Layered high-strength and high-toughness composite material prepared based on wire-powder mixed deposition method

A composite material and high-strength technology, which is applied in the field of preparing high-strength and tough composite materials based on silk powder mixed deposition method, can solve the problems of complex transformation, difficulty in preparing high-strength and tough composite materials, and difficult control, so as to improve strength and break through the contradiction between strength and toughness Effect of confinement, high strength and high plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

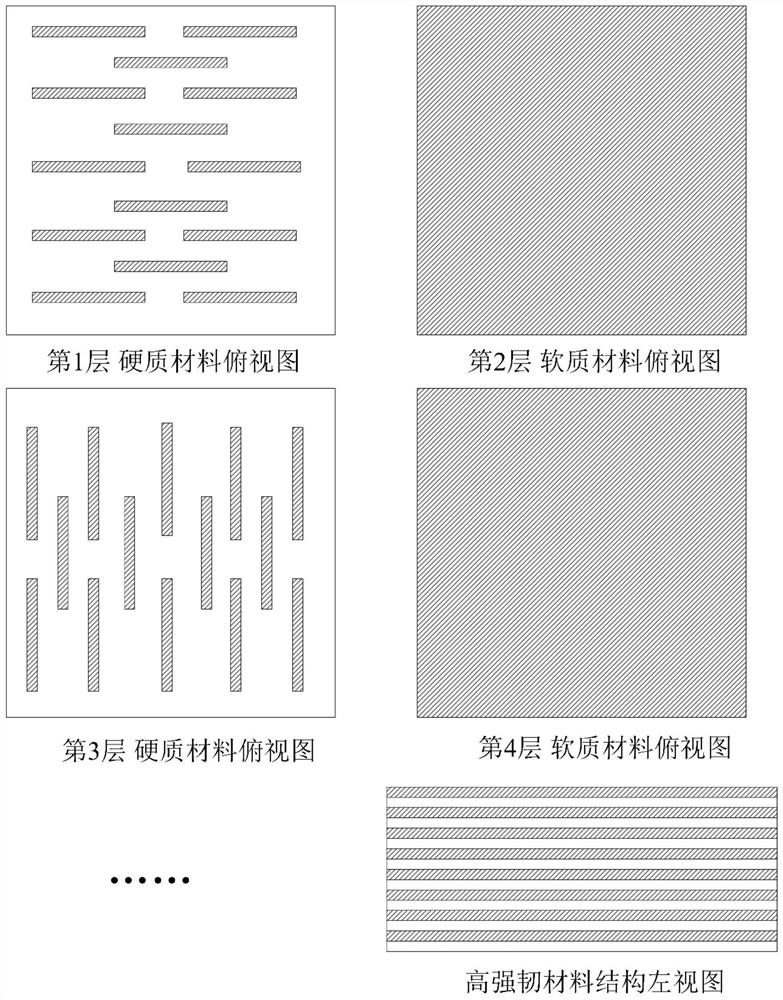

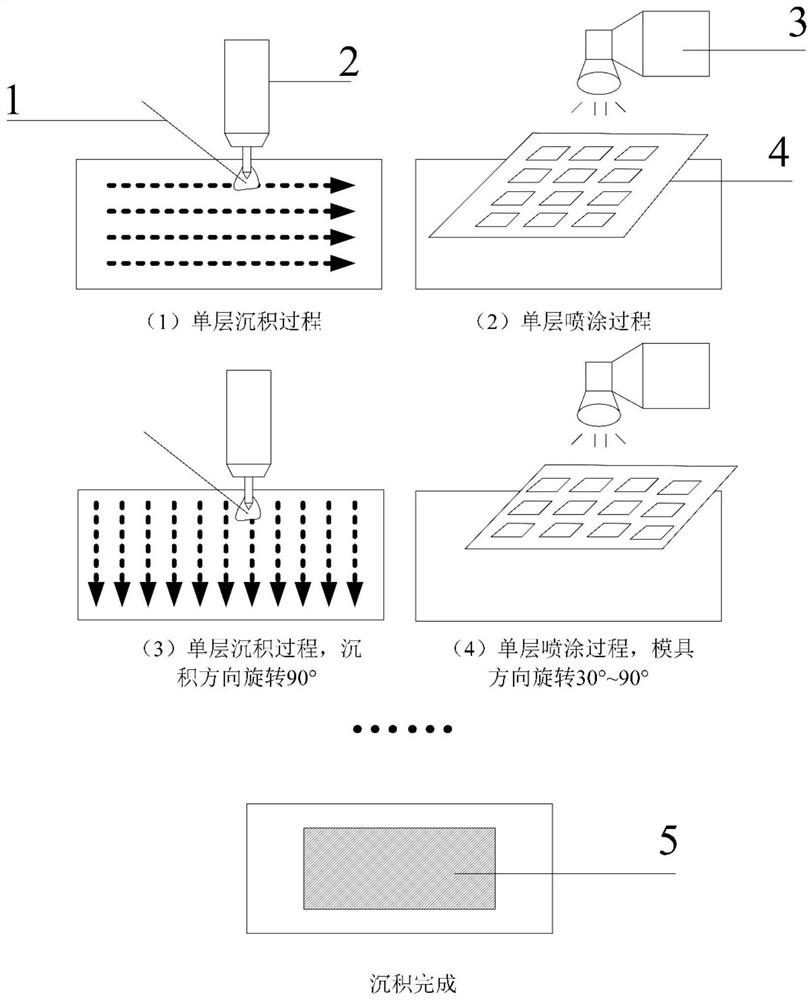

[0048] In this example, high-strength steel / B is prepared by using silk powder mixed deposition method 4 C High-strength and tough composite material, the wire material is high-strength steel ER130S-G, and the powder is B 4 C ceramic powder. The preparation process is as figure 1 As shown, among them, 1 is a high-strength steel wire, 2 is a fused wire additive manufacturing equipment, 3 is a spray gun, 4 is a hollowed-out mold, and 5 is a high-strength and tough composite material mixed and deposited with silk powder, including the following steps:

[0049] 1) Carry out structural design according to the actual part size, and construct a 3D CAD solid model according to the designed part structure, and slice and layer along the forming direction of the model; import the above slices into the computer to generate an implementable path;

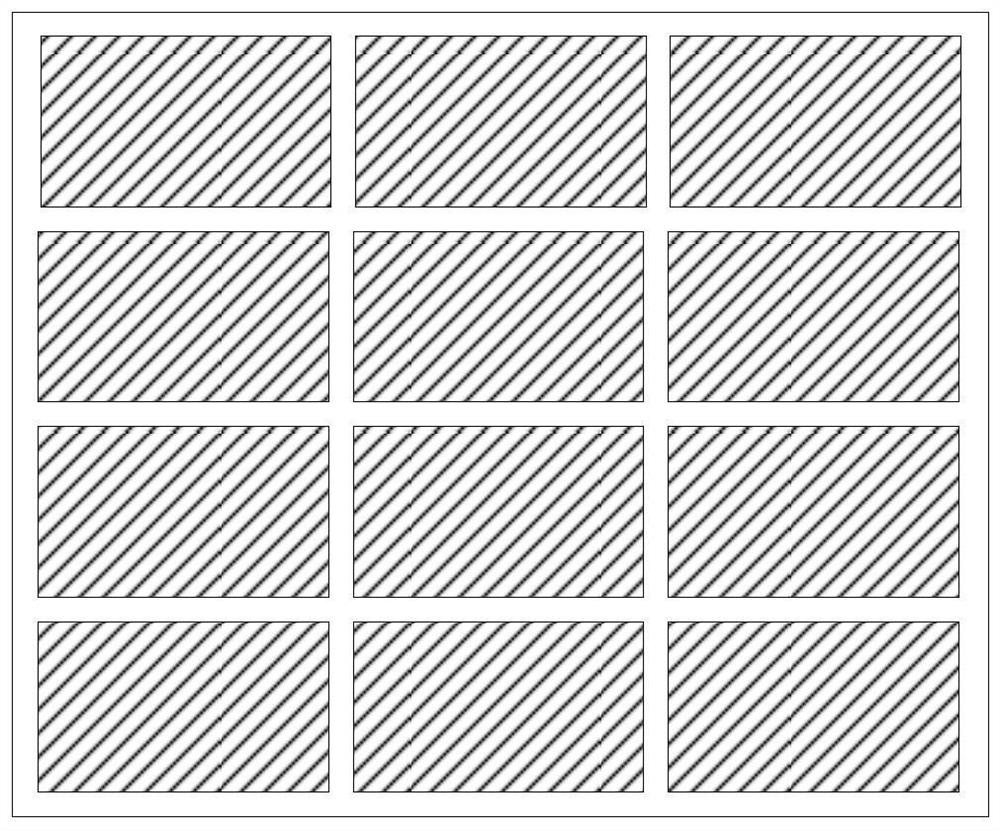

[0050] 2) Prepare the mold required for spraying according to the specific situation;

[0051] 3) Pre-treatment work such as grinding and cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com