Culture medium capable of adjusting water-gas configuration and manufacturing method thereof

A technology for cultivation substrates and manufacturing methods, which can be applied to medium, planting substrates, botanical equipment and methods, etc., and can solve problems such as difficult standardized management, product deviation, and poor results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

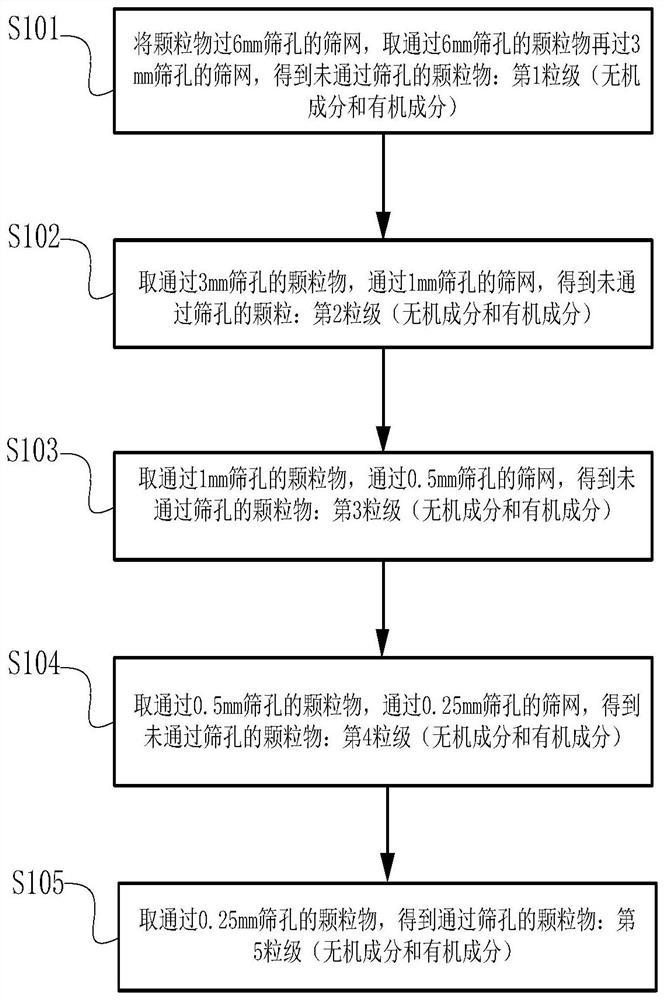

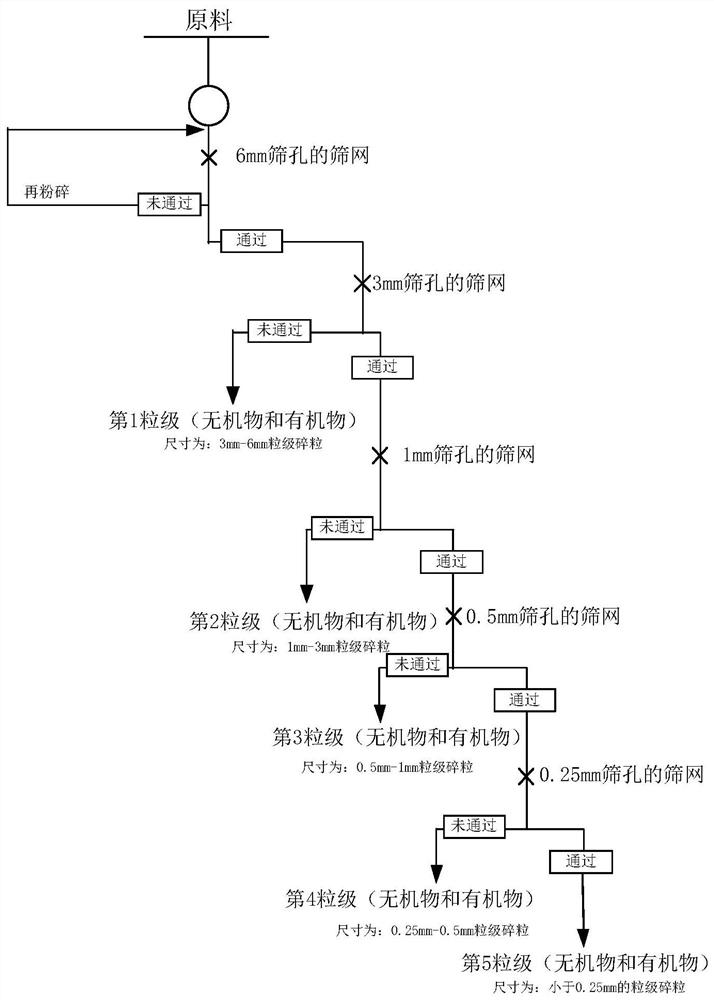

[0074] Pass the inorganic component raw material through a sieve with a 6mm sieve, take the crumbs that pass through a 6mm sieve and pass through a 3mm sieve to obtain the crumbs that do not pass through a sieve as the first grade; take the crumbs that pass through a 3mm sieve The crumbs passed through the sieve of 1mm sieve, and the crumbs that did not pass through the sieve were obtained as the second grade; the crumbs that passed through the 1mm sieve were passed through the sieve of 0.5mm sieve, and the crumbs that did not pass through the sieve were obtained. Crushed particles are the third grade; take the crushed particles that pass through the 0.5mm sieve and pass through the 0.25mm sieve, and the crushed particles that do not pass the sieve are the fourth grade; take the crushed particles that pass through the 0.25mm sieve , the crushed particles are all smaller than 0.25mm, and the crushed particles are the fifth grade.

[0075] Pass the organic component raw material...

Embodiment 2

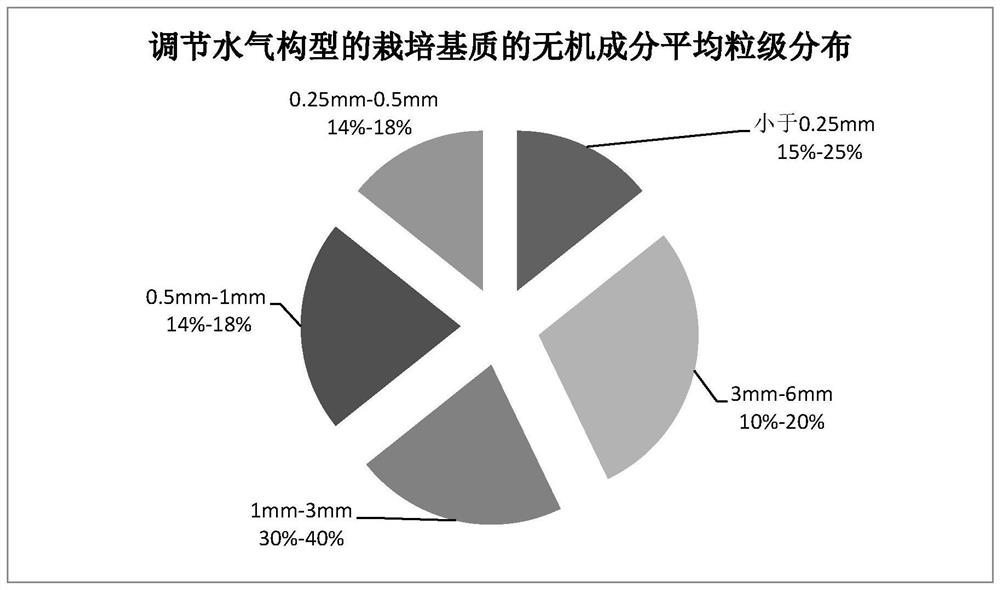

[0084] image 3 It is an average distribution and composition diagram of the inorganic component particles of the cultivation substrate for adjusting the water vapor configuration according to an embodiment of the present invention; Figure 4 It is a diagram of the average distribution and composition of the organic component particles of the cultivation substrate for adjusting the water vapor configuration according to an embodiment of the present invention. Such as image 3 , 4 shown. Proportioning the inorganic component particles and organic component particles respectively.

[0085] In Example 2, Table 1 is the seedling cultivation test of the cultivation substrate for adjusting the water-air configuration, providing a demonstration area of 3000 square meters, the cultivation method is strip cultivation, the furrow spacing is 110 cm, and the width of the upper opening of the cultivation groove is 30 cm. The width of the lower opening is 20cm, the depth of the groove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com