Dry burning test device for single-sided conductive PTC heating plate

A test device and heating plate technology, which is applied in the direction of measuring device, measuring electricity, measuring electric variables, etc., can solve the problems of low efficiency and achieve the effect of reducing test time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following is attached Figure 1-7 The application is described in further detail.

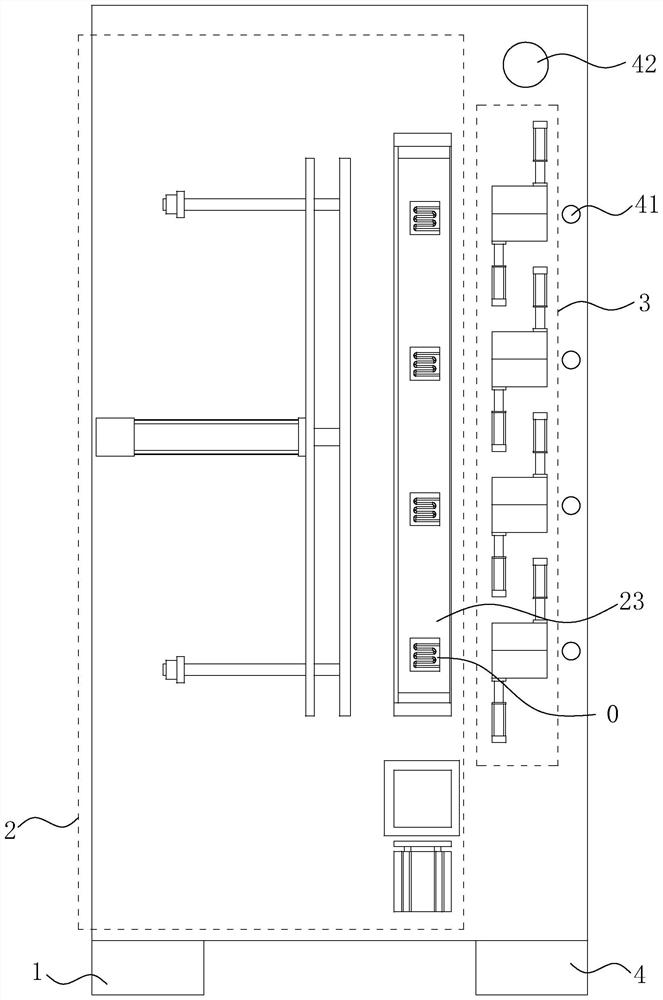

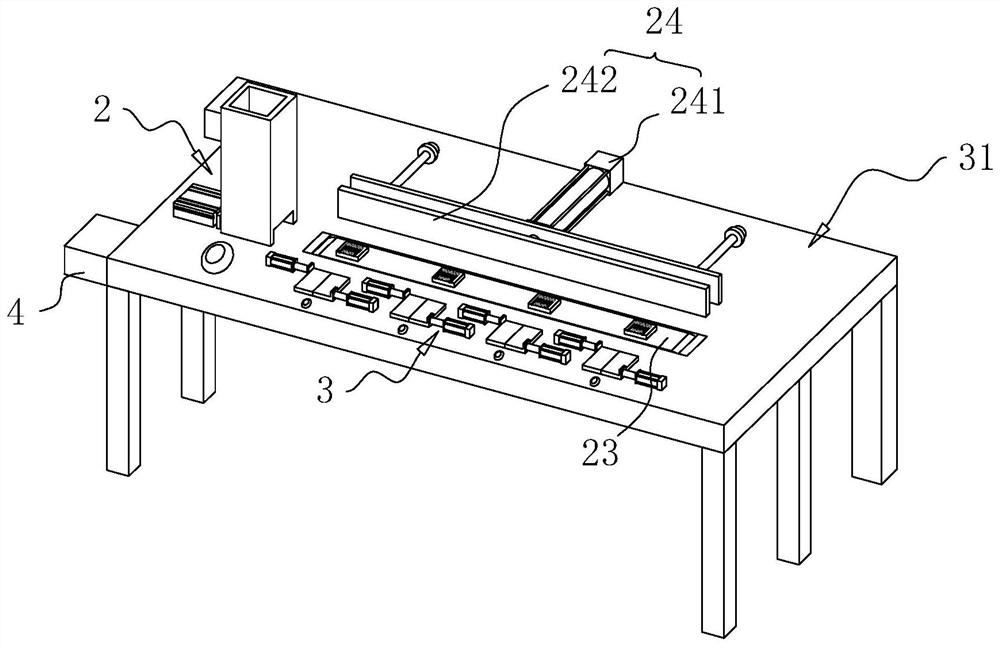

[0056] The embodiment of the present application discloses a dry burning test device of a single-sided conductive PTC heating plate. refer to figure 1 and figure 2 , mainly including: a control unit 1 for controlling the operating state of the device, a transfer unit 2 for transferring a plurality of PTC heating plates 0 to a test position, a test unit 3 for realizing the purpose of heating and testing the PTC heating plates 0 and Energy supply unit 4 for power supply.

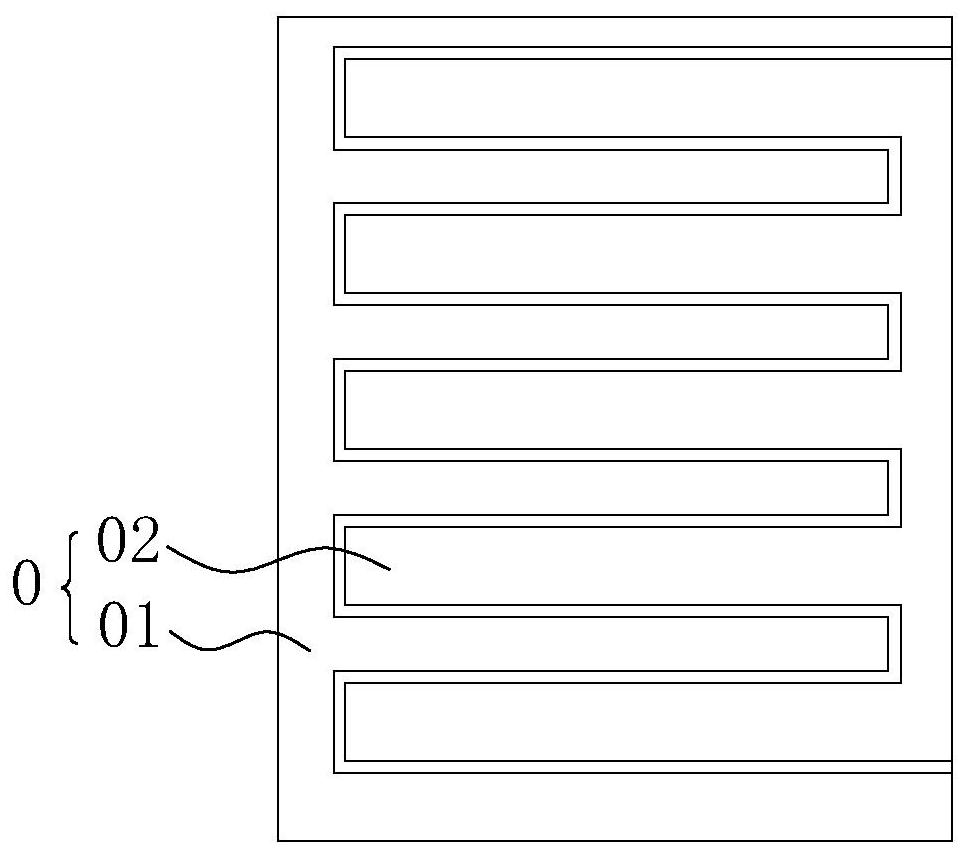

[0057] refer to image 3 , wherein in the embodiment of this application, only one side of the PTC heating plate 0 is a conductive surface, and the conductive surface is respectively provided with a forward electrical connection terminal 01 and a reverse electrical connection terminal, and a forward electrical connection terminal 01 and a reverse electrical connection terminal. The insulation materials are sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com