Needle-like nano iron-based double-metal hydroxide and application thereof

A hydroxide, nano-iron technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, iron compound, nickel compound, etc., to achieve the effect of reducing pyrolysis temperature, improving pyrolysis efficiency, and enriching active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method includes:

[0038] (1) Soluble ferric salt, soluble divalent metal salt (one of nickel salt, manganese salt or cobalt salt) and urea are dissolved in ultrapure water to form a mixed solution. Wherein, the mass ratio of soluble ferric salt to soluble divalent metal salt is 1:(3-6), and the mass ratio of urea to metal salt is (1-3):1.

[0039] (2) Stir the mixed solution in a reactor at 100-160°C (for example, 100°C, 110°C, 120°C, 130°C, 140°C, 150°C, 160°C, etc.) Wash and centrifuge, disperse and dry with ethanol, and protect with nitrogen to obtain needle-shaped nanometer iron-based double metal hydroxide.

[0040] In this preparation method, the ratio of iron salt to divalent metal salt and the ratio of the sum of the two to urea are selected according to the structural characteristics and unit cell parameter characteristics of the above-mentioned needle-like nano-iron-based double metal hydroxide, and urea can effectively control the divalent m...

Embodiment 1

[0058] (1) Dissolve 0.7131g nickel dichloride hexahydrate, 0.1442g ferric chloride hexahydrate and 0.54g urea into ultrapure water, stir and react in a reactor at 160°C for 10h, the product is washed and centrifuged with distilled water, dispersed with ethanol and Drying, nitrogen protection throughout, to obtain needle-shaped nano-nickel-iron double metal hydroxide. Nickel hydroxide by-product present in the product.

[0059] The average length, diameter, and unit cell parameters of the needle-like nano-nickel-iron double hydroxide in this example were detected, and the results are shown in Table 1.

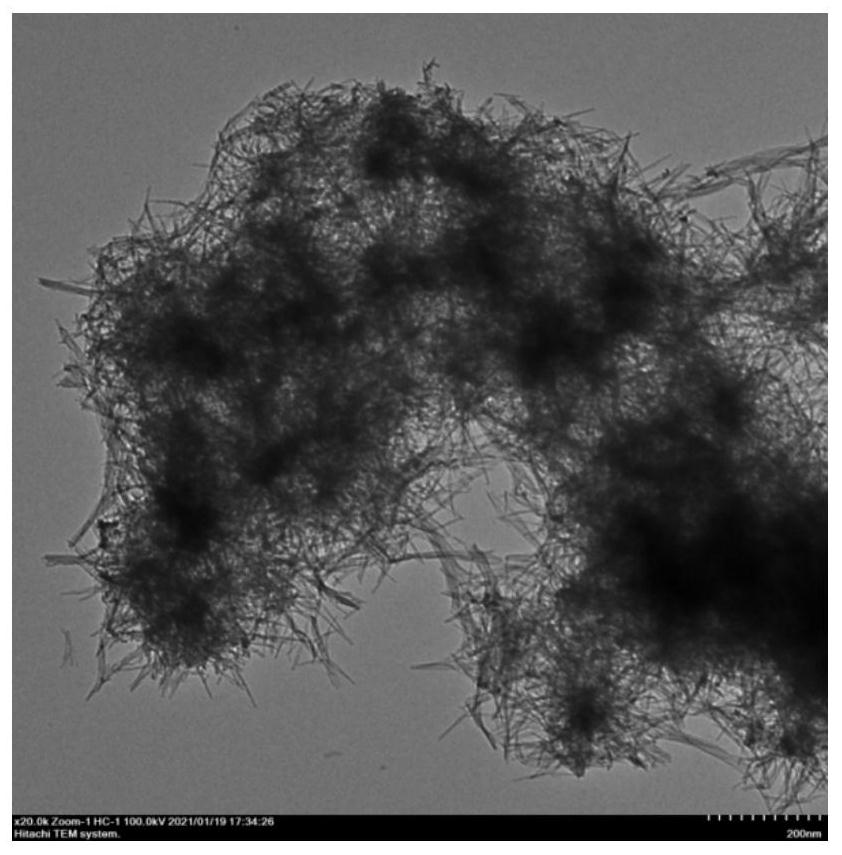

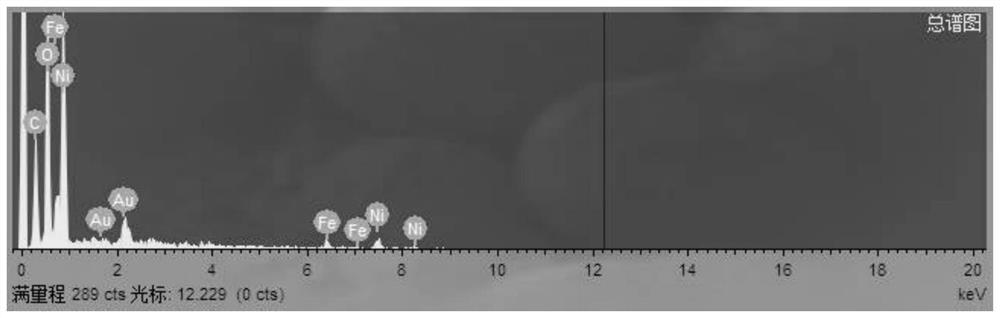

[0060] The transmission electron microscope figure, energy dispersive X-ray figure, X-ray diffraction figure and Fourier transform infrared spectrum figure of the acicular nano-nickel-iron double metal hydroxide of the present embodiment were taken, respectively as figure 2 , image 3 , Figure 4 and Figure 5 shown.

[0061] figure 2 It is a transmission electron micros...

Embodiment 2

[0068] (1) Dissolve 0.595g of cobalt dichloride, 0.1442g of ferric chloride hexahydrate and 0.46g of urea into ultrapure water, stir and react in a reactor at 160°C for 10 hours, wash and centrifuge the product with distilled water, disperse with ethanol and dry, The whole process is protected by nitrogen gas to obtain needle-shaped nanometer cobalt-iron double metal hydroxide.

[0069] (2) Evenly mix 10 grams of oil shale (TOC: 18.67%, HI: 651.18) with 0.5 grams of needle-shaped nano-cobalt-iron double metal hydroxide, place it in a closed reaction kettle at 300°C, and react for 90 minutes, The gas and liquid products were collected in situ, and the composition and distribution of the products were detected by gas chromatography. Solid organic matter was not detected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com