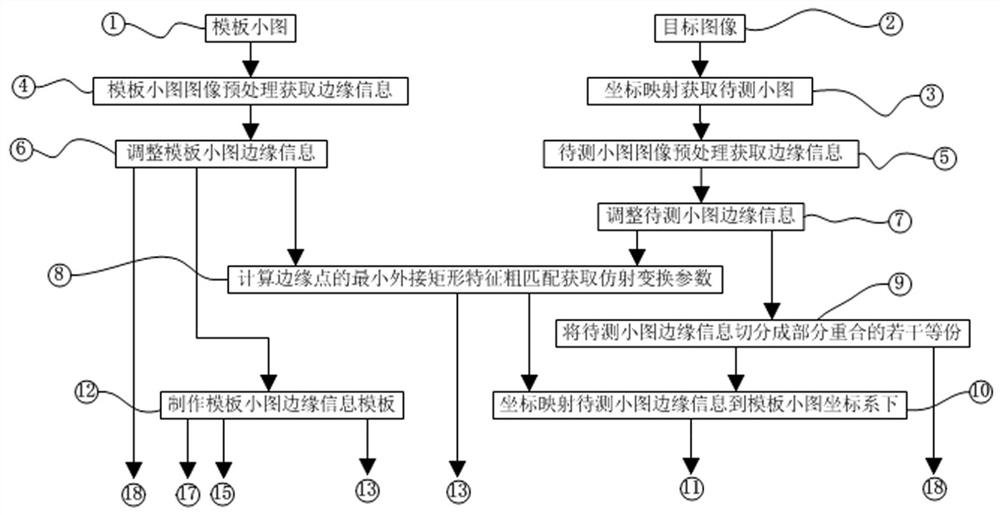

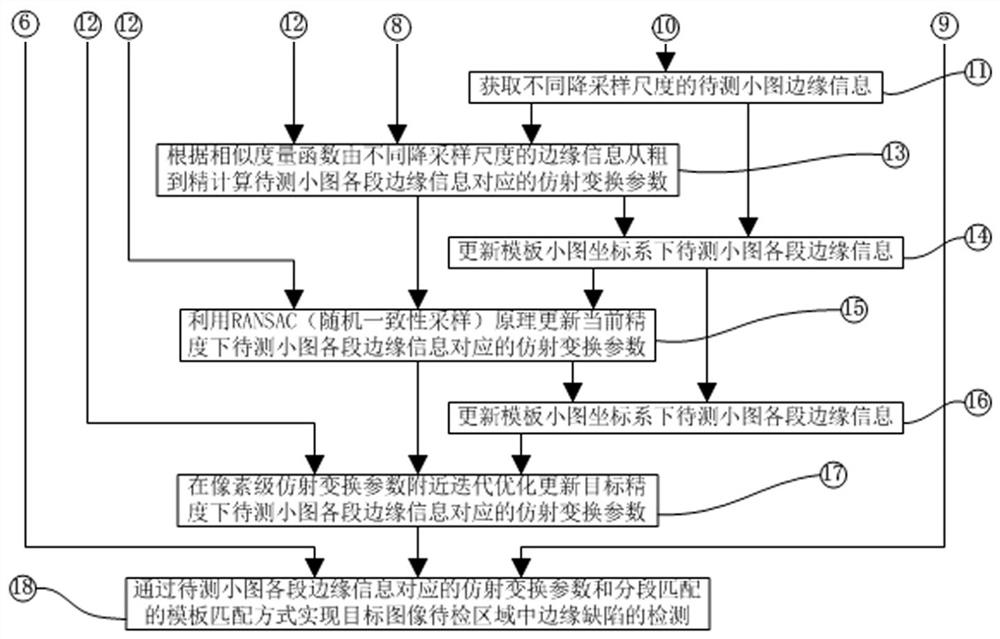

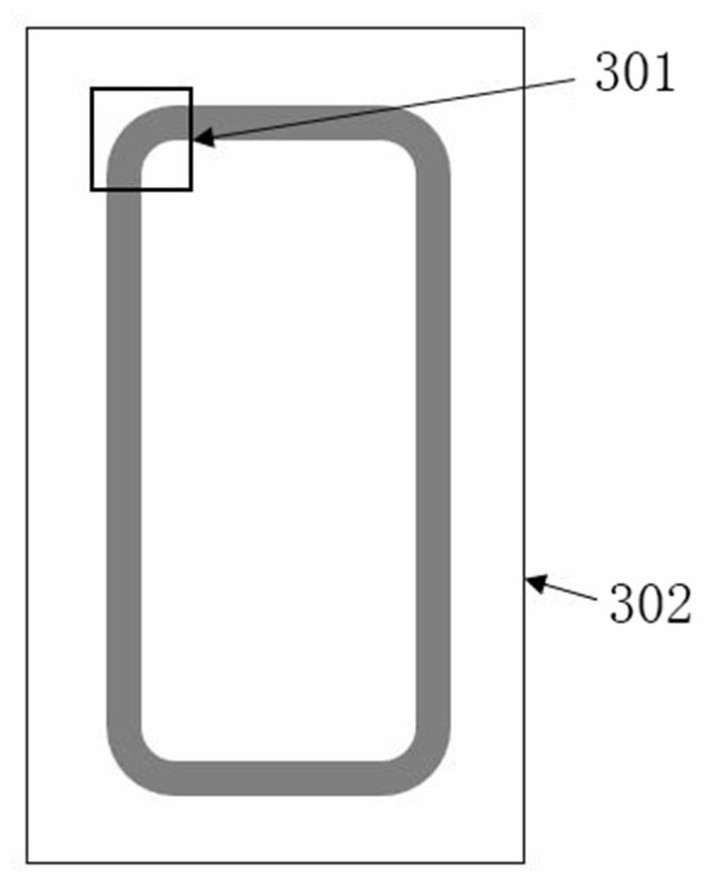

[0052] The invention provides a fast stretch-resistant edge defect detection method based on template matching. This method is based on the image edge information, by obtaining the edge information of the template small image to make an edge information template, using the coordinate transformation to determine the ROI of the target image to be inspected to obtain the small image to be tested, and by obtaining the edge information of the small image to be tested to make different downsampling scales. Measure the edge information, obtain the affine transformation parameters according to the rough matching of the minimum circumscribed rectangle features of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com