Foamed aluminum building non-dismantling formwork

A technology that avoids demolition of formwork and building formwork. It is applied in the direction of buildings, building components, and building structures. It can solve the problems of adhesive glue failure and falling off, increasing the building area, and long construction period. It is not easy to fall off, the construction process is simplified, and fire prevention good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

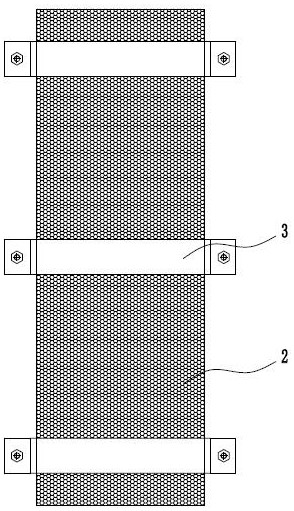

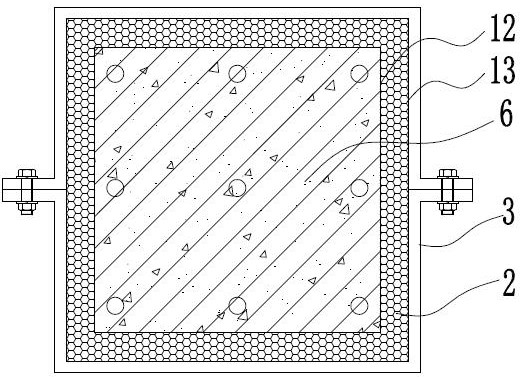

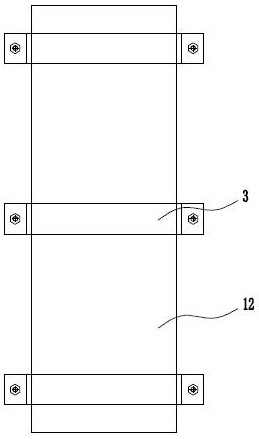

[0042] Such as Figure 1~Figure 2 , Figure 11~Figure 12 As shown, the foamed aluminum building demolition-free formwork preferably implemented in the present invention includes a building formwork 1. The building formwork 1 is a plate structure or a columnar structure, and the columnar structure has a hollow cavity 11 that can pour reinforced concrete 6 inside. It is characterized in that, The main body of the building formwork 1 is made of foamed aluminum 2, and the foamed aluminum 2 is made of aluminum alloy through a foaming process; The side is the template composite surface 12, and the outer side not in contact with the concrete 6 is the template decorative s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com