Integrated production system of circuit breaker

A technology for production systems and circuit breakers, which is applied in the manufacture of circuits, electrical components, and emergency protective devices, can solve problems such as low efficiency, high labor intensity, and increased labor and processing costs, so as to avoid improper assembly and effectively Human resources, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

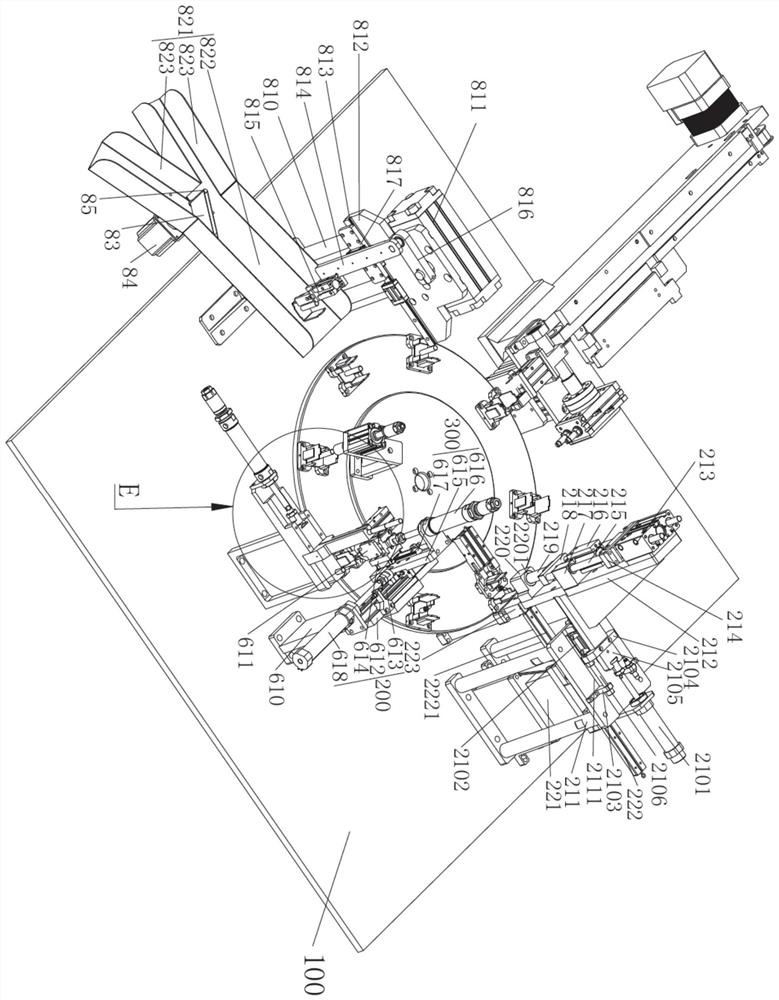

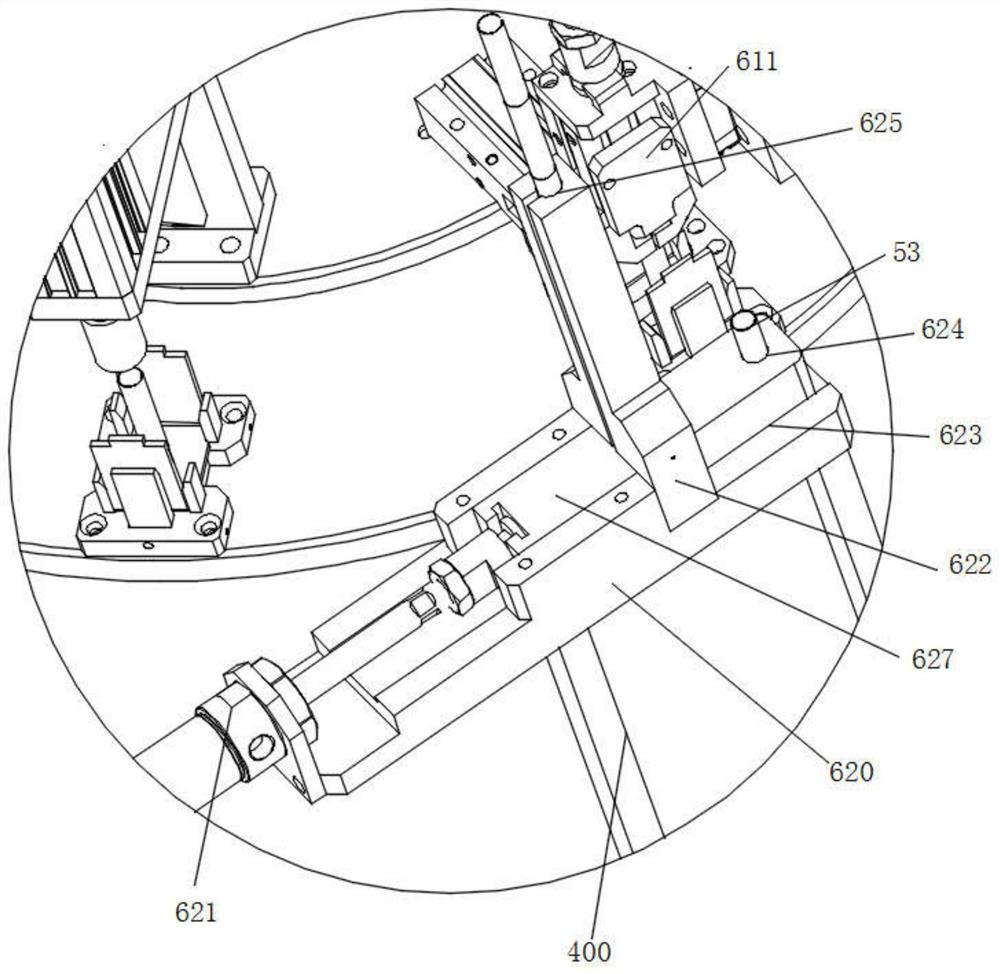

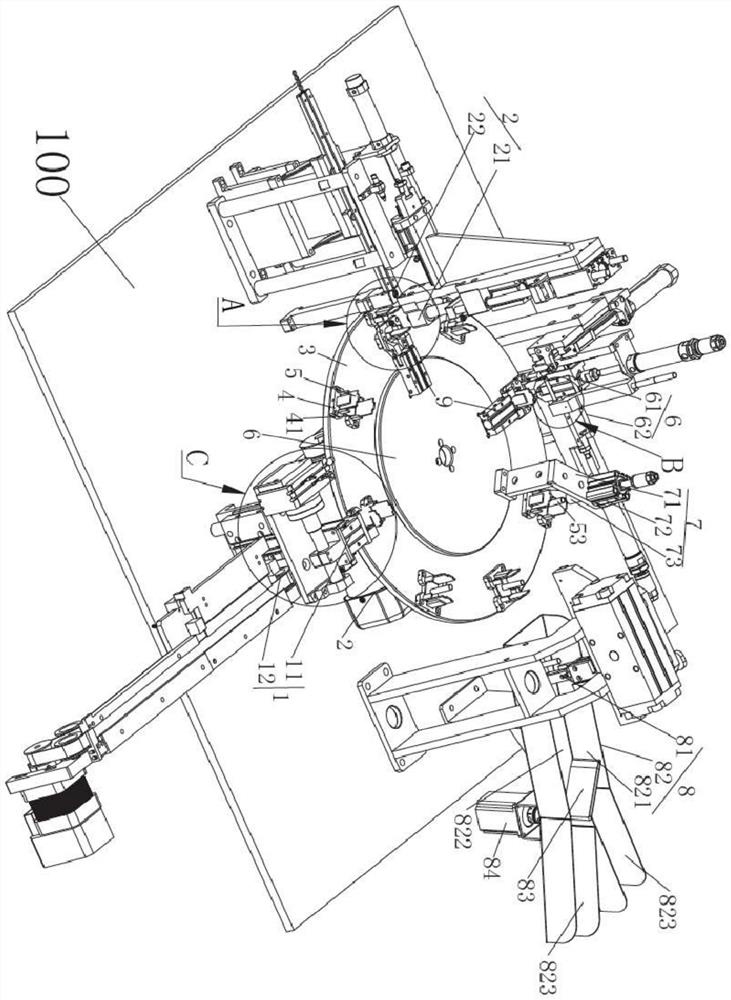

[0047] As shown in the drawings, an integrated production system for circuit breakers described in this embodiment is characterized in that it includes a PLC controller, a workbench 100, an indexing rotary plate 3, a fixed plate 6, and a conduit pressing mechanism 7. The indexing rotary drive device 2 installed on the workbench 100, the circuit breaker shell feeding mechanism 1, the dust-proof ring assembly mechanism 2, the conduit assembly mechanism 6 and the unloading mechanism 8, the indexing rotary disk 3 The central part is fixed on the rotating part of the indexing rotary drive device 2; the circuit breaker housing feeding mechanism 1, the dust-proof ring assembly mechanism 2, the conduit assembly mechanism 6 and the unloading mechanism 8 are located around the indexing rotary plate 3 side, and arranged in an annular array; the conduit pressing mechanism 7 is arranged between the conduit assembly mechanism 6 and the unloading mechanism 8, and the included angles between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com