LED product manufacturing method and LED product

A technology of LED chips and products, applied in the field of lighting, can solve problems such as uneven light color, and achieve the effect of simplifying the process flow, preventing sedimentation, and realizing controllable distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

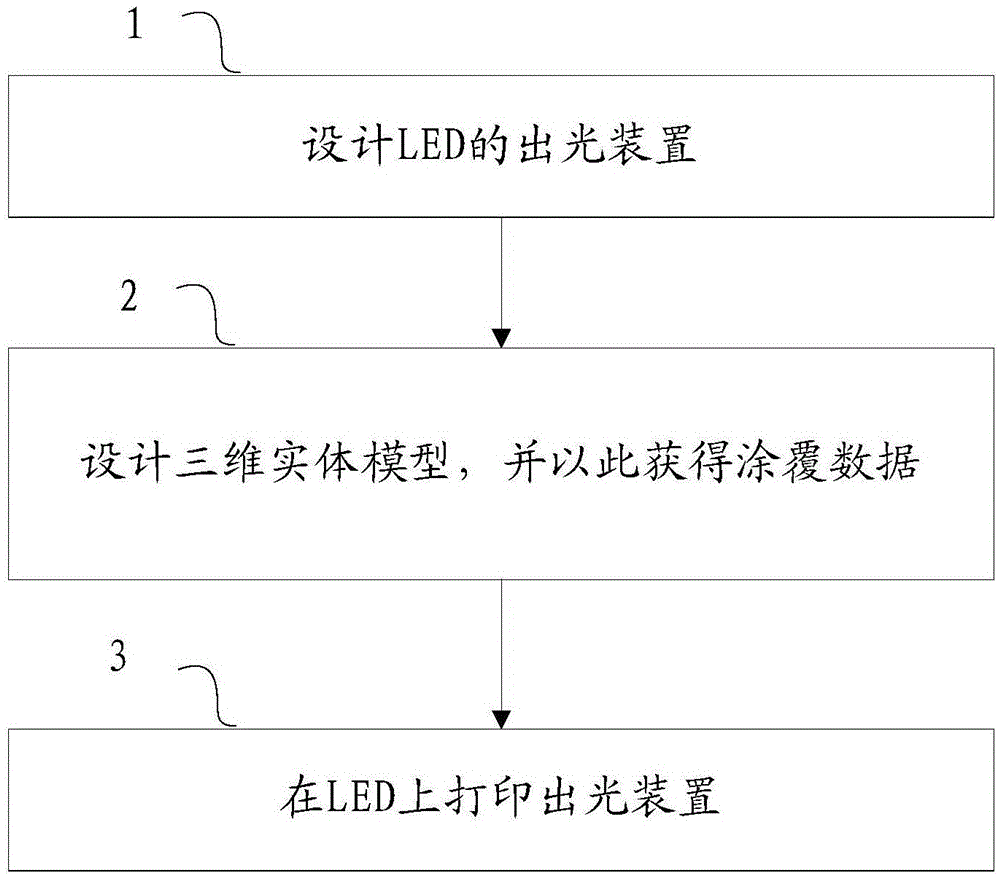

[0024] This example provides a LED product manufacturing method, the flow chart is as follows figure 2 As shown, it specifically includes the following steps.

[0025] Step 1: Design the light emitting device according to the light emitting requirements of LED products.

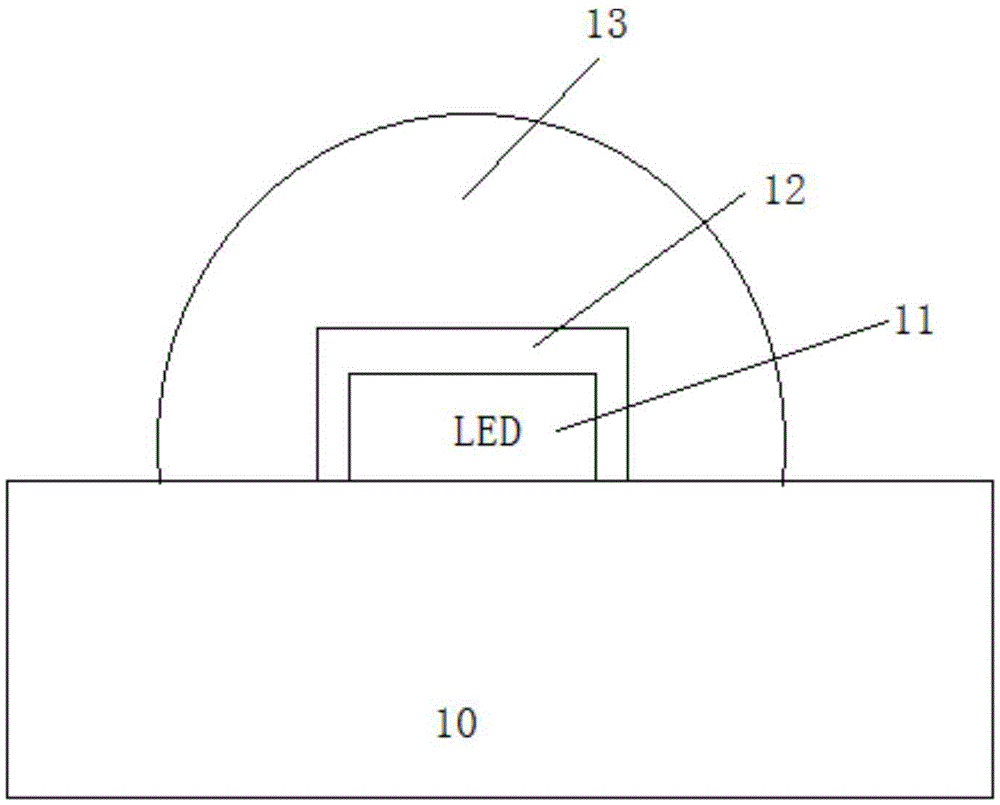

[0026] In order to make the light emitted by the LED chip output better, get the maximum utilization, and meet the design requirements in the lighting area, it is necessary to design the optical system of the LED. Among them, the design in the packaging process is called the primary optical design; the optical design outside the LED package is called the secondary optical design, also known as the secondary light distribution design, and the LED terminal product is completed after two designs Light mixing and homogenization. The color and energy conversion of the LED is realized by the phosphor layer, and the light mixing and uniform light of the LED are realized by the lens layer. In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com