Rapid sowing and seedling raising seed film

A technology of sowing seedlings and seed film, which is applied in the field of seedlings, can solve the problems of wasting seeds, uneven distribution of seeds, increasing labor force, etc., and achieves the effects of convenient use, no need for seedlings and transplanting, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

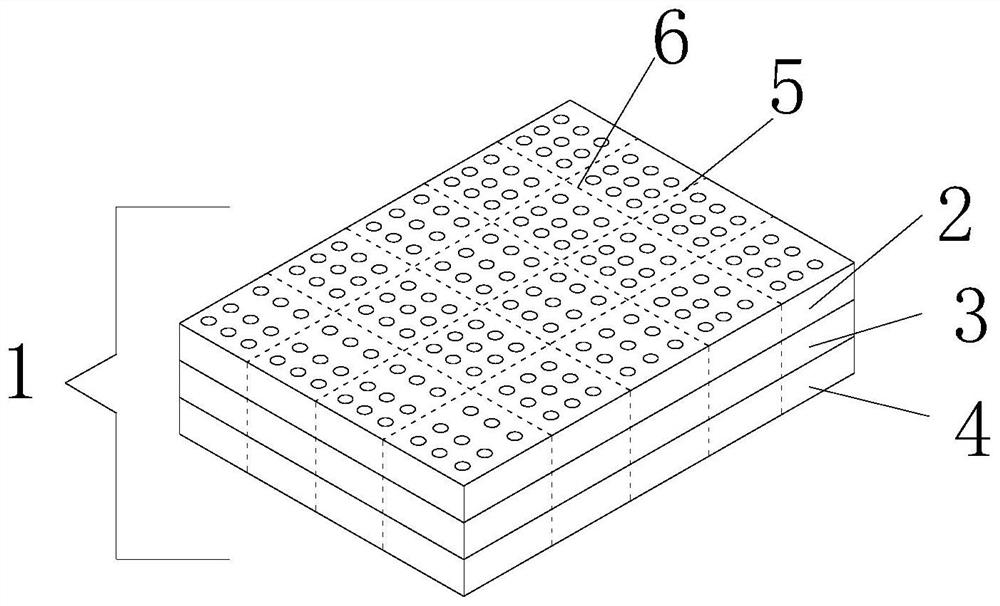

[0038] see Figure 1-Figure 4 , including a seed film 1, the seed film 1 is composed of three layers and is composed of a top layer 2, a middle layer 3, and a bottom layer 4, and the top of the top layer 2 is provided with a horizontal knife line 5 and a vertical knife line 6, and the horizontal knife line 5 and the longitudinal knife line 6 runs through the inside of the top layer 2, the middle layer 3, and the bottom layer 4 and extends to the outside of the bottom layer 4. The seed film 1 can be separated into multiple by the horizontal knife line 5 and the vertical knife line 6, and the horizontal knife line 5 and the vertical knife line 6 are connected to each other. Interlacing to form a unit cell, and at the same time, the horizontal knife cutting line 5 and the vertical knife cutting line 6 are interlaced to form a unit cell. It is more convenient to separate the seed film 1 through the horizontal knife cutting line 5 and the longitudinal knife cutting line 6, and then ...

Embodiment 2

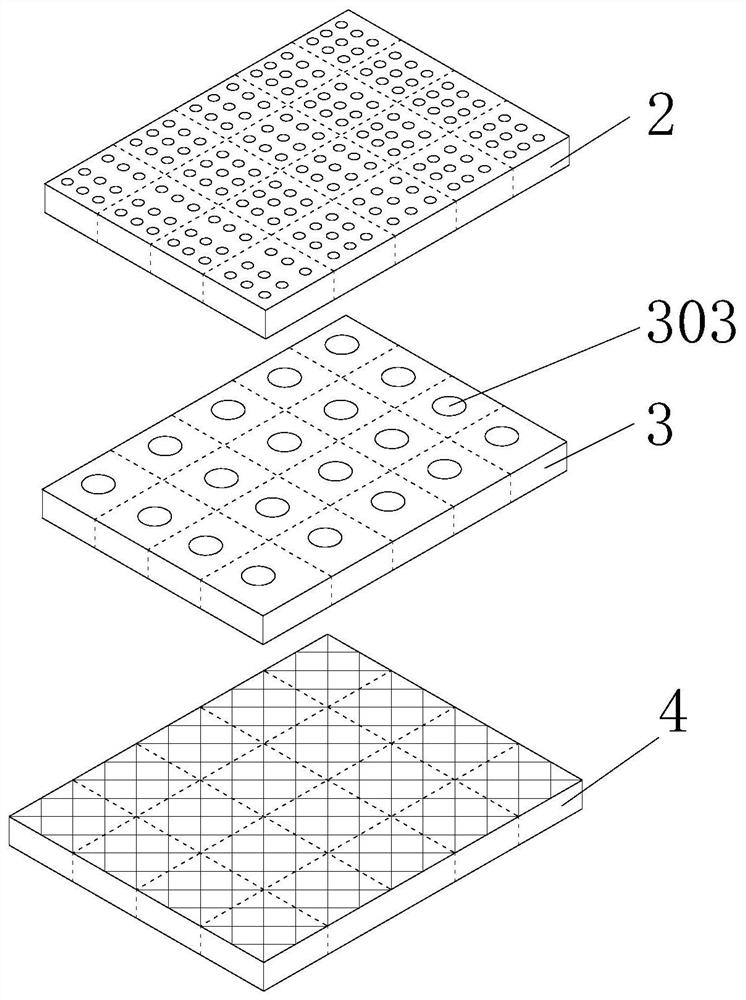

[0043] see Figure 5-Figure 6 , on the basis of Embodiment 1, the top of the middle layer 3 is provided with a first embedding groove 301, and the inside of the first embedding groove 301 can embed fertilizers, biological bacteria, drugs, etc., and the first embedding groove 301 is in the second The front side of the embedding groove 303 is not in contact with each other, the first embedding groove 301 and the second embedding groove 303 are in the same cell, so that the first embedding groove 301 and the second embedding groove 303 can pass through The horizontal knife cutting line 5 and the longitudinal knife cutting line 6 are torn off at the same time, the inner wall of the second embedding groove 303 is provided with a communication groove 302, and the inside of the communication groove 302 communicates with the inside of the second embedding groove 303;

[0044] Furthermore, after the medicine in the second embedding groove 303 is planted, the external water source enter...

Embodiment 3

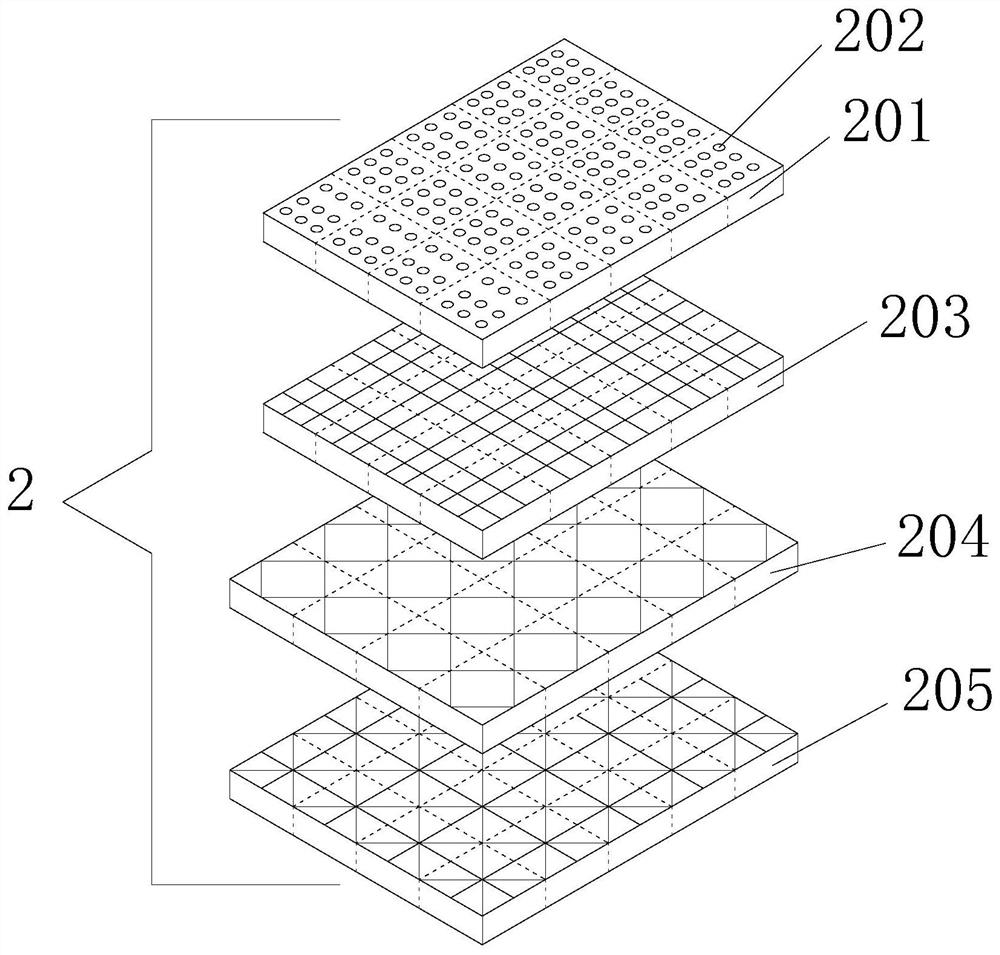

[0046] see Figure 7-Figure 10 , on the basis of Embodiment 1, the top of the top film 201 is provided with a groove 206, and at this time the top of the top film 201 has no air holes 202, and the groove 206 can make the external air more conveniently communicate with the air inside the film. exchange, so that the seeds remain active, and when the seeds are planted, the external water source can enter the interior of the film more smoothly through the groove 206 and be absorbed by the seeds, so that the seeds can grow more smoothly, increasing the seed life to a certain extent. Survival rate, the bottom of the top layer 2 is bonded to the top of the middle layer 3, and the middle layer 3 is a mesh structure;

[0047] The top of the bottom layer 4 is fixedly connected to the bottom of the middle layer 3, and the top of the bottom layer 4 is provided with a placement groove 7. The placement groove 7 runs through the inside of the bottom layer 4 and extends to the outside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com