A construction method of fabric surface with passive daytime radiation cooling function and special wettability function

A technology for radiation cooling and functional fabrics, which is applied to plant fibers, light-resistant fibers, textiles, and papermaking. It can solve the problems of expensive preparation costs and complicated operation processes, and achieve controllable reaction conditions, easy process operation, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Let polydimethylsiloxane form an emulsion in water by means of ultrasound;

[0036] In one embodiment, this step can be specifically performed as follows: at a mass ratio of 1.5 wt%, polydimethylsiloxane is added to deionized water, and ultrasonicated at 40 °C for 3 h to form an emulsion.

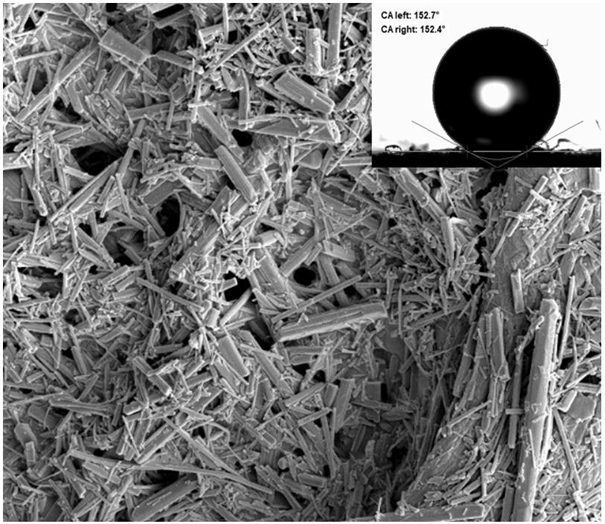

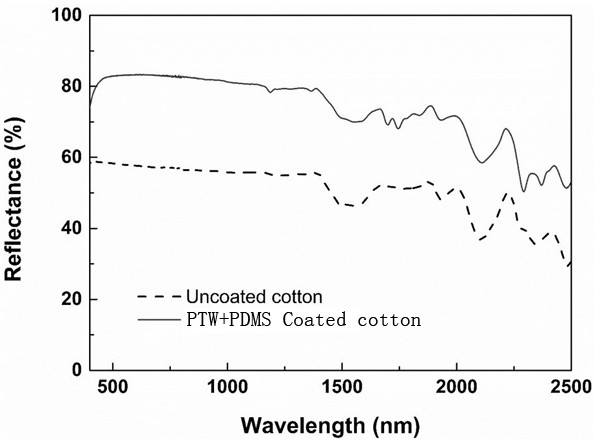

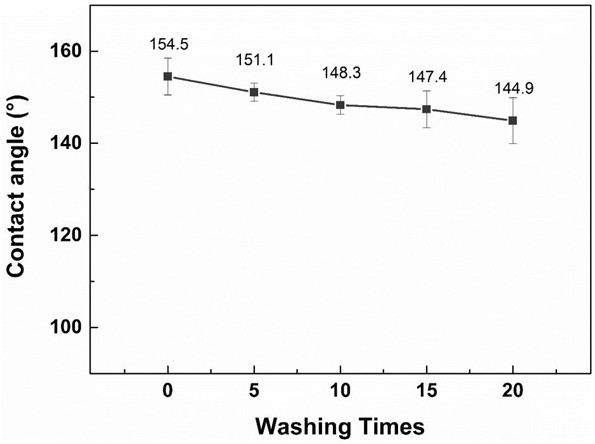

[0037] Step 2: The potassium titanate whiskers are uniformly dispersed in the emulsion in the previous step to form a suspension by means of ultrasound.

[0038]In one embodiment, this step can be specifically performed as follows: first, cut 4 pieces of cotton cloth according to the size of 5×5 cm, and put them in a beaker, and then undergo ultrasonication with acetone, deionized water, and absolute ethanol for 10 minutes, and place the Dry in an oven at 60°C and cool for later use. Weigh 0.5 g of potassium titanate whiskers on an electronic balance for later use, place the emulsion obtained in step 1 in an ultrasonic environment, slowly add the weighed potassium titanate w...

Embodiment 2

[0043] Step 1: Let polydimethylsiloxane form an emulsion in water by means of ultrasound;

[0044] In one embodiment, this step can be specifically performed as follows: Add polydimethylsiloxane to deionized water at a mass ratio of 0.5 wt%, and ultrasonicate at 30°C for 10 h to form an emulsion.

[0045] Step 2: The potassium titanate whiskers are uniformly dispersed in the emulsion in the previous step to form a suspension by means of ultrasound.

[0046] In one embodiment, this step can be specifically performed as follows: first, cut 4 pieces of cotton cloth according to the size of 5×5 cm, and put them in a beaker, and then undergo ultrasonication with acetone, deionized water, and absolute ethanol for 10 minutes, and place the Dry in an oven at 60°C and cool for later use. Weigh 0.5 g of potassium titanate whiskers on an electronic balance for later use, place the emulsion obtained in step 1 in an ultrasonic environment, slowly add the weighed potassium titanate whisker...

Embodiment 3

[0048] Step 1: Let polydimethylsiloxane form an emulsion in water by means of ultrasound;

[0049] In one embodiment, this step can be specifically performed as follows: Add polydimethylsiloxane to deionized water at a mass ratio of 2.0 wt%, and ultrasonicate at 50°C for 0.5 h to form an emulsion.

[0050] Step 2: The potassium titanate whiskers are uniformly dispersed in the emulsion in the previous step to form a suspension by means of ultrasound.

[0051] In one embodiment, this step can be specifically performed as follows: first, cut 4 pieces of cotton cloth according to the size of 5×5 cm, and put them in a beaker, and then undergo ultrasonication with acetone, deionized water, and absolute ethanol for 10 minutes, and place the Dry in an oven at 60°C and cool for later use. Weigh 0.5 g of potassium titanate whiskers on an electronic balance for later use, place the emulsion obtained in step 1 in an ultrasonic environment, slowly add the weighed potassium titanate whiske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com