On-line system and method for recovering hole sealing agent and utilizing reclaimed water through single nickel salt coloring

A technology of sealing agent and nickel salt, which is applied in chemical instruments and methods, applications, water pollutants, etc., can solve the problems of large mixed waste residues, great environmental hazards, and increased cell voltage, and achieves resource recycling and reduction. The effect of industrial hazardous waste discharge and environmental protection cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

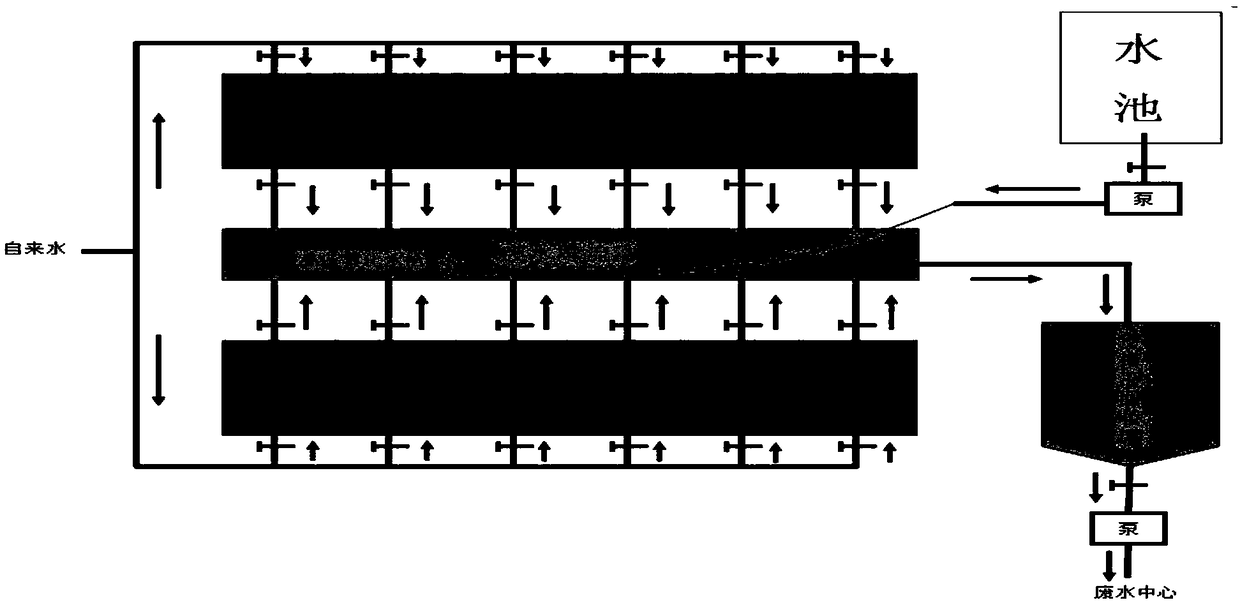

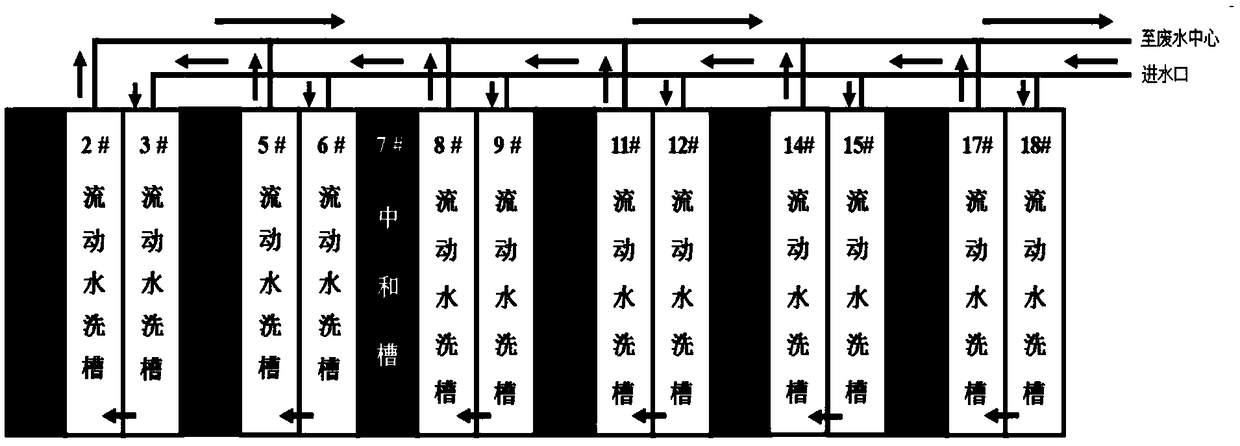

[0210] Embodiment 1 (nickel-containing wastewater retention system operation)

[0211] Operation process of nickel-containing waste water interception system: Open valve 14, clean tap water enters from 15# tank, pass through one-way valve 15, connect to 14# tank in reverse series, flow out from the bottom of 14# tank, pass through valve 1, pump 1, pump Enter the colored nickel-containing wastewater collection tank to complete the retention of nickel-containing wastewater; after the aluminum material is colored in 13# for 30s-15min, it will hang and drip for 30s, enter the 14# flowing water washing tank, wash for 1min, hang and drip for 30s, and enter the 15 #Flowing water washing tank, wash for 1min, hang and drip for 30s, enter the sealing tank, and complete the coloring and washing process; when the aluminum material is washed after coloring, the nickel sulfate and boric acid contained in the coloring solution are brought in and trapped in 14#, 15 #In the flowing water washi...

Embodiment 2

[0212] Embodiment 2 (nickel-containing wastewater collection system operation)

[0213] Operation process of the nickel-containing wastewater collection system: open valve 1, turn on pump 1, pump the colored nickel-containing wastewater discharged from the outlet of the 14# tank bottom into the nickel-containing wastewater collection tank for standby; complete the operation process of the nickel-containing wastewater collection system;

Embodiment 3

[0214] Embodiment 3 (nickel hydroxide recovery system operation)

[0215] Operation process of nickel hydroxide recovery system: open valve 2 and 3, close valve 4, turn on pump 2, pump nickel-containing waste water into the nickel hydroxide recovery tank; open valve 4 and 6, turn on pump 3 and 1# electric stirring, and circulate Reaction solution; slowly open valve 5, suck liquid ammonia into pump 3, and use high-speed rotation of pump 3 to fully mix the reaction solution; while adding liquid ammonia, check the pH value of the reaction solution, when the pH value reaches 8.5-9.0, close Valve 5, stop dosing, continue to circulate and stir for 1 hour; open 1# filter press, open valve 7, close valves 6 and 8, and separate nickel hydroxide from solid and liquid; after repeated spraying and rinsing of nickel hydroxide solid for 10 minutes, Recover nickel hydroxide products and complete the operation process of nickel hydroxide recovery system;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com